Polvo de turmalina de Runhuabang con diferentes especificaciones para la industria textil del caucho

In the rubber industry, tourmaline powder is used as a reinforcing agent and filler material. Different grades of tourmaline powder, characterized by varying particle sizes and purity levels, are tailored to meet the requirements of various rubber formulations. Smaller particle sizes, for instance, provide better dispersion within the rubber matrix, enhancing its mechanical strength and wear resistance. Higher purity levels, on the other hand, minimize the risk of contamination and improve the overall performance of the rubber compound.

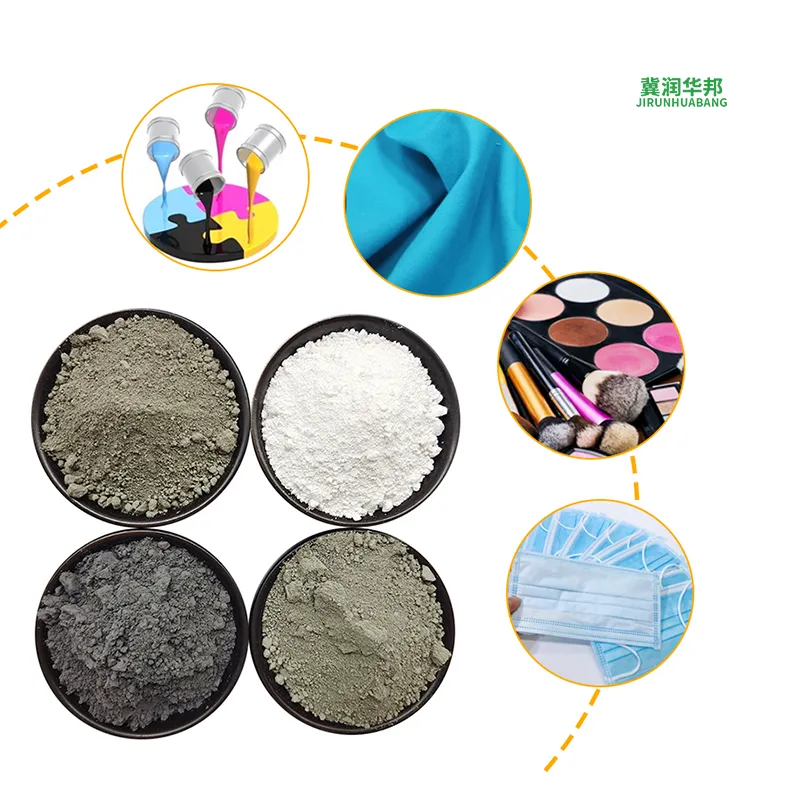

The textile industry leverages the unique electrical properties of tourmaline powder to create innovative fabric treatments. Tourmaline-infused fibers, for example, exhibit enhanced moisture-wicking capabilities and improved thermal regulation, making them ideal for athletic wear and performance clothing. The specifications of the tourmaline powder used in these applications are carefully controlled to ensure consistent performance and consumer satisfaction.

Moreover, the ability to customize tourmaline powder specifications according to industry needs opens up new possibilities for innovation. In the rubber industry, for instance, tourmaline powder can be formulated to enhance the flame retardancy or antistatic properties of rubber products. Similarly, in textiles, tourmaline powder can be tailored to provide UV protection or antimicrobial properties.

In conclusion, the versatility of tourmaline powder specifications makes it an indispensable material in both rubber and textile industries. By carefully selecting and formulating tourmaline powder according to specific application requirements, manufacturers can achieve enhanced product performance and meet evolving market demands.

