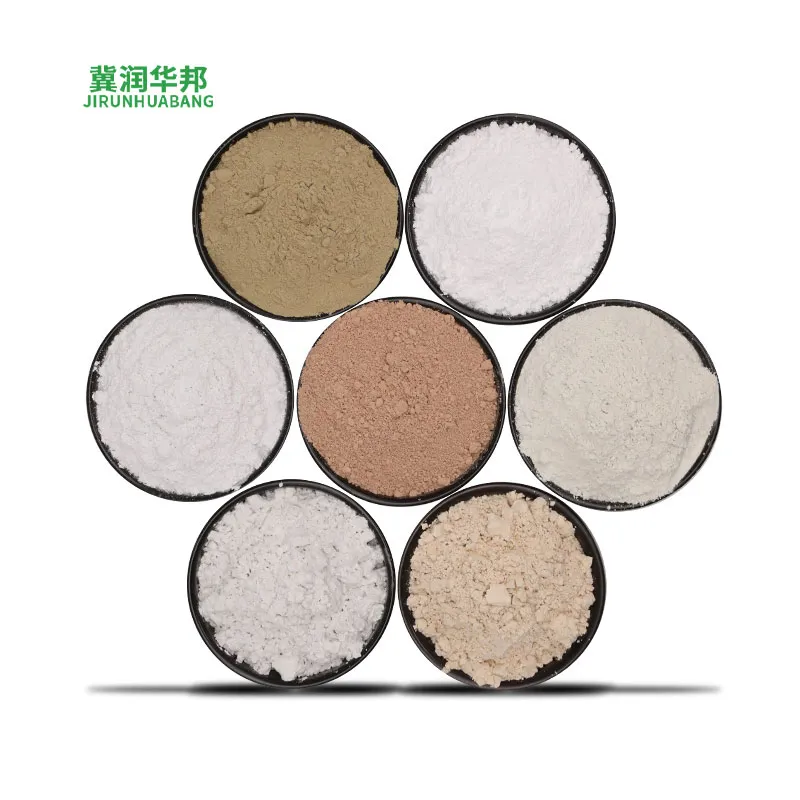

As the global demand for advanced refractory materials and high-performance ceramics rises, manufacturers and engineers are increasingly turning to products offering both technological advancement and verified reliability. The Runhuabang refractory plastic ceramics calcined kaolin paper coating added with water washing kaolin powder stands out with its innovative manufacturing process, stringent testing standards, and wide applicability in sectors like petrochemicals, metallurgy, and special paper production.

Industry Trends: The Shift to High-Purity Calcined Kaolin Solutions

The global calcined kaolin market is projected to surpass $6.7 billion by 2030 (Grand View Research), driven by increasing demand for high-performance refractories, ceramic composites, and specialty paper coatings. Combining calcined kaolin with water-washed kaolin powder boosts performance metrics such as brightness, thermal stability, and resistance to chemical corrosion, all while supporting greener manufacturing.

Technical Overview and Product Specifications

The Runhuabang refractory plastic ceramics calcined kaolin paper coating added with water washing kaolin powder represents a synthesis of high-purity kaolin calcination and advanced purification. Its unique formulation delivers premium whiteness (ISO ≥ 93%), low moisture content (<0.5%) and high Al2O3 content (≥ 44%), enabling improved mechanical and thermal properties.

