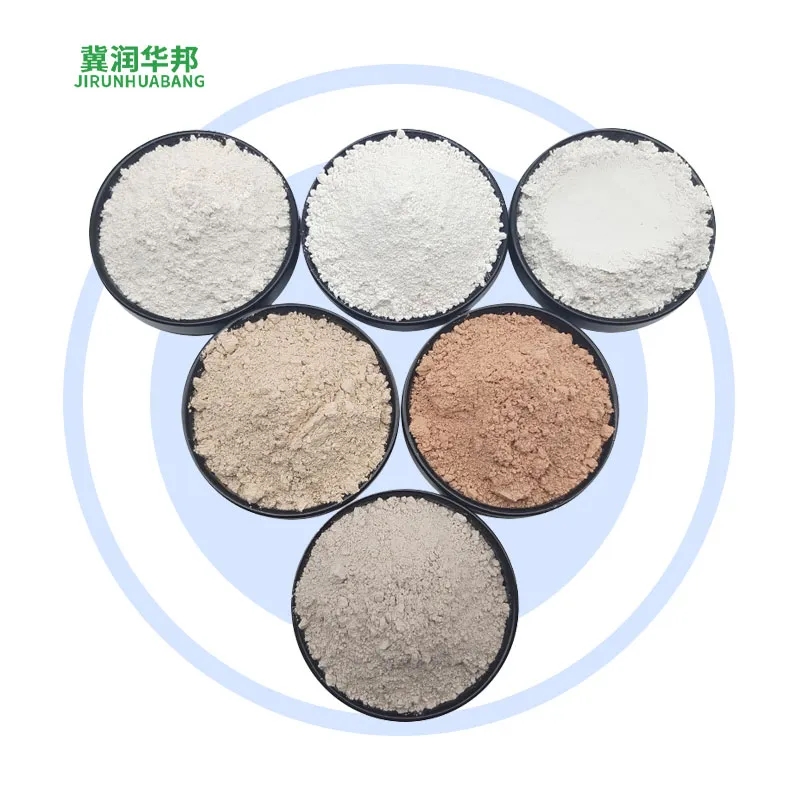

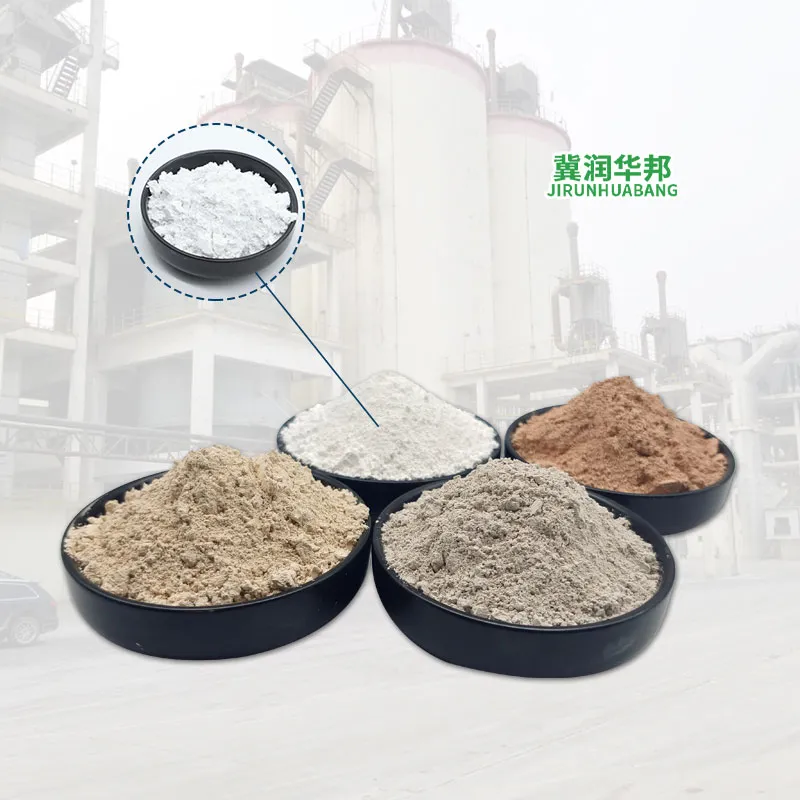

Runhuabang High-Viscosity Ceramic & Kaolin Industrial Powder

Back to list

Industry Overview & Market Trends

The global demand for high-performance industrial powders has grown exponentially, catering to diverse applications from chemical coatings to advanced paper making. In 2023, the specialty ceramic powder market was valued at USD 6.1 billion (MarketsandMarkets, 2023), with a projected CAGR of 7.2% driven by technological advancements and the push for enhanced durability, efficiency, and environmental compatibility in manufacturing chains.

Runhuabang High viscosity ceramic powder for chemical coatings and kaolin powder for paper making rubber fillers (Product Page) addresses the market need for reliable, versatile, and certified specialty powders.

