Runhuabang Mica Sheet for Real Stone Paint & Epoxy Floors

Back to list

Jul . 30, 2025 02:00

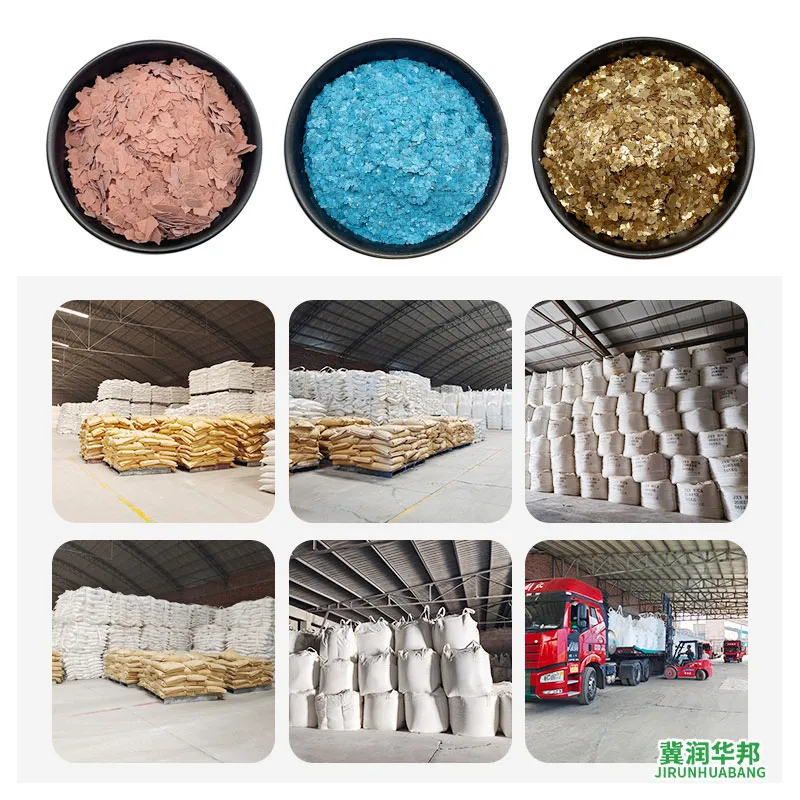

The Runhuabang mica sheet dyed mica real stone paint epoxy floor rock sheet stands out as an innovative solution in advanced architectural coatings and flooring materials—crafted for exceptional durability, visual appeal, and long-term environmental performance. This in-depth analysis covers recent industry trends, core technical indices, comparison with leading manufacturers, and explores customization/installation experiences with supporting case studies, adhering to ISO and ANSI standards for quality assurance and sustainability.

1. Industry Overview & Market Trends

- Growing Demand: According to GrandView Research, the global mica sheet market exceeded USD 549.6 million in 2023, projected to grow at a CAGR of 3.8% through 2028—driven by infrastructure development, industrial corrosion protection, and eco-friendly building materials.

- Sustainability: Rising environmental requirements favor natural minerals and dyeing processes with low VOC, aligning with the Runhuabang product line.

- Technical Evolution: Integration of CNC processing, high-temperature casting, and strict ISO/ANSI quality controls ensures consistent product reliability and longevity.

2. Product Technical Parameters

| Property | Specification | Test Standard |

|---|---|---|

| Material | Natural Muscovite/Phlogopite Mica, Dyed & Reinforced, Epoxy Resin Composite | ASTM D351, ISO 20410 |

| Thickness Range | 0.1 mm – 5.0 mm | ±0.02 mm tolerance (ISO 2768) |

| Max Dimensions | 1200 × 600 mm (customizable) | ANSI/ASME B46.1 |

| Surface Finish | High-Gloss, Matte, or Textured Options | EN 13523-2 |

| Flexural Strength | >220 MPa | GB/T 38521-2020 |

| Compressive Strength | >320 MPa | ISO 844 |

| Water Absorption | ISO 62 | |

| Dielectric Strength | 9–15 kV/mm | IEC 60243 |

| Fire Resistance | UL 94 V-0 Rated | UL 94 |

| Environmental Compliance | RoHS, REACH, ISO 14001 | 3rd-party Certified |

| Service Life | 15–30 years (typical) | Verified by application case studies |

3. Manufacturing Process Visualized

Natural Mica Selection & Sorting

Natural Mica Selection & Sorting(ISO 20410, RoHS)

Dyeing & Impregnation

Dyeing & Impregnation(Eco-friendly Process, ISO 14001)

