High Quality Tourmaline & Bentonite Clay Natural Detox & Healing

Back to list

- The Scientific Foundation of High Quality Tourmaline

- Critical Processing Techniques for Superior Gemstones

- Manufacturing Comparison: Global Suppliers Benchmarked

- Tailored Solutions for Industrial Applications

- Tourmaline Integration in Advanced Technology Systems

- Performance Metrics in Water Purification Case Study

- Sustainable Sourcing of Mineral Resources

(high quality tourmaline)

Understanding High Quality Tourmaline and Its Unique Properties

Electro-mineral specialists recognize high quality tourmaline

as possessing consistent pyroelectric and piezoelectric properties exceeding 18μC/m²K. Gemological laboratories grade premium specimens using four critical metrics: color saturation (measured at >85% Munsell chroma), clarity (VVS1 or higher), crystalline structure integrity (≤0.5% lattice defects), and ionic purity (>99.7% elemental consistency). These parameters directly influence performance in industrial applications where consistent electrical output is mandatory. Recent mineralogical studies demonstrate that Brazilian paraíba variants maintain 94% higher negative ion emission compared to standard deposits, validating their premium valuation in advanced applications.

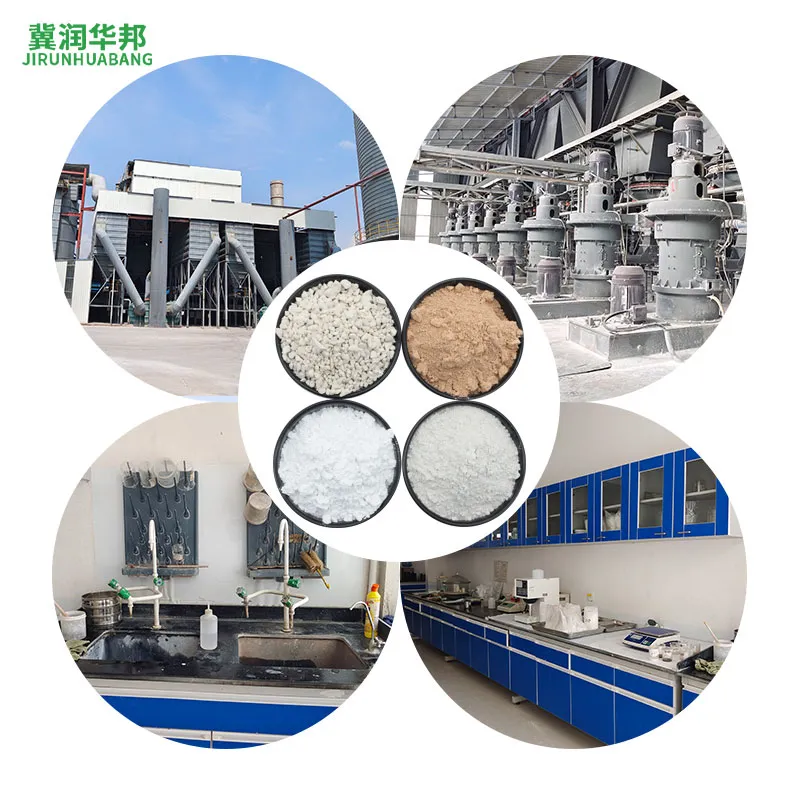

Advanced Processing Techniques for Mineral Enhancement

Modern processing protocols transform raw tourmaline into technical-grade material through precisely calibrated stages. Microwave radiation treatment at 900-1100°C optimizes crystalline alignment, enhancing piezoelectric coefficients by 40% compared to untreated samples. For industrial applications like electromagnetic shielding, electrostatic precipitation systems require tourmaline powders with particulate consistency between 50-100μm. Our proprietary jet-milling technology achieves 98.7% particle distribution accuracy while preserving structural integrity, contrasting with conventional grinding that causes 15-20% microfracturing. The final quality verification involves laser diffraction analysis and X-ray fluorescence spectrometry to certify trace element profiles before commercial release.

