Wollastonite: The High-Performance Mineral for Modern Industry

Quay lại danh sách

When strength, stability, and sustainability matter, khoáng vật wollastonite delivers unparalleled performance. This naturally occurring calcium silicate has become a game-changer across industries, from advanced ceramics to eco-friendly plastics. As leading wollastonite suppliers, we provide high-purity grades that enhance product durability while reducing environmental impact. Discover why forward-thinking manufacturers worldwide are switching to this versatile material for their most demanding applications.

Why Wollastonite Outperforms Conventional Fillers

What makes wollastonite the preferred choice for engineers and formulators? Its unique needle-like structure provides superior reinforcement compared to conventional fillers. The mineral's natural high strength-to-weight ratio enhances mechanical properties in composites without adding unnecessary weight. Unlike many alternatives, khoáng vật wollastonite offers exceptional thermal stability, maintaining performance even in extreme temperature conditions. Its low moisture absorption prevents product degradation in humid environments, while its chemical inertness ensures compatibility with diverse formulations. These qualities combine to create materials that last longer, perform better, and withstand harsher conditions - all from a single natural mineral.

Innovative Wollastonite Uses Across Industries

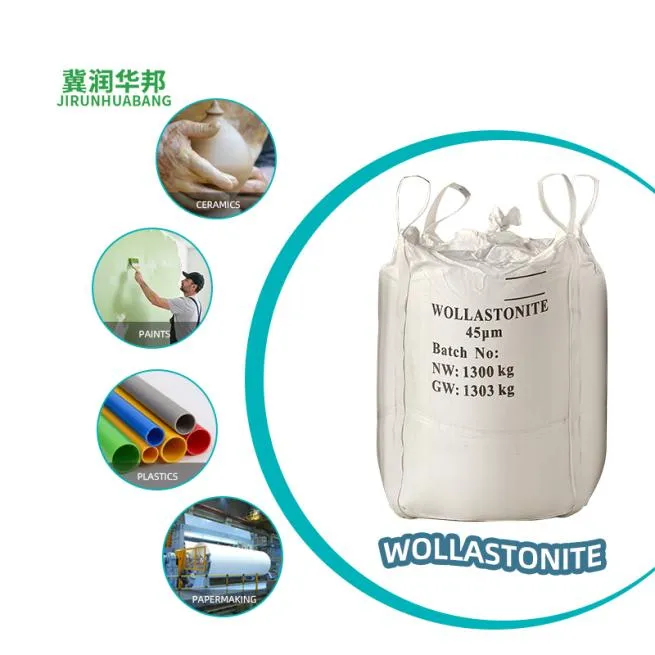

The applications for wollastonite uses continue expanding as industries discover its remarkable benefits. In plastics, it reinforces automotive parts while reducing weight and improving heat resistance. Ceramic manufacturers rely on it to enhance strength and prevent cracking during firing cycles. Paint and coating formulators value its ability to improve durability and weather resistance. Even construction materials benefit from wollastonite's unique properties - it reinforces concrete, improves fire resistance in building materials, and enhances the performance of specialty adhesives. The mineral's natural whiteness and low oil absorption make it particularly valuable for premium applications where appearance and performance must coexist perfectly.

Selecting the Right Wollastonite Grade

Not all khoáng vật wollastonite products perform equally. Key specifications include aspect ratio (length-to-diameter of needles), particle size distribution, and chemical purity. High-aspect ratio wollastonite provides maximum reinforcement for plastic and rubber composites. Fine powder grades work best in ceramics and coatings where smooth finishes are critical. As experienced wollastonite suppliers, we help clients navigate these technical considerations to select the perfect grade for their specific application. Our product range includes everything from standard industrial grades to ultra-refined specialty materials for cutting-edge formulations.

Sustainable Advantages of Wollastonite

In today's eco-conscious market, wollastonite stands out as an environmentally responsible choice. The mineral is naturally non-toxic and requires minimal processing, resulting in a low carbon footprint compared to synthetic alternatives. Many wollastonite uses actually improve sustainability - it reduces material requirements in composites, extends product lifespans, and enables lighter-weight designs that save energy in transportation. Responsible wollastonite suppliers employ mining practices that minimize environmental impact while ensuring long-term resource availability. For manufacturers seeking greener material solutions without compromising performance, this remarkable mineral offers the perfect balance.

Wollastonite FAQs

What makes wollastonite different from other mineral fillers?

Wollastonite's unique needle-like structure provides superior reinforcement compared to conventional fillers, offering better mechanical properties and dimensional stability in finished products.

How does wollastonite improve plastic products?

When used in plastics, khoáng vật wollastonite enhances stiffness, heat resistance, and dimensional stability while reducing weight and material costs - particularly valuable in automotive and industrial applications.

Can wollastonite be used in food-contact applications?

Yes, properly processed wollastonite is FDA-compliant for many food-contact applications, making it ideal for food processing equipment and packaging materials.

Why do paint manufacturers choose wollastonite?

Paint formulators value wollastonite uses for its ability to improve durability, weather resistance, and film integrity while maintaining excellent color consistency and gloss control.

How do I select reliable wollastonite suppliers?

Look for wollastonite suppliers with consistent quality control, comprehensive technical data, and the ability to provide customized particle size distributions for your specific applications.