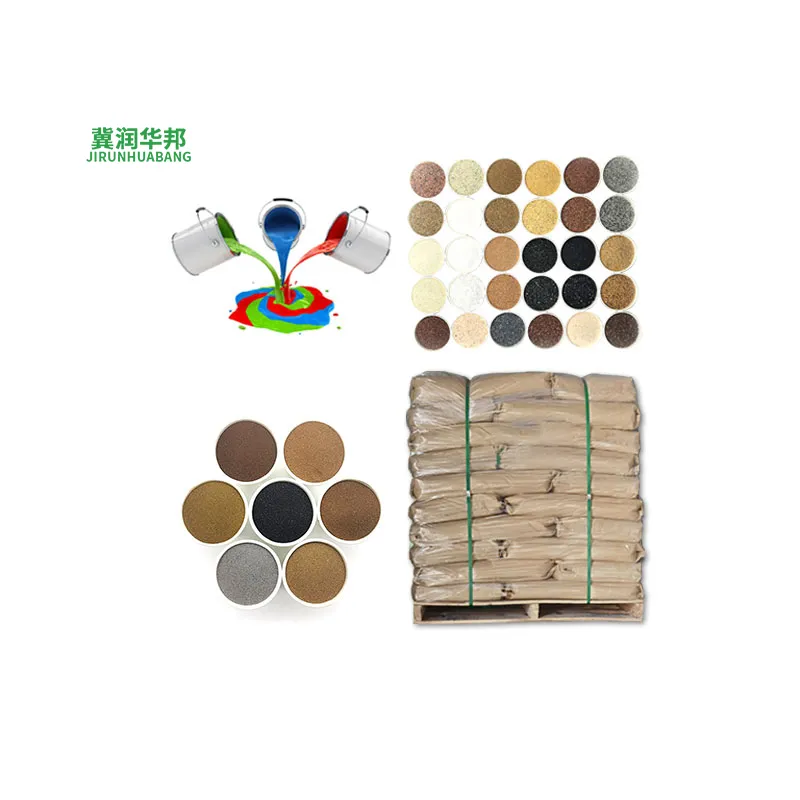

Runhuabang Interior and Exterior Paint - Natural Color Sand, Lasting Beauty

Back to list

Rapid advancements within architectural coatings and industrial surface protection have led to increased demand for eco-friendly, functional, and aesthetically-advanced paint products. According to the Grand View Research 2024 Report, the global decorative coatings market is projected to grow at a CAGR of 5.3% (2023-2030), with mineral-based, weather-resistant, and sustainable paints outpacing average sector growth.

Solutions like Runhuabang Interior and exterior paint with natural color sand high temperature sintering color variety lasting beautiful are gaining momentum due to:

- Natural color sand—delivering authentic textures and sustainable appeal.

- High temperature sintering—maximizing adhesion, hardness, and color durability.

