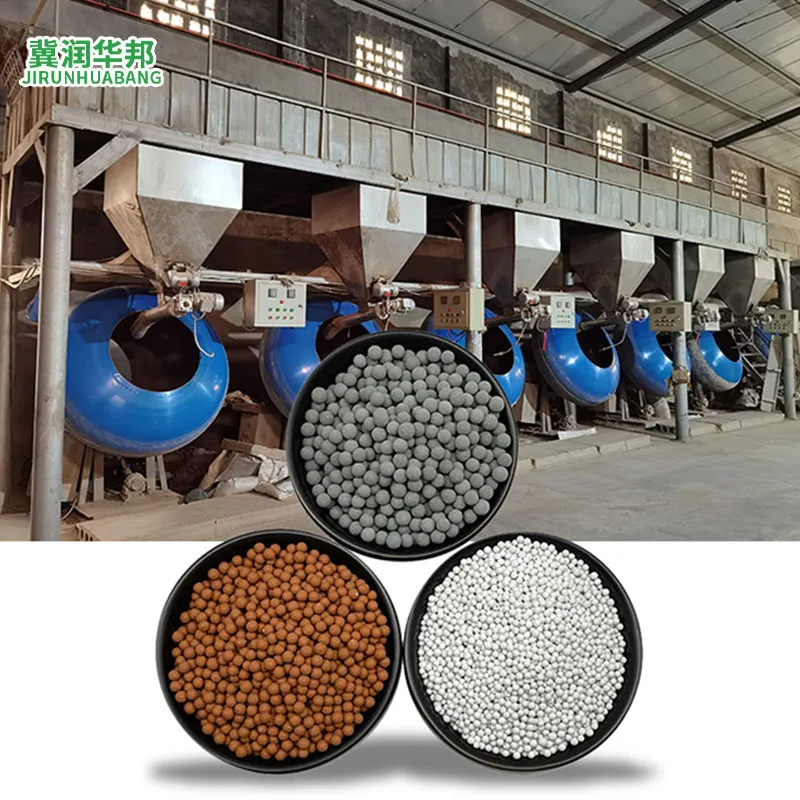

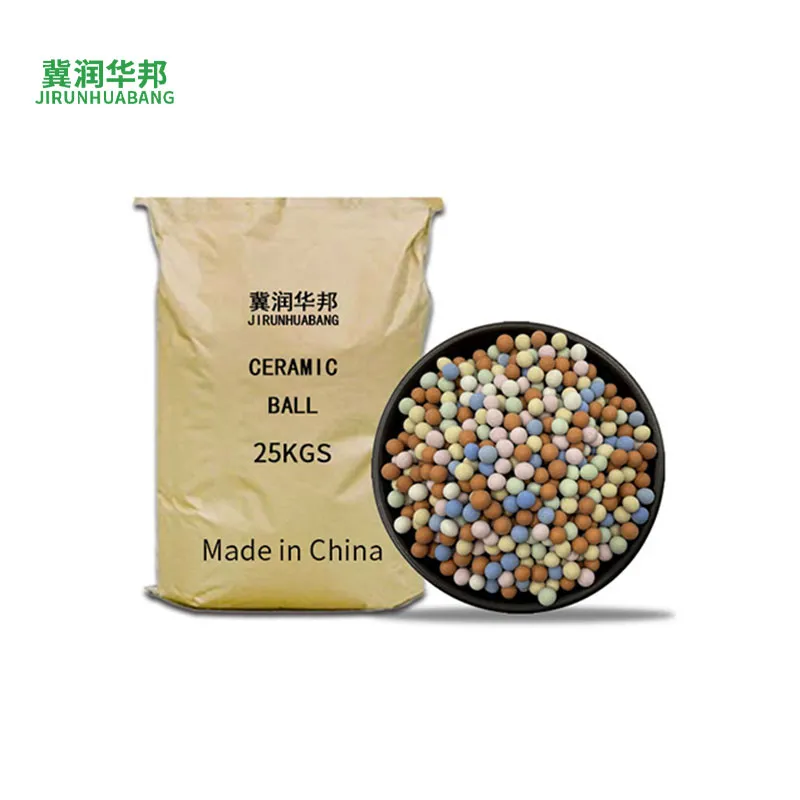

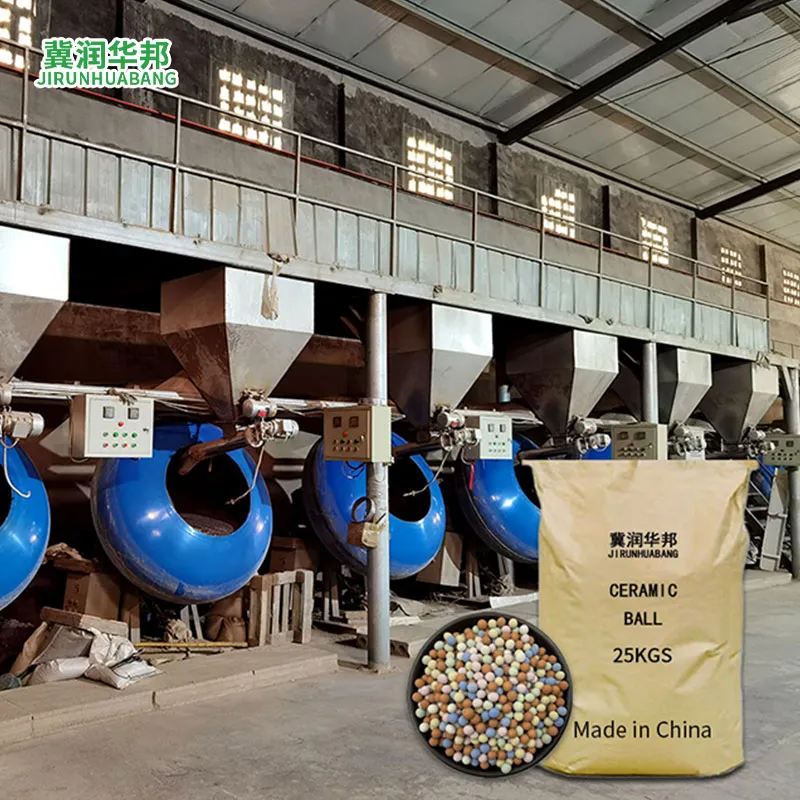

China Factory Price Round-shaped Tourmaline Ceramic Ball for Industrial Grinding Welding Cutting Process Direct Manufacturer

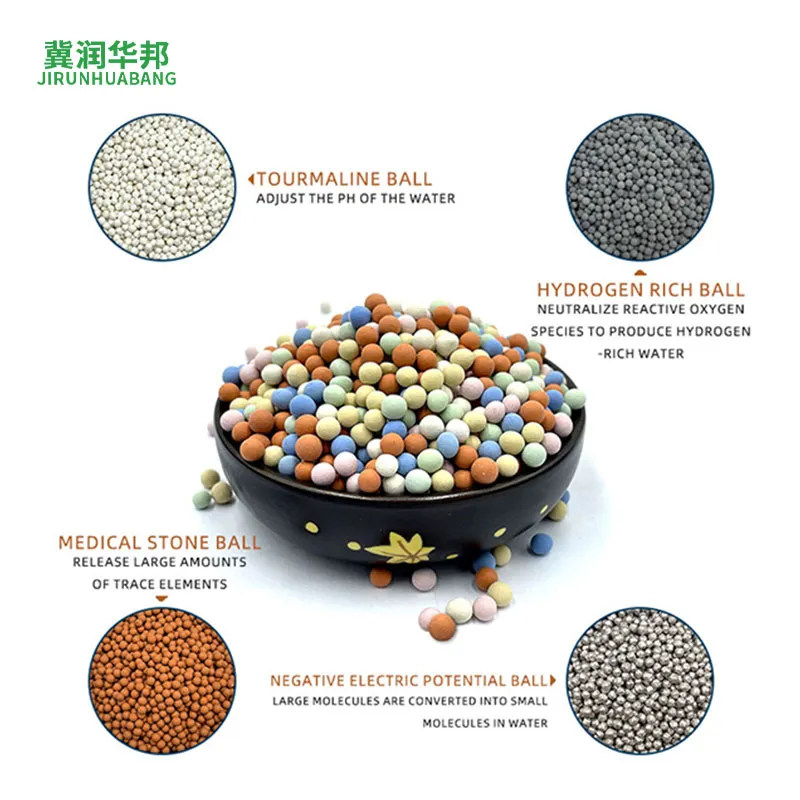

Tourmaline ceramic balls are characterized by their exceptional hardness, wear resistance, and thermal stability. Their round shape further enhances their utility, ensuring smooth and uniform performance in a wide range of industrial settings. When used in grinding processes, these balls provide a more efficient and effective means of material removal, reducing energy consumption and extending the lifespan of grinding equipment.

In welding applications, tourmaline ceramic balls offer unique advantages. Their high thermal conductivity helps to distribute heat evenly across the weld joint, reducing the risk of warping or cracking. Additionally, their non-reactive properties make them ideal for use in welding environments where contamination from reactive materials could compromise the integrity of the weld.

Similarly, in cutting processes, tourmaline ceramic balls contribute to improved precision and reduced wear on cutting tools. Their hardness allows them to withstand the high pressures and temperatures generated during cutting operations, while their smooth surface minimizes friction and heat build-up.

The versatility of round-shaped tourmaline ceramic balls extends beyond these specific applications. Their unique properties make them suitable for use in a variety of other industrial processes, including polishing, mixing, and heat treatment.