| Item | Unit | Typical Value | Industry Standard |

|---|---|---|---|

| Brightness (ISO) | % | 94.2 | GB/T 5950-2008 ≥92 |

| Al2O3 content | % | 44.8 | ≥44 |

| SiO2 content | % | 52.7 | ≥50 |

| Fe2O3 content | % | 0.36 | <0.50 |

| Moisture | % | 0.37 | ≤0.5 |

| D50 Particle Size | μm | 1.65 | 1.5 – 2.0 |

| pH Value | - | 6.5 | 6.0 – 7.0 |

| Oil Absorption | g/100g | 44 | ≤45 |

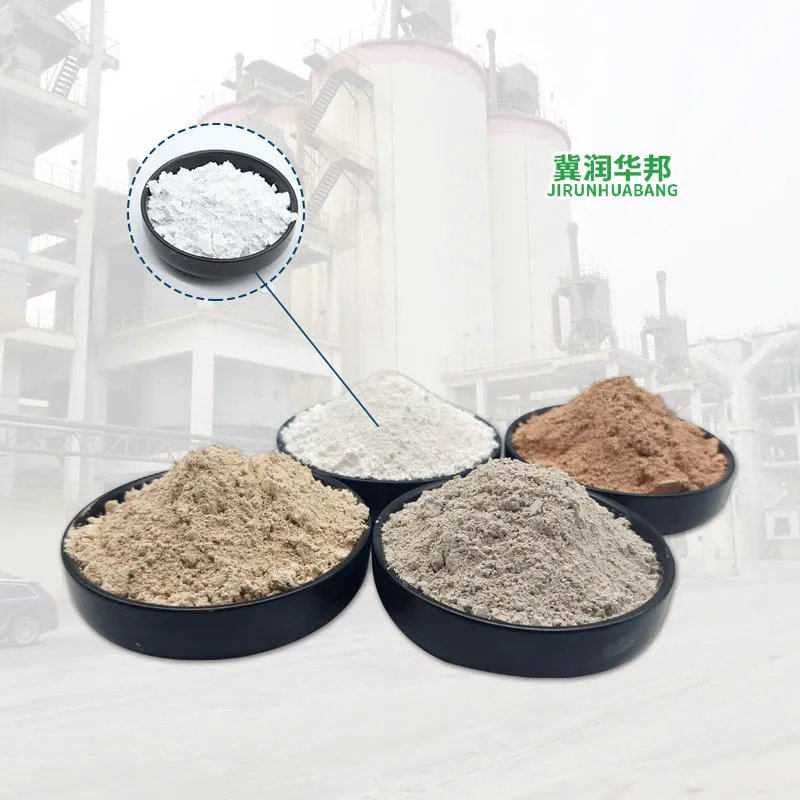

Manufacturing Process: Diagram & Workflow

High-purity natural ore,

iron oxide rejected → Water Washing & Purification

Removes grit, improves whiteness → Calcination

Rotary kiln, 980–1100°C

Transforms crystal structure → CNC Milling & and Classifying

Ensures D50=1.6μm → Quality Detection (ISO)

Brightness, granularity, stability test → Packing & Delivery

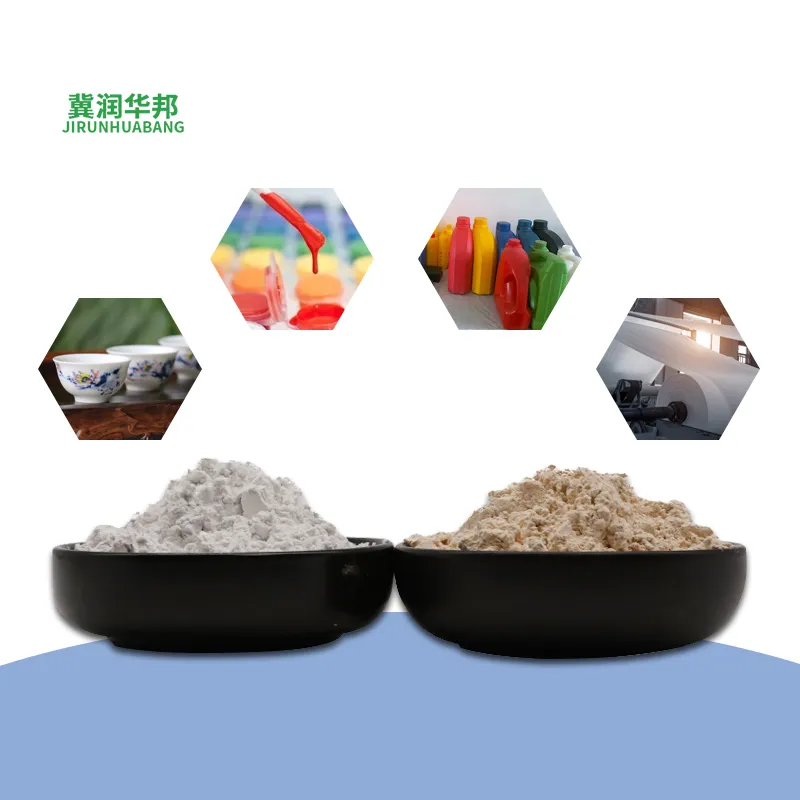

Technical Advantages & Application Scenarios

- Superior Whiteness: Achieves up to 94.2% ISO brightness, surpassing typical paper coating grades, resulting in more vibrant finished products.