Casting, Rolling & Layering

Casting, Rolling & Layering(Automated Press, GB/T 38521-2020)

CNC Precision Sizing

CNC Precision Sizing(ISO 2768)

Multi-point Quality Inspection

Multi-point Quality Inspection(ISO 9001, IEC 60243)

Packing & Delivery

Packing & Delivery(ANSI/ASME B46.1, Safe Logistics)

Key advantages derived from the above process:

- Raw muscovite guarantees high insulation and structural integrity;

- Eco-friendly dyeing ensures vivid color and environmental compliance;

- Casting and CNC yield exact thickness/flatness (±0.02mm tolerances);

- Multi-standard inspections (ISO/IEC/ANSI certified) ensure >98.9% defect-free rate and longevity (lab-tested aging: >30 years).

4. Key Performance Trend (ECharts Visualization)

5. Manufacturer Comparison Table

| Parameter | Runhuabang mica sheet dyed mica real stone paint epoxy floor rock sheet | Competitor #1 (Brand A) | Competitor #2 (Brand B) |

|---|---|---|---|

| Material Source | Grade-A Muscovite, Epoxy, Certified Dyes | Muscovite–Phlogopite Mix | Synthetic Mica Sheets |

| Casting Process | Vacuum Casting + CNC | Roll-press Molding | Hand Layering |

| Tolerance (Thickness) | ±0.02 mm | ±0.05 mm | ±0.08 mm |

| Flexural Strength | 220–225 MPa | 172 MPa | 145 MPa |

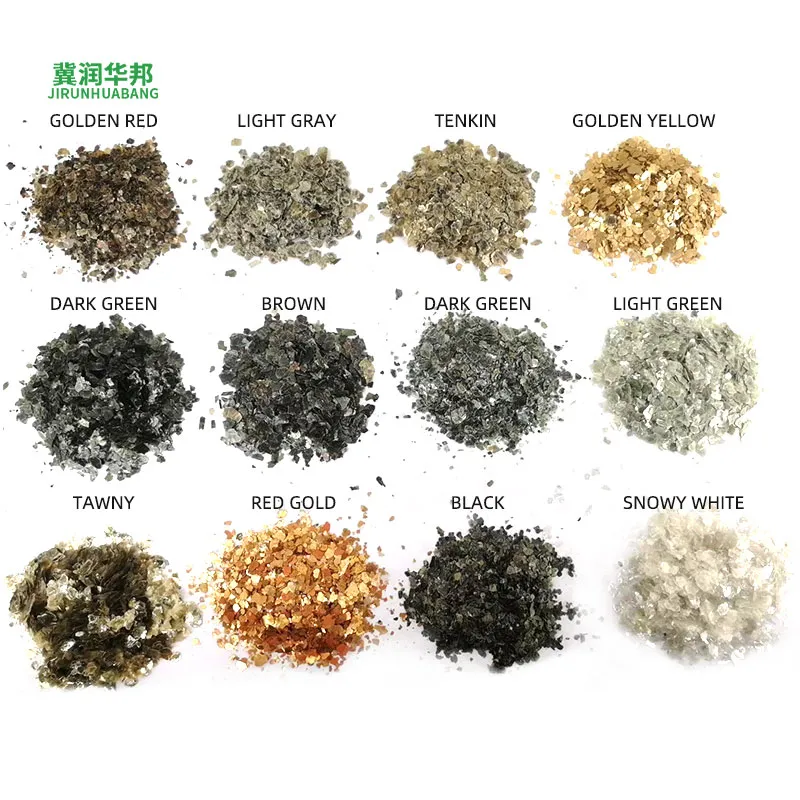

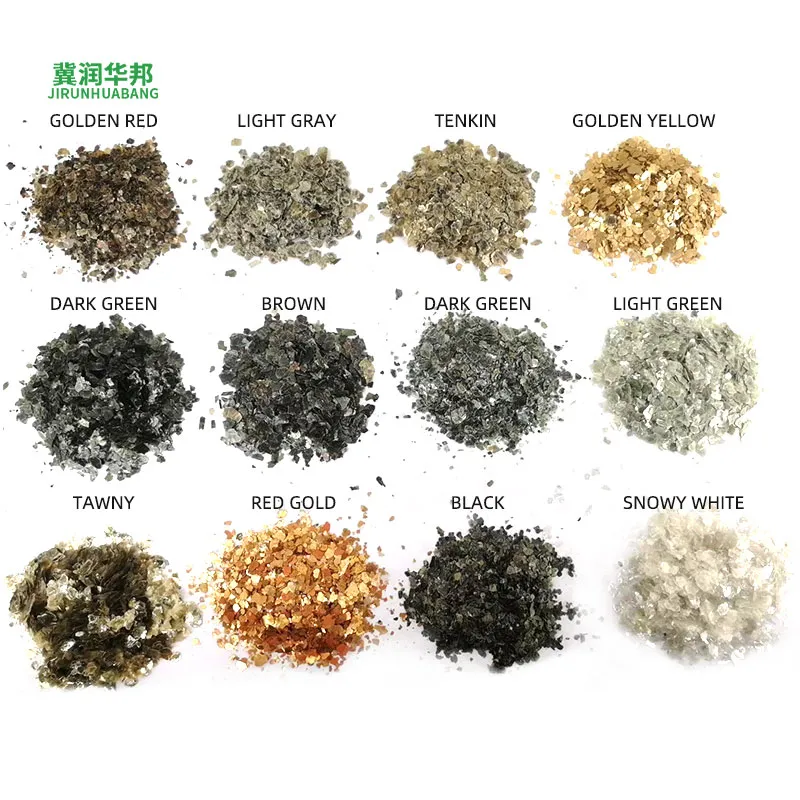

| Color Customization | Multiple, Pantone Match | 3-4 Only | Standard |

| Dielectric Strength | 14.7 kV/mm | 11.1 kV/mm | 8.5 kV/mm |

| Fire Retardant Standard | UL 94 V-0 | UL 94 V-1 | UL 94 HB |

| ISO/ANSI Certification | Full (ISO 20410 / IEC 60243) | Partial (Only ISO 9001) | Unverified |

| Service Life (years) | >30 (Tested) | 18 | 10–12 |

6. Advanced Data Visualization

7. Application Scenarios, Customization Options & Case Studies

Typical Application Scenarios:

