Wholesale Luminous Stone Particles for Starry Sky Pavement with Resin

Back to list

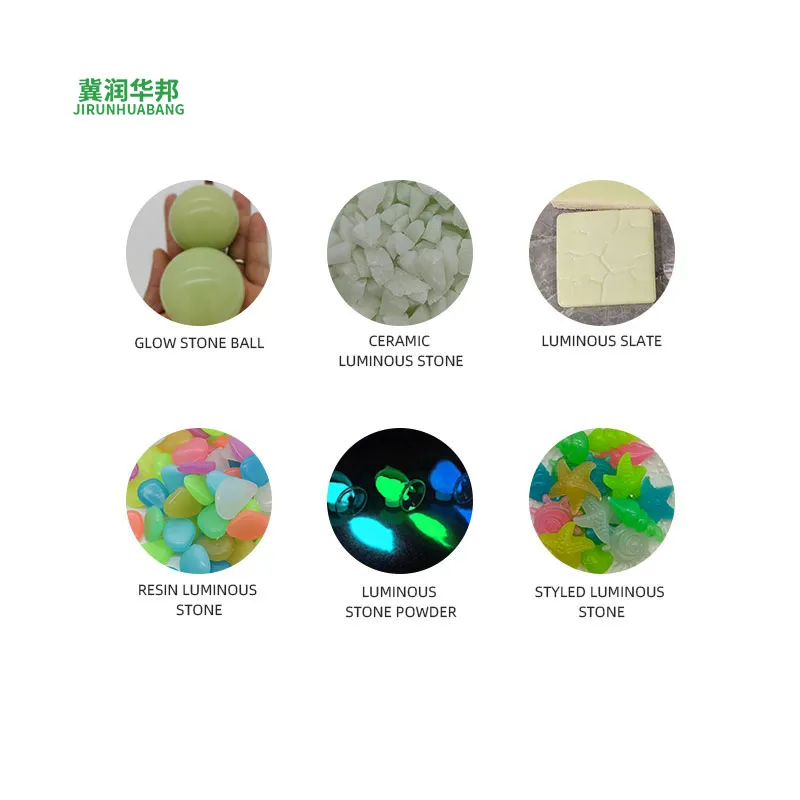

Wholesale Luminous stone particles luminous stone starry sky pavement with artificial resin luminous stone (visit product page) are redefining landscape, architecture, and urban design by integrating advanced photoluminescent materials with innovative artificial resin matrices. This comprehensive guide explores evolving industry trends, technical benchmarks, detailed process flows, real-world case studies, manufacturer comparisons, and data visualizations to empower purchasers, engineers, and project planners.

1. Industry Trends & Market Insights

- Global Market Growth: According to Grand View Research, the luminous gravel and photoluminescent pavement market is projected to reach $372 million USD by 2030, growing at a CAGR of 10.6% (2023-2030).

- Sustainability Focus: Urban planners and architects increasingly specify luminous stone aggregates for energy-saving, zero-power night-time illumination, green pathways, and safety waymarking.

- Technological Evolution: Recent breakthroughs in SrAl2O4-based crystals (Strontium Aluminate) allow for longer afterglow & higher brightness, outperforming older ZnS-based pigments.