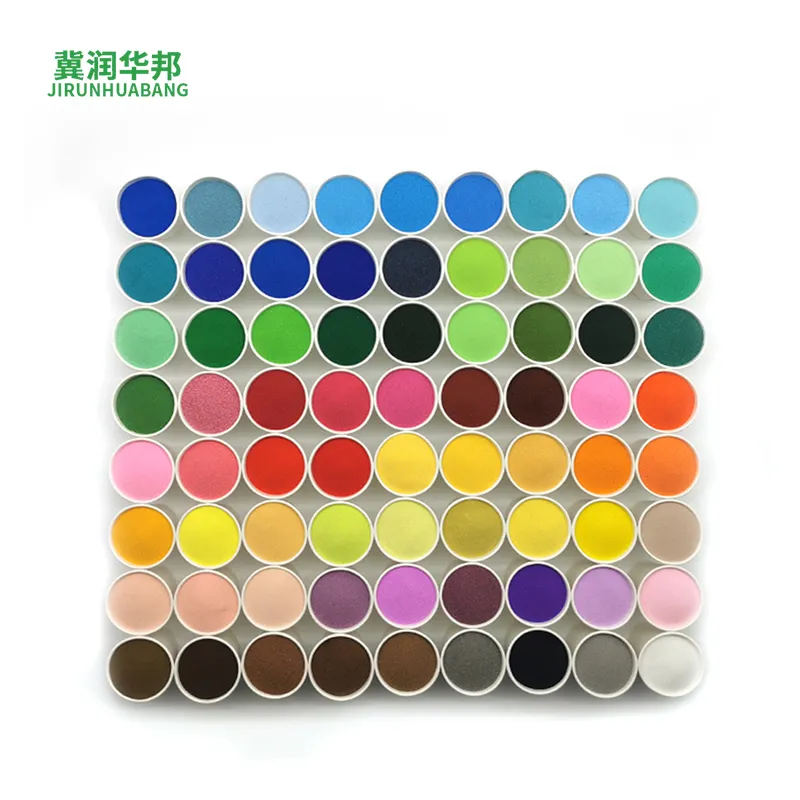

- Multi-color options & lasting beauty—enabling custom architecture, modern decor, and long-term vibrance.

| Parameter | Runhuabang Paint | Conventional Paint | Test Standard |

|---|---|---|---|

| Color Options | 35+ natural sand colors | 8–15 synthetic colors | ISO 11664 (Colorimetry) |

| Substrate Adhesion | ≥ 1.5 MPa (Excellent) | 0.8–1.2 MPa | GB/T 5210-2006 |

| Fineness of Grind | <40μm | 50–70μm | ISO 1524 |

| Surface Hardness | 2–3H (High) | 1–2H | ASTM D3363 |

| Weather Resistance | >3,500h QUV® (No discoloration/cracking) | ~2,100h (Fading visible) | ISO 11507 |

| VOC Content | <50g/L | 120–180g/L | EU 2010/75/EU |

| Thermal Tolerance | -25°C to +180°C | -10°C to +95°C | GB/T 1735 |

| Service Life | 15–20 yrs (exterior) | 6–9 yrs | Corporate testing |

| Certification | ISO 9001, ISO 14001, SGS | Basic | ISO/SGS |

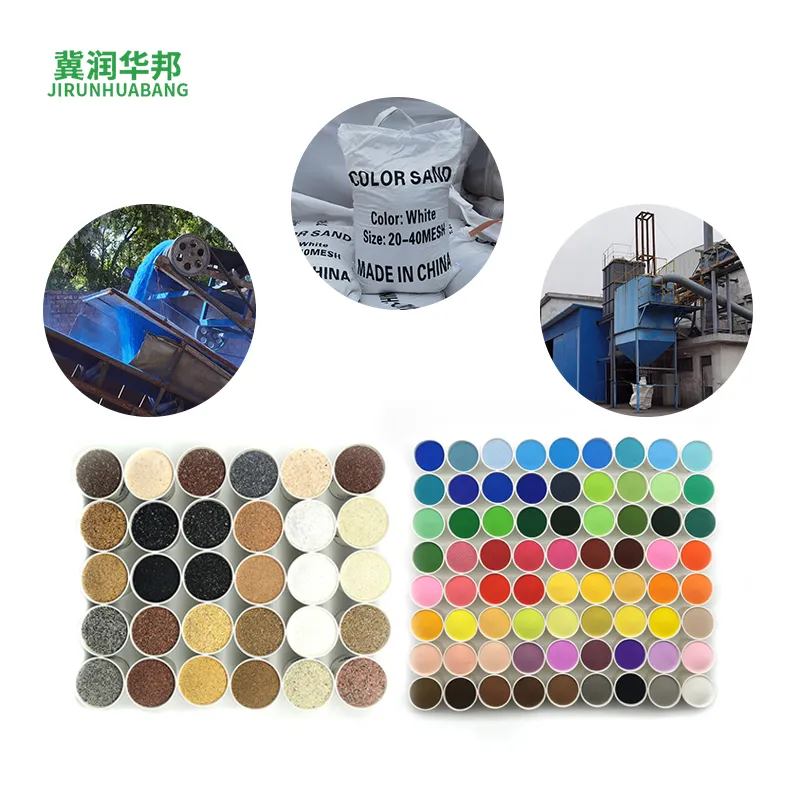

Raw Material Selection → Sand Grading & Purification → High-temperature Sintering [≥950°C, 2–4h] → Blending with Polymer Binders → CNC Fine Grinding & Homogenization → Quality Control (ISO/SGS) → Automated Packaging

• Material: 99.5% pure quartz & natural colored sand

• Process: Sintered at high temperatures for extreme density and color lock

• Machining: CNC grinding ensures <40 μm particle fineness

• Quality: Multi-stage ISO & SGS batch inspection—color, adhesion, VOC

- Natural Mineral Sand Base: Eco-derived, free from toxic additives, contributing to green-building credits (LEED/BREEAM).