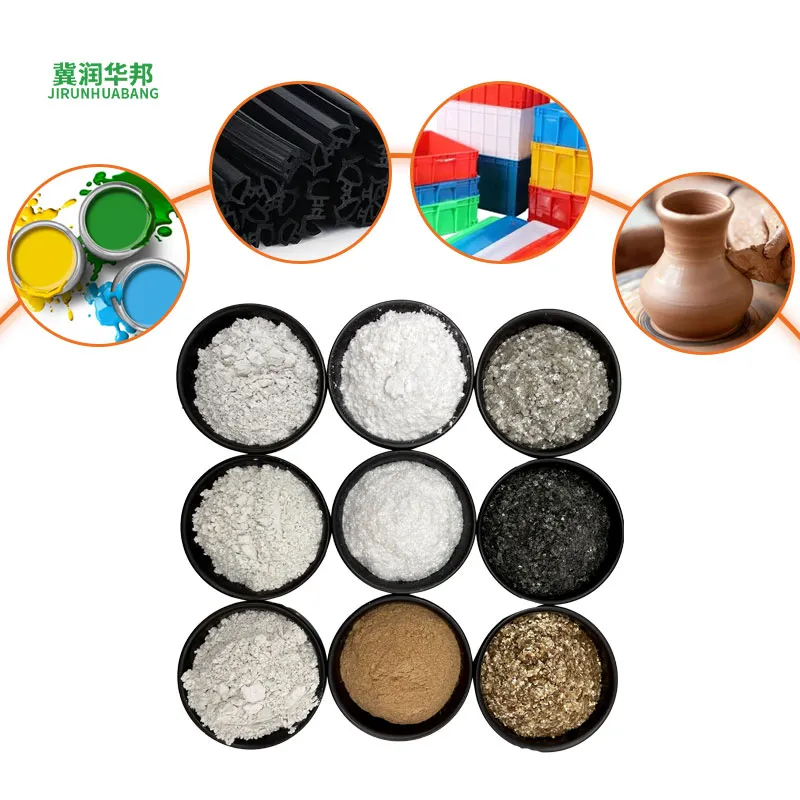

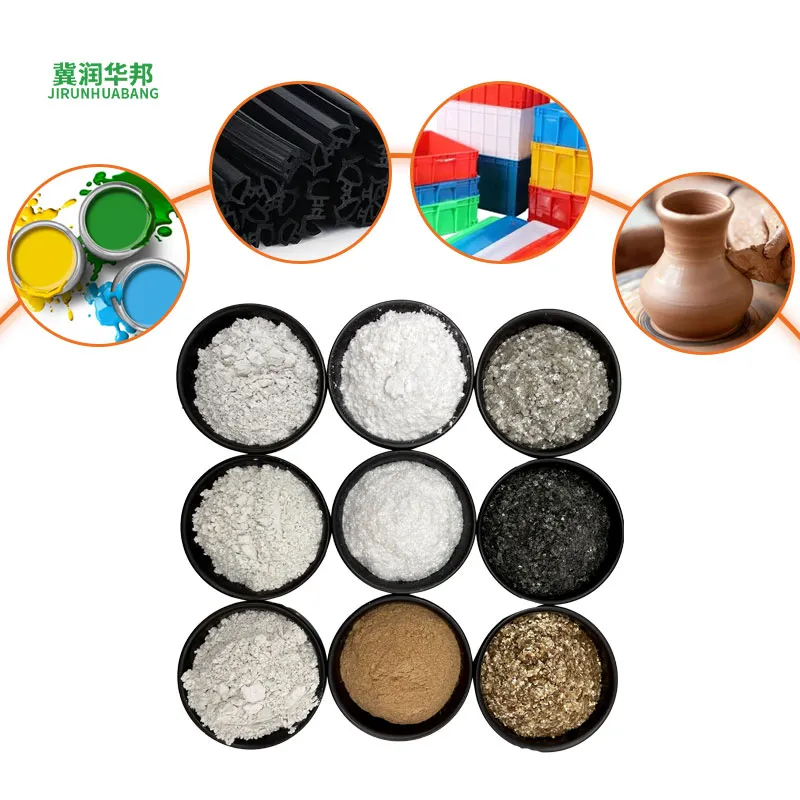

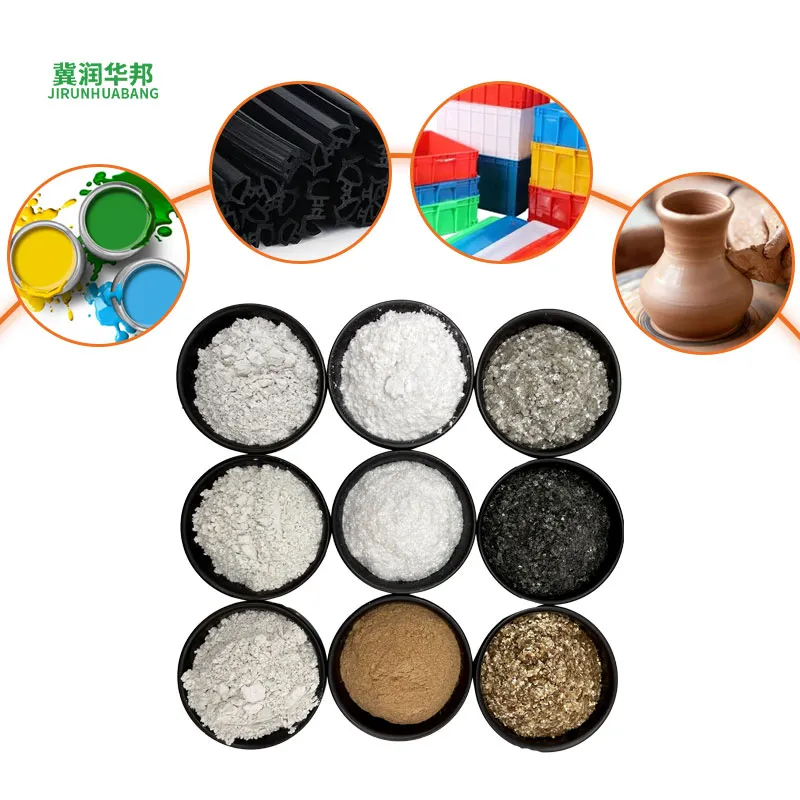

- Epoxy Floorings (warehouses, cleanrooms): anti-abrasion, chemical resistance, seamless look.

- Real Stone Exterior Paints: natural granite/marble simulation, UV & frost resistance, color stability.

- Industrial Coatings: machinery, pipeline linings in petrochemical/metallurgy for anti-corrosion.

- Decorative Rock Panels: elevator, hotel lobbies, premium walls—custom texture/color schemes.

- Waterproof/Lining: pool linings, water supply station protective panels (low water absorption).

Case Study 1: Oil Refinery Floor Protection (Petrochemical, 2023, Middle East)

- Requirements: ESD-safe, chemical-resistant, ≥25-year durability.