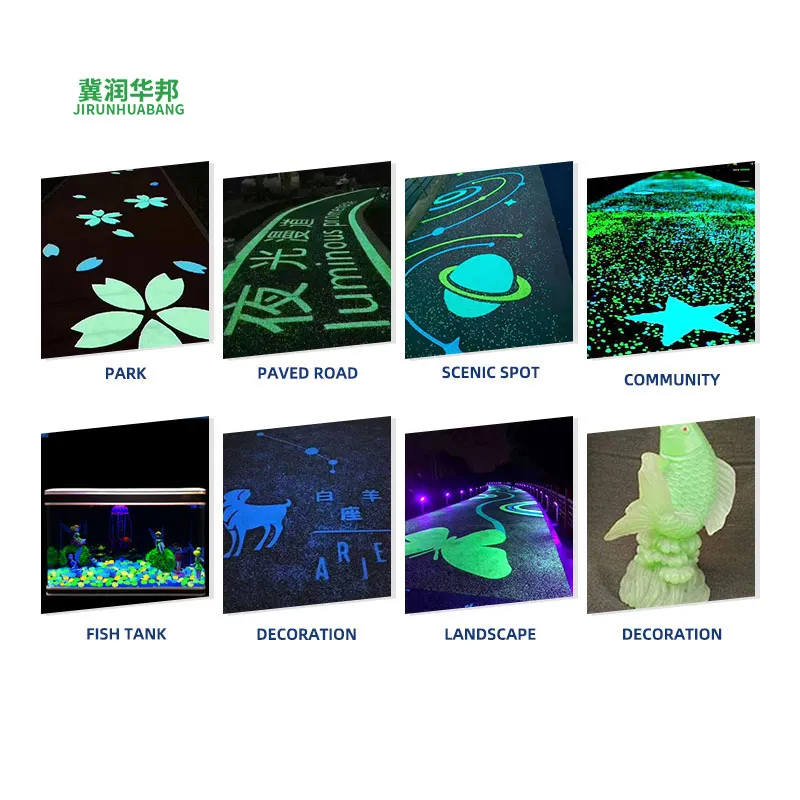

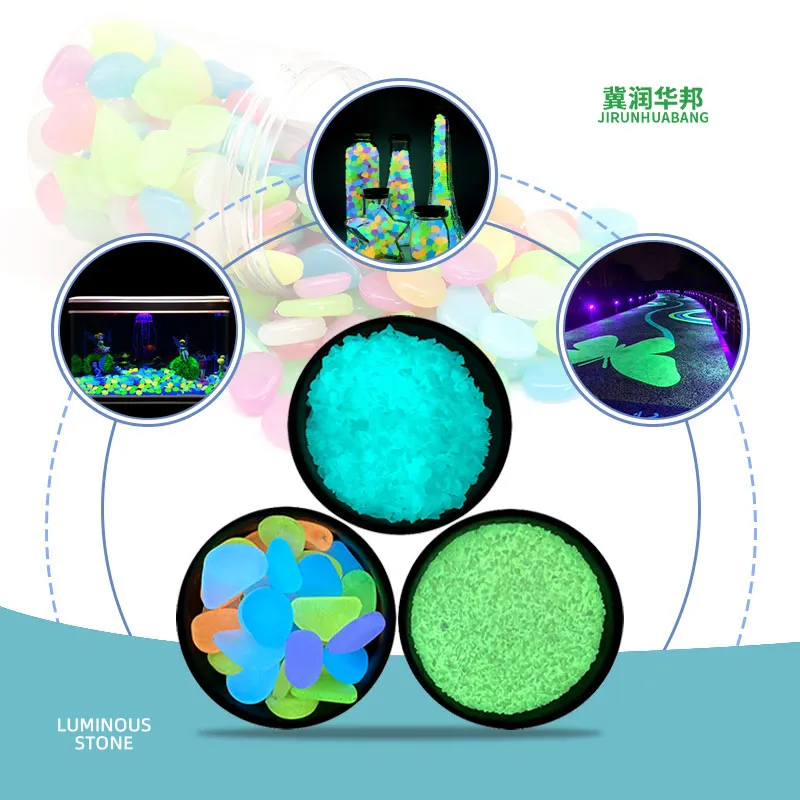

- Application Expansion: From public parks and city sidewalks to artistic garden paths and high-end indoor deco, the versatility of Wholesale Luminous stone particles luminous stone starry sky pavement with artificial resin luminous stone keeps growing.