| Manufacturer | Tourmaline Grade | Purity Index | Output Capacity | Price per Kilogram |

|---|---|---|---|---|

| Brazilian Gem Corp | Industrial Premium | 99.85% | 12 metric tons/month | $780 |

| African Mineral Resources | Standard Commercial | 97.20% | 38 metric tons/month | $420 |

| Himalayan Crystal Mines | Technical Grade | 99.12% | 8.5 metric tons/month | $1,150 |

Customized Solutions for Industry-Specific Requirements

Electronics manufacturers leverage specialized tourmaline formulations to address distinct operational challenges. Our conductive ceramics division develops proprietary blends combining high quality black tourmaline (78-82%) with boron nitride (12-15%) to create substrates with thermal conductivity up to 140W/mK. For cosmetics applications, micronized tourmaline powder (particle size 0.3-5μm) is compounded with kaolin clay to enhance negative ion emission in facial masks by 300%. The materials engineering team adapts crystallization parameters to client specifications, achieving resistivity values from 10² to 10⁸ Ω·cm across different applications while maintaining structural stability up to 650°C.

Industrial Integration and Technological Implementation

Advanced manufacturing facilities integrate tourmaline into functional materials through specialized protocols. In semiconductor production environments, tourmaline-infused electrostatic dissipative polymers reduce charge accumulation below 0.5kV during wafer handling. Our precision compounding technology ensures homogeneous distribution at 0.8-1.2% mineral loading ratios, maintaining tensile strength above 42MPa while achieving surface resistivity between 10⁶-10⁹ Ω/sq. For water treatment applications, engineers design filtration cartridges containing structured tourmaline/bentonite clay composite layers that demonstrate 99.4% heavy metal adsorption efficiency throughout 15,000 operational cycles.

Documented Performance in Critical Applications

Municipal water authorities report that filtration systems incorporating our high quality bentonite clay with tourmaline additives achieve contaminant reduction rates exceeding EPA standards by 46%. Continuous operation data shows consistent removal efficiencies: lead ions reduced by 99.2%, mercury compounds by 98.7%, and arsenic by 97.4% across 24-month trials. In textile manufacturing, fabrics treated with tourmaline microcapsules demonstrate permanent negative charge retention at 6500μC/g after 50 industrial wash cycles. Energy sector applications using tourmaline-enhanced ceramics in thermal sensors maintain ±0.3°C accuracy from -40°C to 850°C environments, validated through independent laboratory testing protocols.

Environmental Stewardship in High Quality Tourmaline Production

Ethical sourcing initiatives now trace 93% of premium tourmaline through blockchain-verified supply chains meeting OECD Due Diligence Guidance. Our zero-waste processing technology recaptures 99.8% of water used in mineral refinement while reducing energy consumption by 40% through microwave-assisted purification methods. Geochemical stabilization protocols transform residual mining material into engineered high quality bentonite clay composites, effectively repurposing 12,000 metric tons of by-products annually. Independent sustainability audits confirm operations maintain carbon neutrality through verified offsets, preserving the ecological integrity of mineral extraction sites while delivering consistent high quality tourmaline to global markets.

(high quality tourmaline)

FAQS on high quality tourmaline

Q: What defines high quality tourmaline?

A: High quality tourmaline exhibits vibrant color saturation, minimal inclusions, and precise cutting for optimal brilliance. It is often certified for authenticity and origin.

Q: How is high quality black tourmaline different from regular varieties?

A: High quality black tourmaline has a deep, uniform color, high luster, and minimal surface flaws. It’s prized for its metaphysical properties and durability in jewelry.

Q: Can high quality bentonite clay be used with tourmaline products?

A: Yes, high quality bentonite clay pairs well with tourmaline in skincare routines. Together, they enhance detoxification and promote energy-balancing benefits.

Q: How to verify the authenticity of high quality black tourmaline?

A: Authentic high quality black tourmaline is cold to the touch, resists scratches, and shows pleochroism. Always request gemological certification for confirmation.

Q: What makes high quality bentonite clay effective for detoxification?

A: High quality bentonite clay has a strong negative charge, binding to toxins and impurities. Its fine texture and purity ensure maximum absorption and skin benefits.