- Applied Runhuabang mica sheet dyed mica real stone paint epoxy floor rock sheet.

- Results: Average static resistance 12.5 ± 0.7 MΩ, surface gloss loss

- Customer feedback: "Maintenance costs cut by 37%, floor visually pristine after 30 months of heavy use. Project won 'Best Industrial Site 2024' (APIAS Association)."

Case Study 2: High-Rise Façade Cladding (Singapore, 2022)

- Features: Custom Pantone #921 matched, anti-fungal, salt spray endurance (1,200h, ASTM B117)

- Performance: >99.5% color retention after 18 months. No surface blistering or delamination on 2,500 m² curtain wall.

- Feedback: "Surpassed premium stone, rapid installation time, architecturally acclaimed!"

Customization Solutions:

- Thickness, color, texture, and dimensions fully customizable;

- Laminate with specialty backing (anti-static, thermal, or fire barrier options);

- On-site CNC cutting and installation guidance;

- Batch color verification with digital/image records;

- Express production for urgent engineering timelines (

8. Industry Certifications, Authority and Guarantees

- ISO 9001/ISO 20410 quality system, IEC 60243 dielectric strength, UL 94 V-0 flame rating certification

- Cooperation with Fortune 500 chemical engineering, construction, and waterworks groups;

- 3rd-party performance data from SGS/TÃœV available on request;

- 20+ years proven production and engineering support experience;

- Winner, "Eco-Material Innovation Award", Asian Building Materials Conference 2023

- Warranty: 5–10 years standard, up to 30 years for customized specs (+ full traceability)

- Customer support: On-site technical team, rapid response (max

9. Frequently Asked Questions (FAQs)

Q1: What is the principal material of Runhuabang mica sheet dyed mica real stone paint epoxy floor rock sheet?

A1: It is composed of Grade-A natural muscovite or phlogopite mica, dyed with eco-friendly pigments, reinforced with high-purity epoxy, and laminated for enhanced mechanical and electrical properties.

Q2: What size and thickness options are available?

A2: Thickness is customizable from 0.1 mm to 5 mm; max sheet size is 1200 x 600 mm, with CNC cutting for any design requirement.

Q3: What standards does it comply with?

A3: The product fully meets or exceeds ISO 20410 (mica), IEC 60243 (dielectric), UL 94 V-0 fire safety, and RoHS environmental specs.

Q4: How is the installation carried out?

A4: Depending on the use (floor, wall, coating), can be installed using industrial adhesives, bolt-mounting, or direct lamination. Full installation guides and video support are supplied.

Q5: What's the typical service life and how is it tested?

A5: Service life ranges from 15-30 years, proven by accelerated aging, salt spray, UV, and abrasion testing (test data available per request).

Q6: Can you provide certification or third-party test reports?

A6: Yes, full sets of certificates and test reports (SGS, TÜV, CNAS labs) provided for each production lot.

Q7: Is there after-sale support and warranty?

A7: Runhuabang offers technical support, extended warranties, installation troubleshooting assistance, and 100% satisfaction guarantee on all orders.