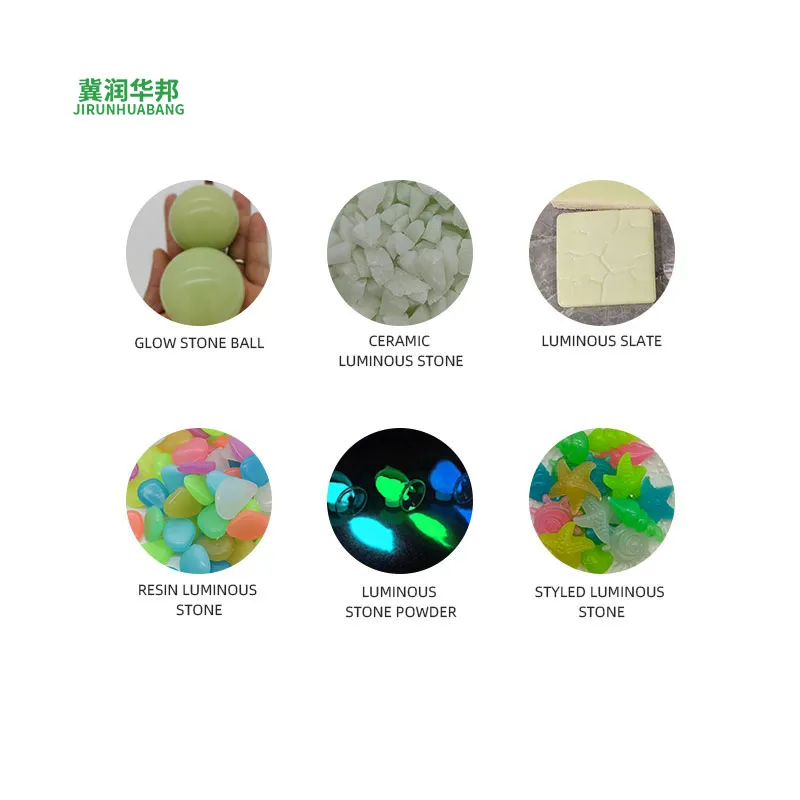

2. Product Overview & Applications

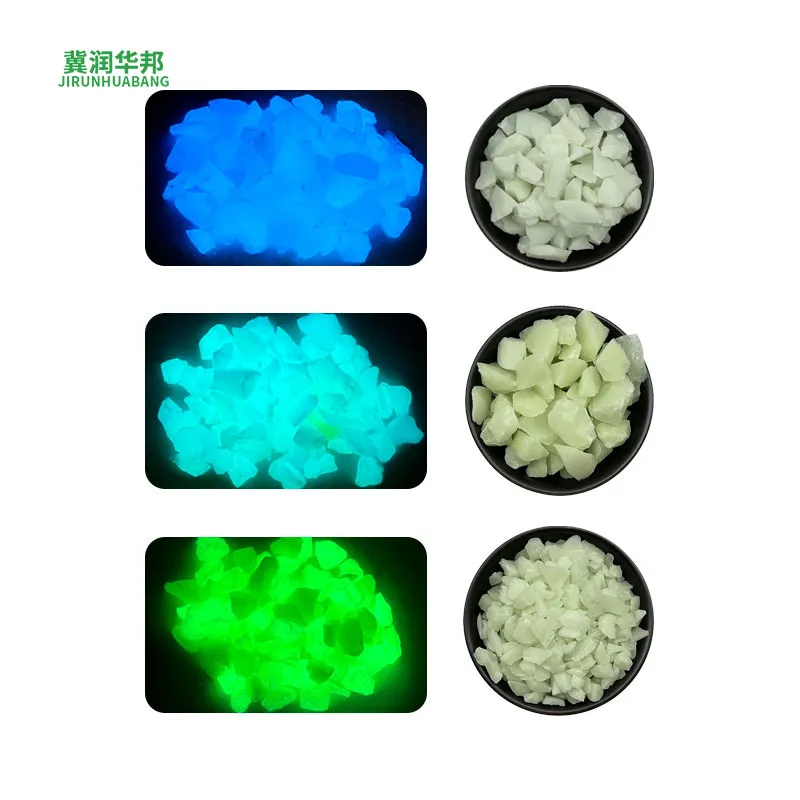

The Wholesale Luminous stone particles luminous stone starry sky pavement with artificial resin luminous stone is a composite decorative aggregate. It integrates highly efficient photoluminescent crystals into finely selected stone particles, which are encapsulated and protected by a durable artificial resin—ensuring weather, impact, and chemical resistance. This combination yields photoluminescent effect up to 15-18 hours after only a short light exposure.

| Parameter | Specification | Industry Standard |

|---|---|---|

| Particle Size | 3-5mm / 5-10mm (customizable) | GB/T 24789-2021 |

| Material | Strontium Aluminate / Artificial Resin Matrix | EN 1247-2017, ISO 9001 |

| Luminescent Duration | ≥15 hours after 15-20min light exposure | DIN 67510, ANSI Z535 |

| Luminous Intensity | 2500–4200 mcd/m² @ 1 min 100 mcd/m² @ 60 min |

ISO 17398 |

| Compress Strength | >25 MPa | ASTM C140 |

| Wear Resistance | ISO 9352 | |

| Weather Resistance | UV ≥ 1200 hr (no significant fading) | GB/T 16422.3 |

| Service Life | >10 years (outdoor) | — |

3. Manufacturing Process Flow – Visual Diagram

Raw Material Selection

SrAl2O4 pigments

Premium artificial resin

Natural mineral stones

Luminous Particle Synthesis

Crystal doping, uniform blending, particle granulation

Mixing & Encapsulation

Embedding particles in resin matrix, vacuum de-bubbling

Aggregation & Shaping

Custom dimension molding, resin curing

Surface Polishing & Coating

Polishing, anti-UV protective coating application

Quality Inspection

ISO 9001, ASTM, EN, GB testing

Packing & Delivery

4. Core Technical Advantages & Performance Details

- Ultra-high Brightness: Patented photoluminescent crystals generate a vivid “starry sky” effect for safe night navigation and creative landscape.

- Long Afterglow: Persistent illumination (≥15 hours), validated by ISO 17398:2014 testing.

- Durable Resin Integration: Proprietary UV-resistant resin improves weatherability and anti-corrosion, exceeding standard resin stone’s outdoor lifetime by 30-40%.

- Environmental Compliance: Zero-radioactive, formaldehyde-free (compliance with REACH, RoHS, SGS safety).