In conclusion, the introduction of round-shaped tourmaline ceramic balls represents a significant advancement in industrial materials technology. Their exceptional physical properties and smooth, uniform shape make them an invaluable asset in a wide range of industrial applications, contributing to improved efficiency, performance, and cost-effectiveness.

Product Parameters

| Place of Origin | China |

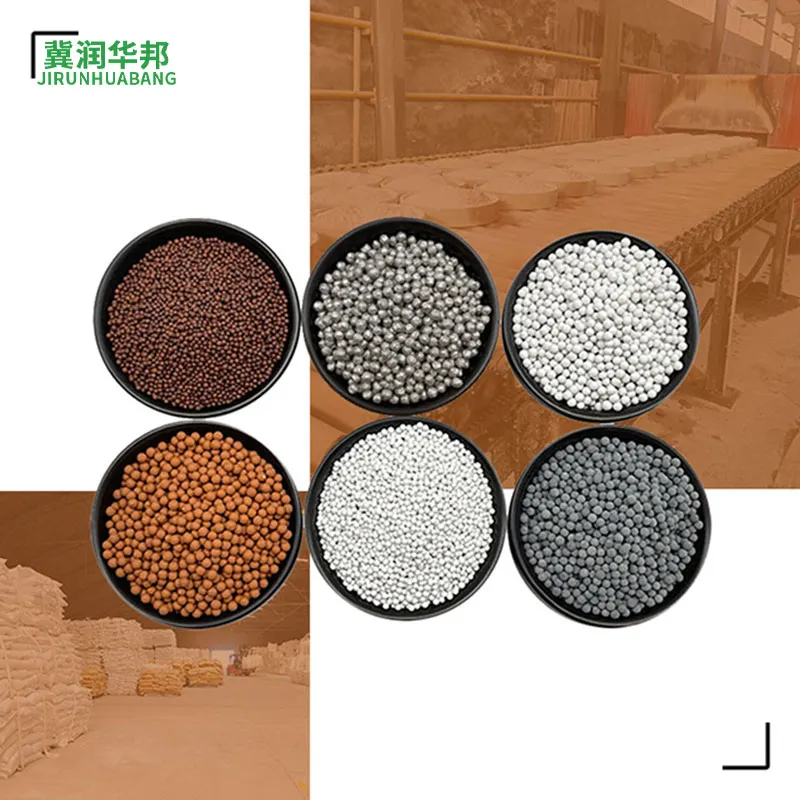

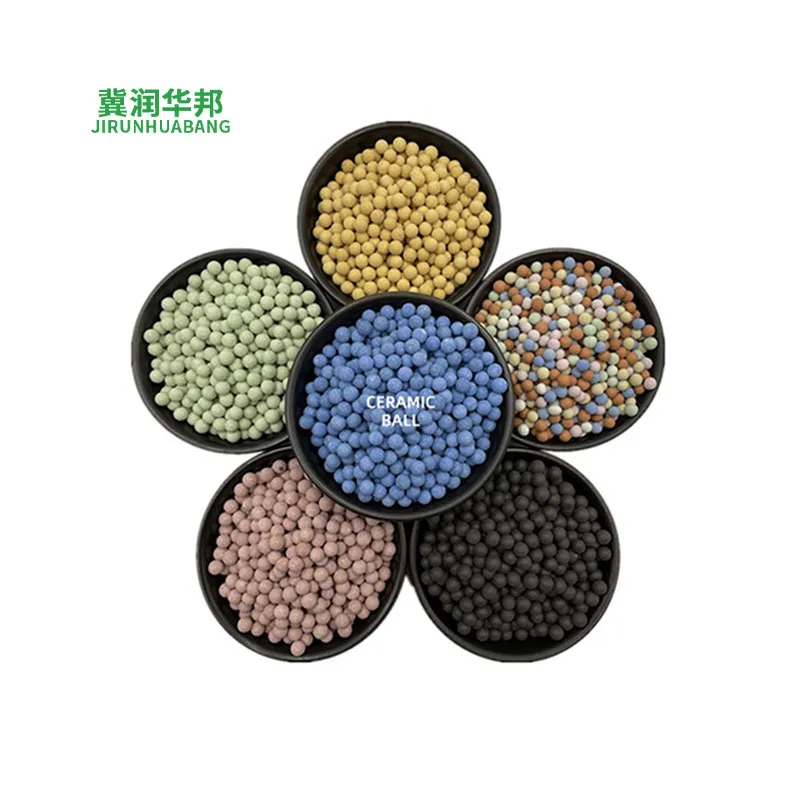

| Color | White/Grey/Yellow/Black and so on |

| Shape | Ball |

| Size | 1mm-2cm |

| Grade | cosmetics grade/industrial Grade/food Grade |

| Package | 5-25kg/bag,customized package |

| MOQ | 1kg |