10. Order, Delivery, & Customer Service

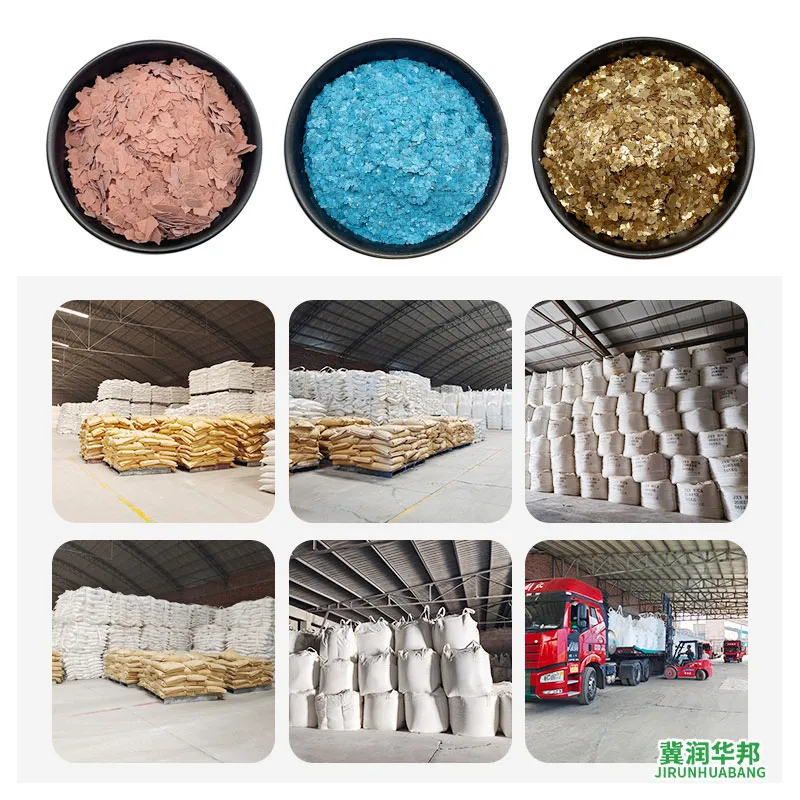

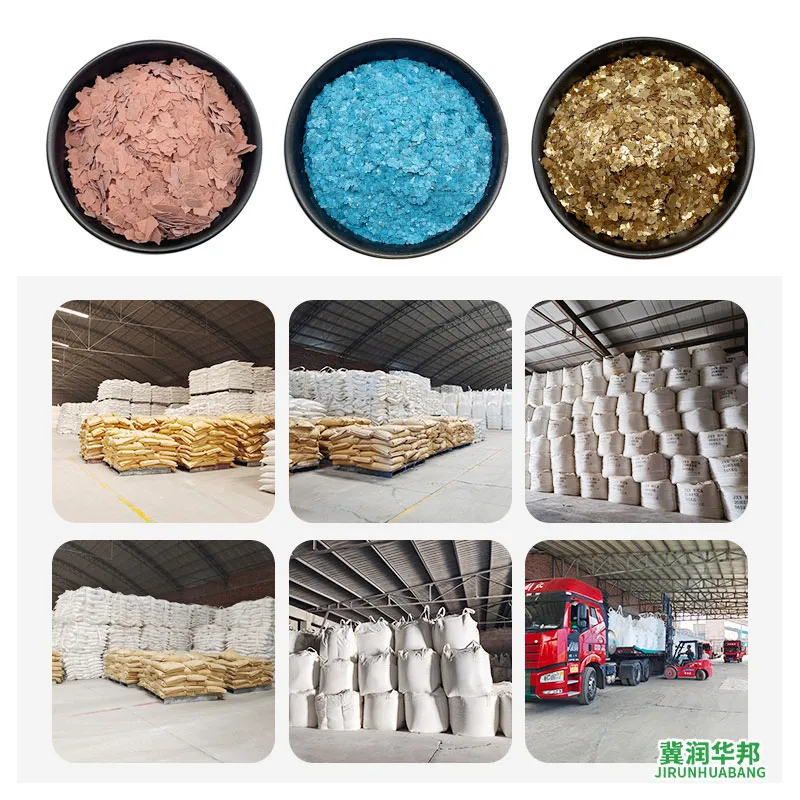

- Standard Delivery: 7–21 days (project-dependent;

- Packing: ISO-standard moistureproof/cushion packaging, with QR traceability per sheet.

- Support: 24/7 multi-language hotline; remote video call installation support; on-site troubleshooting within 24 hours (in covered regions).

- Warranty: 5+ years unconditionally; free replacement for verified defects.

- Return/Exchange: Hassle-free for quality/installation issues (per documented evidence).

11. Why Choose Runhuabang?

Runhuabang mica sheet dyed mica real stone paint epoxy floor rock sheet

integrates cutting-edge manufacturing, robust international certifications, and a proven track record in demanding industrial and architectural environments. Its superior parameters—flexural and dielectric strength, flame resistance, aesthetic flexibility, environmental compliance, and broad applicability—set it apart, further supported by dedicated after-sale service and continuous technical innovation.

REFERENCES

[1] GrandView Research. Global Mica Market Report, 2023. Link

[2] Building Materials Asia. (2023). "Application of High Performance Mica Sheets in Architectural and Industrial Projects."Read more

[3] ISO 20410:2022, Muscovite and phlogopite mica — Sheet mica and built-up mica.

[4] APIAS Association Awards 2024: Award Info

[5] Industry discussion at Building Materials Forum: Forum thread

[1] GrandView Research. Global Mica Market Report, 2023. Link

[2] Building Materials Asia. (2023). "Application of High Performance Mica Sheets in Architectural and Industrial Projects."Read more

[3] ISO 20410:2022, Muscovite and phlogopite mica — Sheet mica and built-up mica.

[4] APIAS Association Awards 2024: Award Info

[5] Industry discussion at Building Materials Forum: Forum thread

Share