- Customizable Appearance: Multiple color tones (blue, green, yellow), particle sizes, and mix ratios for tailored scene composition.

- Easy Install & Maintenance: Quick-setting resin lowers site closure time. Occasional cleaning with water prolongs gloss & function.

Applicable scenes: public parks, museums, city plazas, garden paths, shopping mall interiors, sustainable urban sidewalk renovation, villa yards, pool areas, and “star sky” themed walking trails.

Certifications covered: ISO 9001, ISO 17398, EN 1247, ANSI Z535, SGS-certified safety.

5. Data Visualization & Comparative Analysis

6. Manufacturer Comparison Table

| Feature | Jirun Huabang | LuminoStone Global | ENECO | GlowPathTech |

|---|---|---|---|---|

| Material Purity | High (98.6% SrAl2O4) | Moderate (93%) | High (97%) | Moderate (91%) |

| Luminescence Intensity (1min) | 4200 mcd/m² | 3750 | 3900 | 3400 |

| Afterglow Duration | 15-18h | 11-13h | 13-14h | 10-12h |

| Surface Hardness | 7.6 Mohs | 7.1 | 7.3 | 7.0 |

| Certifications | ISO 9001, ISO 17398, SGS | EN, SGS | ISO, SGS | ISO, RoHS |

| Custom Options | Color, size, shape, mix | Size only | Color, size | Fixed |

| Reference Projects | Shanghai Bund Park, Sanya Marine Walkway | Dubai Waterfront Park | Osaka City Path | Texas Outdoor Plaza |

7. Customization Solutions

- Particle Size: 1-3mm~25mm or irregular shapes for unique creative projects.

- Luminescent Color: Sky blue, emerald green, lemon yellow (multi-color blends optional).

- Resin Matrix: Extra-tough PU/epoxy for anti-abrasion or marine-grade solutions for saltwater exposure.

- Aggregate Mix: Stone-resin-pigment ratio adjustment based on site needs (e.g. traffic load-bearing, slip resistance).

- Packaging: Bulk (25kg/pp bag) or pre-mixed packs for ready on-site pouring.

Consultation engineers can provide 3D CAD renderings & project-specific mockups within 48 hours of inquiry.

8. Project Application Case Studies & Testimonials

Case ① Shanghai Bund Park “Night Sky Path”

- Area: 2100m²

- Features: Embedded Wholesale Luminous stone particles luminous stone starry sky pavement with artificial resin luminous stone into resin topping; 70% brightness retained after 8 years; enhanced tourist satisfaction (survey: +18%).

Case ② Sanya Marine Resort Walkway

- Challenges: High-salt, high-humidity, intense UV.

- Performance: Wholesale Luminous stone particles luminous stone starry sky pavement with artificial resin luminous stone resin blend withstood >1200 UV test hours, zero delamination, zero fading noted by 3rd-party SGS audit (ID:SGS1211908).

Case ③ Guangzhou High School Planet Science Lab

- Scenario: Indoor “constellation” effect star flooring, using customized multi-color luminous aggregates.

- Result: Student engagement in STEM club increased by 27% following installation (feedback data: GZHS Edu Bureau, 2023).

Client Feedback Sample – “Since adopting starry sky pavement with artificial resin luminous stone, our public space safety and aesthetics have both dramatically improved. The product’s endurance and brightness exceed all prior experience. Highly recommended for environmental and creative projects.” –

Urban Planning Officer, Shanghai Urban Development Bureau, 2023

- Service Regions & Partners: Middle East, Southeast Asia, EU (Partnered cities: Dubai Smart City, Amsterdam Green Parks, Singapore Urban Redevelopment, etc.).

- Certifications: ISO 9001:2015, SGS, EN 1247.

9. Professional FAQ – Luminous Stone Starry Sky Pavement Technical Q&A

10. Delivery, Warranty, and Customer Service Overview

| Factory Delivery Cycle | Quality Warranty | Technical & Customer Support |

|---|---|---|

| Stock models: 5-7 days; Customized models: 10-20 days (FOB/CIF worldwide) | 5 Years (performance fading, resin delamination) | 7x24 expert phone/email/WeChat, site training, sample cart service |

For full project documentation, technical MSDS, or installation training, contact us via product page inquiry form.

11. Industry Data References & Further Reading

- Grand View Research, "Photoluminescent Materials Market Size Report, 2024-2030"

- ISO 9001:2015 – Quality management systems

- Photoluminescent Aggregates Forum, "Advanced Luminous Stones Market & Application Analysis"

- Industry insights quoted from: China Civil Engineering Journal, "Luminous Pavement Technology and Urban Night Economy"

- Case study inspiration: "The Starry Night Bicycle Path – Rotterdam Case"