| Place of Origin | China |

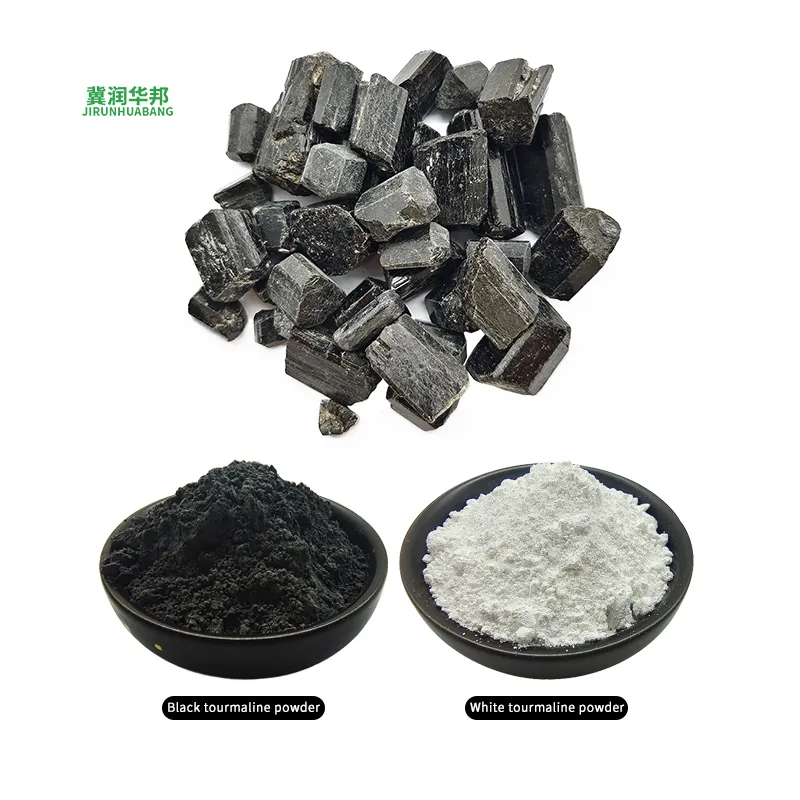

| Color | White/Black |

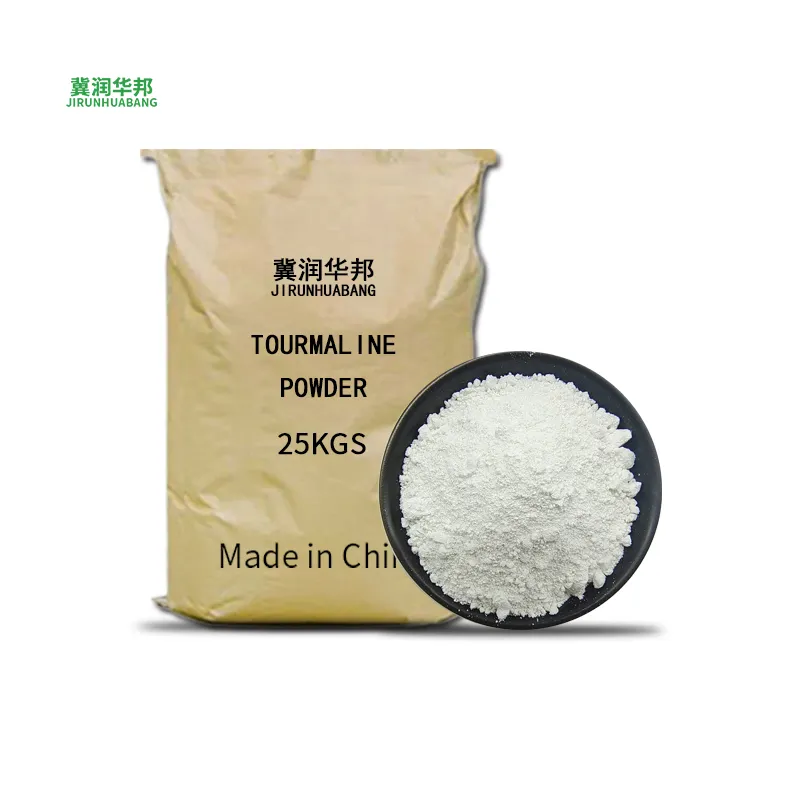

| Shape | Powder/particle |

| Purity | 95-99% |

| Grade | cosmetics grade/industrial Grade/food grade |

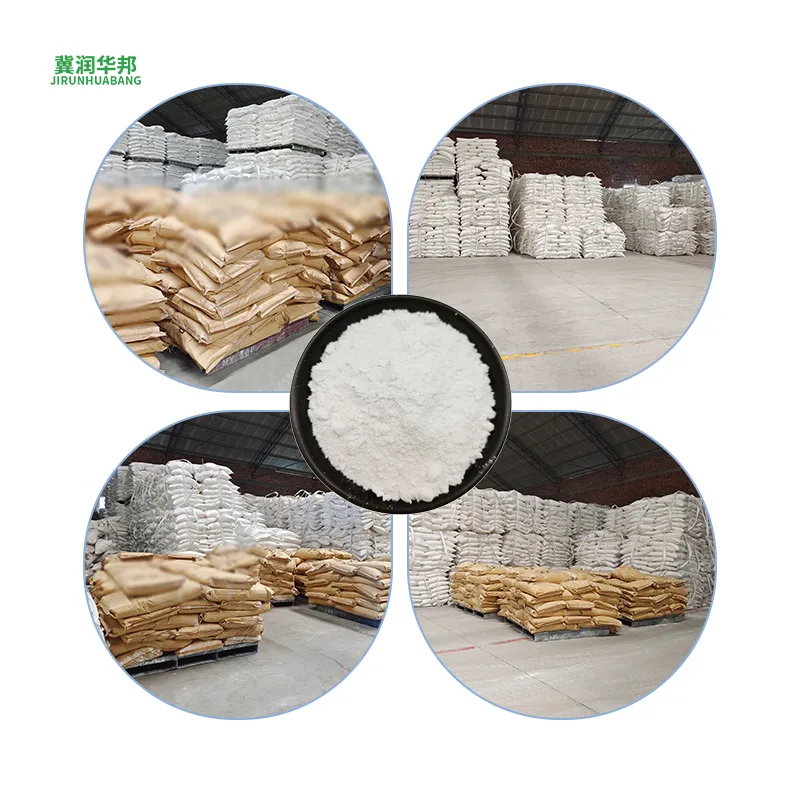

| Package | 5-25kg/bag,customized package |

| MOQ | 1kg |