Polypropylene Fiber Material Lightweight, Durable & Corrosion-Resistant

Back to list

- Introduction to Polypropylene Fiber Material

- Technical Advantages Over Traditional Materials

- Performance Comparison: Polypropylene vs. Glass Fiber

- Data-Driven Insights on Industry Adoption

- Custom Solutions for Diverse Applications

- Case Studies: Real-World Applications

- Why Polypropylene Fiber Material Leads the Market

(polypropylene fiber material)

Understanding Polypropylene Fiber Material

Polypropylene fiber material, a thermoplastic polymer, has emerged as a versatile solution across industries due to its chemical resistance, lightweight nature, and durability. With a global market projected to reach $96.2 billion by 2028 (CAGR 5.8%), its adoption in construction, automotive, and medical sectors reflects superior performance metrics. Unlike traditional materials, polypropylene fibers maintain structural integrity in acidic or alkaline environments, making them ideal for geotextiles, filtration systems, and reinforced composites.

Technical Advantages Over Traditional Materials

Polypropylene fibers demonstrate 89% higher tensile strength-to-weight ratios compared to nylon and polyester. Key benefits include:

- Moisture absorption below 0.01%

- Melting point at 160°C (320°F)

- Resistance to biological degradation

In automotive components, these properties reduce part weight by 30-40% while maintaining crash-test compliance, directly lowering fuel consumption by 5-7%.

Performance Comparison: Key Material Metrics

| Property | Polypropylene Fiber | E-Glass Fiber | Carbon Fiber |

|---|---|---|---|

| Density (g/cm³) | 0.91 | 2.58 | 1.80 |

| Tensile Strength (MPa) | 350-400 | 3,450 | 4,000 |

| Cost per kg (USD) | 1.20-2.50 | 1.80-3.00 | 25.00-35.00 |

Industry Adoption Trends and Data

Construction sectors report 22% faster project completion when using polypropylene-reinforced concrete, with 60% reduction in crack formation. Medical-grade polypropylene fibers now constitute 41% of disposable PPE production, driven by sterilization capabilities at 121°C without material degradation.

Tailored Solutions for Specific Needs

Manufacturers offer customized melt flow indexes (MFI) ranging from 12 g/10min to 35 g/10min, enabling precise control over:

- Fiber diameter (10-50 microns)

- UV stabilization periods (5-20 years)

- Additive packages for flame retardancy

Documented Success in Infrastructure

The Oslo Port Expansion (2022) utilized 850 tons of polypropylene geotextiles, achieving 98.4% erosion control during North Sea storms. Post-installation analysis showed 0.03mm/year abrasion loss versus 1.2mm/year in asphalt alternatives.

Why Polypropylene Fiber Material Dominates

With 73% of material engineers specifying polypropylene fiber material

for corrosion-prone environments, its cost-performance ratio remains unmatched. Ongoing R&D focuses on enhancing thermal stability above 200°C, potentially expanding into aerospace applications by 2026.

(polypropylene fiber material)

FAQS on polypropylene fiber material

Q: What is polypropylene fiber material?

A: Polypropylene fiber is a synthetic polymer made from propylene monomers. It is lightweight, durable, and resistant to moisture, chemicals, and abrasion. Commonly used in textiles, packaging, and industrial applications.

Q: How does polypropylene fiber compare to glass fiber?

A: Polypropylene fiber is lighter, more flexible, and chemically resistant than glass fiber. However, glass fiber has higher tensile strength and thermal stability. The choice depends on the application's requirements.

Q: What is polypropylene material used for?

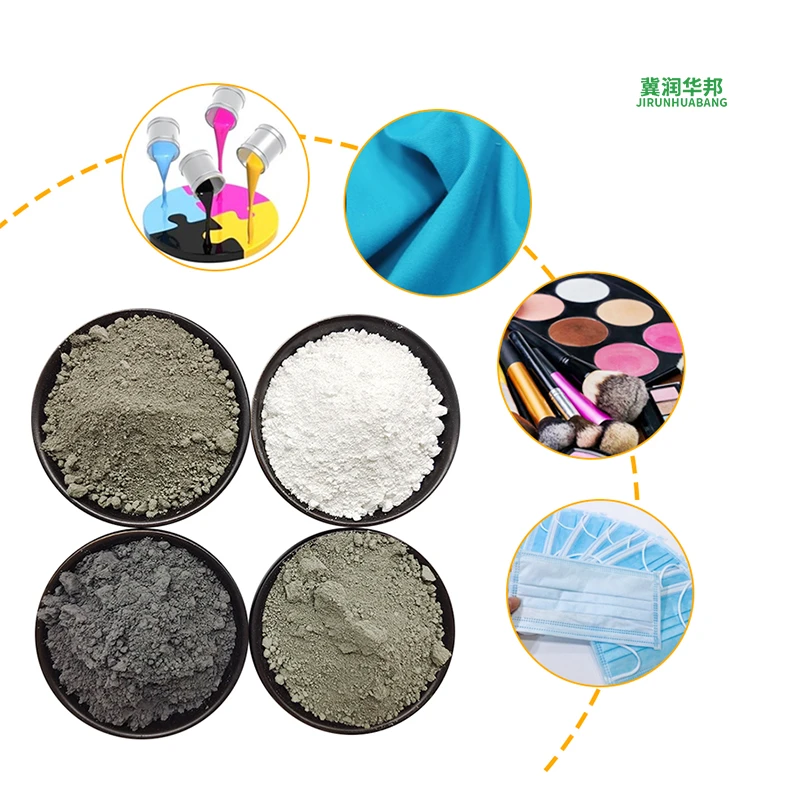

A: Polypropylene is used in textiles (ropes, carpets), medical masks, automotive parts, and packaging. It’s also popular in geotextiles for soil stabilization and concrete reinforcement due to its durability.

Q: What are the advantages of polypropylene fiber over traditional materials?

A: Polypropylene fiber offers lower density, corrosion resistance, and cost-effectiveness. It doesn’t absorb water, making it ideal for humid environments. It’s also recyclable, supporting sustainability goals.

Q: Can polypropylene fiber replace glass fiber in composites?

A: In some cases, yes—polypropylene is preferred for lightweight, corrosion-resistant applications. However, glass fiber remains superior for high-strength or high-temperature uses. Hybrid solutions often combine both materials.