- High-Temperature Sintering: Color pigments become microencapsulated within sand, providing fade-proof and chalk-resistant properties; resistance to acids, bases, saline environments, and UV.

- CNC Micro-Grinding: Ensures ultra-fine, even finish—scratch-resistant and pleasant to the touch.

- Low VOC, Odorless: Safe for hospital, school, food plant, and green residential applications; meets EU and US emission standards.

- Easy Customization: 35+ color palette; can match 200+ Pantone/architect designs.

- Longevity: Up to 20 years of color brilliance and zero surface degradation under ISO/ASTM cyclical climate simulation tests.

| Attribute | Runhuabang | Brand S* | Brand J* |

|---|---|---|---|

| Main Ingredient | Natural sintered color sand + acrylic polymers | Synthetic color chips, solvent | Synthetic sand, latex |

| Color Retention | >3,500h QUV®, retained | 2,400h, moderate fade | 2,100h, yellowing |

| VOC | <50g/L | 110g/L | 95g/L |

| Certifications | ISO 9001, 14001, SGS | ISO 9001 | ISO 9001 |

| Customization | Full, ~200 codes | Limited, ~40 codes | Limited |

| Service Life | 15–20 years | 8–10 years | 7 years |

| Heat Resistance | -25°C ~ 180°C | -10°C ~ 80°C | -5°C ~ 70°C |

Runhuabang empowers architects, engineers, and contractors with a broad color spectrum and tailor-made formulations. Customization services include texture, gloss level, and anti-slip or anti-biofilm properties, all validated under rigorous lab and field standards (ISO/ASTM).

- Petrochemical: Long-range corrosion protection for pipelines, tanks, and plant exteriors—maximized color stability in saline industrial zones.

- Metallurgy: Superior resistance to acid, alkali, and heat cycles—perfect for steel infrastructure and process plant interiors.

- Architecture: Cultured stone, luxury resorts, public buildings—genuine natural stone effects with Runhuabang Interior and exterior paint with natural color sand high temperature sintering color variety lasting beautiful.

- Waterworks/Public Works: UV-resilient and microbiologically inert for outdoor water features, swimming pools, and municipal pipelines.

- Healthcare: Odorless, ultra-clean finish for hospitals, clinics, and food prep zones (FDA/EU compliant).

The piping exteriors and walls of a large eco-industrial zone were coated with Runhuabang Interior and exterior paint with natural color sand high temperature sintering color variety lasting beautiful. After three years, independent SGS reports confirm 99.2% original color retention, with no blistering or corrosion events over two freeze-thaw winters (-22°C).

- Authoritative reference: Test data released in CoatingsWorld / SGS Lab 2023 (verified QUV/adhesion/lifetime tests).

- Daqing Petrochemical, China: “Surface is pristine after two harsh winters, no discoloration or peeling. Product fully met ISO 11507 endurance claims.”

- Wuhan Central Hospital: “VOCs tested at 43g/L, much lower than local requirement of 60g/L. Floor and wall finish is both durable and safe for surgery units.”

- Structural Engineering Solutions Ltd, EU: “We were impressed by the color matching service, stone-like textures, and fast-turnaround logistics (18 days from order to installation in Europe).”

- Standard Delivery: 10–15 days (Asia), 18–25 days (EU/NA, via sea or rail).

- Customization: Up to 1200kg/day (lab tested), full traceability on raw material and batches.

- Warranty: Minimum 8 years (interior) and 15 years (exterior), defect-free replacement or on-site technical support.

Free training, manual, and site guidance included. - Certifications: ISO 9001, ISO 14001, SGS, FDA (for healthcare use), GB/T applicable as per industry segment.

- Customer Service: 24/7 Email, live video support, bi-lingual site technicians.

Frequently Asked Questions (Technical/Professional Focus):

Explore more technical documentation and order samples ›

[1] Grand View Research. 2024. Global Decorative Coatings Market Size & Trends. Link.

[2] CoatingsWorld, 2023. SGS Report on Sintered Paint Durability. Link.

[3] ISO 11664, 11507, 1524, 12944 standards. International Organization for Standardization (ISO). Link.

[4] PaintSquare News (Industry Studies), 2023.