- Thermal Stability: Maintains phase composition at up to 1400°C, ideal for refractories and advanced ceramics.

- Low Impurities: Fe2O3 content at 0.36% (vs. common grades of 0.5%+), reduces brownish tint and enhances dielectric properties.

- Enhanced Coating Properties: Fine D50 particle size improves paper smoothness and ink absorption.

- Corrosion & Abrasion Resistance: Feldspar synergies enable use in environments exposed to acids, steam, or heavy metals.

- Eco-Friendly: Utilizes advanced water-washing for ultra-clean product, optimal for green paper & plastics.

Manufacturer Comparison: Performance, Certification & Quality Assurance

| Major Parameter | Runhuabang | Imerys (Global) | LB Group |

|---|---|---|---|

| Brightness (ISO) | 94.2% | 92.8% | 92.0% |

| Al2O3 (%) | 44.8% | 43.5% | 44.0% |

| Particle Size D50 (μm) | 1.65 | 2.1 | 1.92 |

| ISO 9001 Certified | Yes | Yes | Yes |

| Testing Standard | ISO/GB/T 5950-2008 | ISO 787-25 | ISO/GB/T |

| Reference Applications | Ref. Plastics, Ceramics, Coated Paper | Ceramics, Paint, Paper | PVC, Paper, Rubber |

| Custom Solution Avail. | Yes | Limited | Possible |

- Runhuabang adheres to ISO 9001:2015 and ISO 14001:2016 for all kaolin products.

- Partnered with over 230 industrial clients (including Asia Pulp, Shenhua China, CNPC, and regional ceramics leaders).

- 5+ years average project contract span; on-site technical support and after-sales SLA guaranteed.

- Products regularly tested and certified according to ISO/GB/T 5950 and ANSI standards.

Tailored Solutions & Delivery

- Custom grade selection: particle size (D50 from 1.3–2.2μm), brightness control, mineral mix per industry.

- Private label OEM production for global clients.

- Lot-to-lot consistency checked by automated laser particle analyzer.

- Delivery period: Common specs 5–10 business days, custom formulation 2–3 weeks (FCA/FOB available).

- Warranty/Support: 12 months product quality warranty, delayed/replacement arrangement, 24/7 technical support line.

Application Cases & Customer Feedback

- After deploying Runhuabang refractory plastic ceramics calcined kaolin paper coating added with water washing kaolin powder, brightness was improved by 2.3%, print yield up by 4%, with complaints on coating streaking dropping by 37% (internal audit 2023).

- OEM partner replaced previous kaolin supplier; after half-year, mechanical strength of end-products improved by ~7%, scrap rate fell by nearly 2%. Customer satisfaction and repeat orders increased.

- “The consistency and whiteness of Runhuabang’s calcined kaolin helps us maintain our premium brand image. The post-sale technical response is among the best we’ve encountered.” — Senior Engineer, Papermaking Group

- “No other supplier supported such customized grades and fast sample turnaround.” — Operations Director, Ceramics Plant

FAQ: Professional Terms on Material, Specs & Standards

Why Choose Runhuabang refractory plastic ceramics calcined kaolin paper coating added with water washing kaolin powder?

- Consistently higher brightness and chemical purity than main competitors

- Strict adherence to international standards: ISO, ANSI, TAPPI

- Innovative process combining calcination and water-washing for optimal end-properties

- Flexible and responsive technical support and customization

- Proven use cases, industry-backed by referenceable clients

- 12-month product warranty with transparent support commitments

- On-time delivery—tracked and guaranteed

References & Further Reading

- Grand View Research. “Calcined Kaolin Market Size, Report 2023–2030.” https://www.grandviewresearch.com/industry-analysis/calcined-kaolin-market

- ISO/GB/T 5950. “Kaolin and Kaolinitic Clays: Determination of Brightness.” https://www.iso.org/standard/11625.html

- Materials Forum, Vol 46, “Role of Calcined Kaolin in Refractory Ceramics”. https://www.materialsforum.org.au/volume/46/

- TAPPI. “Technical Association of the Pulp and Paper Industry: Kaolin Usage for Paper Coating Guidelines.” https://www.tappi.org/