Polypropylene Fiber: The Ultimate Synthetic Solution for Modern Industry

Quay lại danh sách

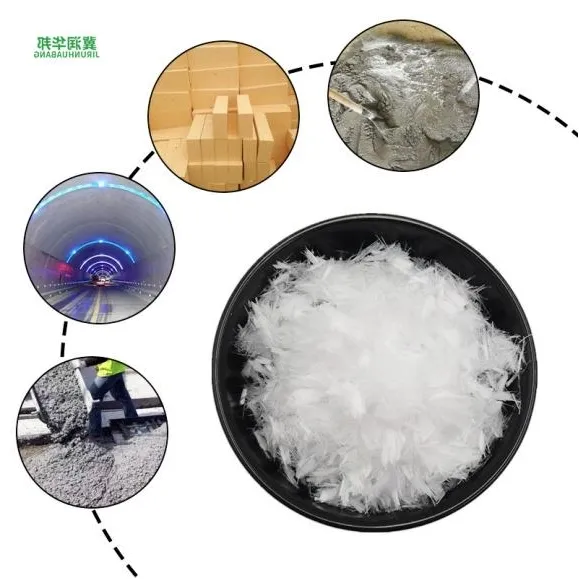

Looking for a durable, cost-effective material that revolutionizes multiple industries? Polypropylene fiber (PP fiber) delivers unmatched performance across countless applications. As China's premier synthetic fiber, this versatile material offers exceptional strength, moisture resistance, and chemical stability. Whether you need fibre polypropylene for construction reinforcement, textile manufacturing, or filtration systems, our premium-grade products meet the highest industry standards. Keep reading to learn why professionals worldwide are switching to this game-changing synthetic fiber.

What Is Polypropylene Fiber?

What is polypropylene exactly? It's a thermoplastic polymer transformed into incredibly strong, lightweight fibers through advanced spinning processes. Unlike natural fibers, sợi polypropylene boasts superior resistance to moisture, chemicals, and abrasion while maintaining remarkable flexibility. These synthetic fibers won't rot, mildew, or degrade in harsh environments, making them perfect for outdoor and industrial applications. The secret lies in their molecular structure - the isotactic arrangement of propylene monomers creates fibers with exceptional durability and performance characteristics that natural materials simply can't match.

Key Benefits of Polypropylene Fiber

Why choose sợi polypropylene over traditional materials? First, its unbeatable strength-to-weight ratio allows for lighter products without sacrificing durability. Second, fibre polypropylene resists most acids, alkalis, and organic solvents, outperforming many metal alternatives in corrosive environments. Third, as one of the lightest commercial fibers (floats on water!), it reduces transportation costs significantly. Fourth, its moisture resistance prevents bacterial growth and maintains integrity in wet conditions. Finally, what is polypropylene's most appealing feature? Its cost-effectiveness - delivering premium performance at a fraction of the price of specialty fibers.

Industrial Applications of Polypropylene Fibre

The uses for sợi polypropylene span dozens of sectors. Construction teams mix it into concrete to prevent cracking and improve impact resistance. Automotive manufacturers incorporate fibre polypropylene into interior components and insulation materials. Geotextile engineers use it for erosion control fabrics that withstand extreme weather conditions. Even the medical field utilizes sterile sợi polypropylene for disposable protective gear. Other applications include: agricultural fabrics, filtration systems, marine ropes, carpet backing, and packaging materials. With such diverse uses, it's no wonder what is polypropylene has become a hot topic across manufacturing industries.

Choosing Quality Polypropylene Fiber

Not all sợi polypropylene products perform equally. Key specifications include denier (fiber thickness), tensile strength, and UV stabilization. Construction-grade fibre polypropylene requires different properties than textile applications. We conduct rigorous quality control on every batch, testing for: consistent diameter, elongation at break, and thermal stability. Whether you need monofilament for filtration or staple fibers for concrete reinforcement, our sợi polypropylene comes with technical documentation guaranteeing it meets your exact requirements.

Polypropylene Fiber FAQs

How does polypropylene fibre compare to nylon?

While both are synthetics, sợi polypropylene offers better moisture resistance and chemical stability at lower cost, though nylon has higher temperature tolerance.

Can polypropylene fiber be recycled?

Yes! One of what is polypropylene's eco-friendly advantages is its excellent recyclability, making it popular for sustainable manufacturing.

Is fibre polypropylene safe for medical use?

Absolutely. Medical-grade sợi polypropylene is non-toxic, hypoallergenic, and widely used in surgical masks, gowns, and other disposable medical textiles.

Why use polypropylene fiber in concrete?

Polypropylene fibre reinforcement reduces cracking by up to 90% and improves impact resistance without the corrosion risks of steel rebar.

Where can I get industrial-grade polypropylene fibre?

As leading manufacturers, we supply premium fibre polypropylene for industrial applications with complete technical specifications and bulk availability.