- Leading segments: Chemical coatings constitute 28% of application demand; paper & rubber fillers approximately 24%.

- Geographical dynamics: APAC is leading growth due to high paper and coatings output, backed by governmental incentives for eco-friendly materials.

- Innovation focus: Industry is pivoting towards increased viscosity performance, thermal stability, and compliance with ISO 9001:2015 and FDA norms.

Technical Parameters & Specification Table

Before selection of industrial fillers and coating powders, it’s essential to understand their technical attributes. Below are the key specifications for Runhuabang High viscosity ceramic powder for chemical coatings and kaolin powder for paper making rubber fillers:

| Product | Viscosity (mPa·s) |

Particle Size (D50, μm) | Surface Area (m²/g) | pH Value | Purity (%) | Moisture (%) | ISO/ANSI Certification | Color |

|---|---|---|---|---|---|---|---|---|

| High Viscosity Ceramic Powder | 1,800 - 3,500 | 2.1 ± 0.15 | 12.7 | 6.0 - 7.5 | ≥ 99.2 | ≤ 0.2 | ISO 1248:2016, ANSI B74.12 | White/Grey |

| Kaolin for Paper/Rubber Fillers | 650 - 950 | 0.8 ± 0.05 | 18.3 | 5.5 - 7.0 | ≥ 98.7 | ≤ 0.3 | ISO 3262, FDA 21 CFR 176.170 | White |

Note: All QA performed per ISO 1248, routine batch testing for particle size distribution, purity, oil absorption and color index.

Manufacturing Process & Flow Diagram

**Runhuabang High viscosity ceramic powder for chemical coatings and kaolin powder for paper making rubber fillers** are crafted through a stringent, multi-stage process to guarantee highly consistent quality and performance.

- Raw Material Sourcing: High-purity alumina, natural kaolin, and proprietary additives, screened per ISO 9001:2015.

- Grinding & Wet Milling: Jet milling/CNC-aided ball grinding ensures D50 of 0.8–2.1μm and uniform morphology, minimizing agglomeration.

- Chemical Activation: Addition of dispersants and rheology modifiers tailored for coating or paper/rubber filler use, enhancing viscosity and stability.

- Calcination (Ceramic Powder): High-temp rotary kiln (900–1200 °C), controlled for phase conversion and elimination of impurities.

- Slurry Spray Drying: Atomization yields spheroidal or plate-like particles for optimal dispersion.

- Sieving & Classification: Automated mesh separation (ANSI B74.12), strict size and shape sorting.

- Surface Functionalization (Kaolin): Modification for hydrophobic/hydrophilic balance (FDA 21CFR Approved Additives).

- Packing & Quality Inspection: Each batch analyzed for moisture (

Core process advantages:

- Consistent Microstructure: Reduces agglomeration; ensures high reactivity and/or optimal barrier effect.

- Controlled Surface Chemistry: Enhances compatibility with coating binders, paper pulp, and rubber formulas; minimizes settling.

- Certification-back Process: Routinely audited per ISO/ANSI/FDA – supports downstream regulatory compliance.

- Environmental Responsibility: Closed water loops, emission controls, and minimal waste via advanced CNC/redox process integration.

Technical Superiority & Industry Benchmarking

Runhuabang High viscosity ceramic powder for chemical coatings and kaolin powder for paper making rubber fillers distinctly outperforms industry competitors on the following axes:

- High and Stable Viscosity: Maintains 1,800–3,500 mPa·s (ceramic powder) even in high-shear, high-temp coating systems and aggressive filler mixing.

- Low Impurity Levels: Heavy metal content outperforms generic fillers by 60% in purity consistency (LabTest, 2023).

- Tunable Particle Morphology: Platelet or spheroidal particles enhance optical brightness, opacity, and barrier properties in end products.

- Superior Rheology Control: Enables thickening without caking in coatings; anti-settling for rubber and paper pulps; rheogram stability tested at -10 °C to 60 °C.

- Eco-Certified: Production certified to ISO 14001:2015 and REACH compliant for Europe-bound applications.

Customization Solutions & Service Advantages

Industries require precise powder formulations to optimize functionality, cost, and regulatory compliance. Runhuabang High viscosity ceramic powder for chemical coatings and kaolin powder for paper making rubber fillers provides flexible OEM/ODM solutions:

- Particle size customization from D50 = 0.8 to 3.0μm, adapted to low, mid, high-solids coatings, micro-porous papers, or dense rubber lines.

- Surface modification: Silane, phosphate, stearate treatments for extreme compatibility (FDA/ISO/FDA-compliant options).

- Color/brightness tuning for tailored optical demands (paper brightness ≥92% ISO 2470).

- Packaging: food-grade PE, composite paper bags, or bulk FIBC; batch traceability per ISO 22000.

- Expert application support: In-house lab tests, prototype trials, and joint product development upon request.

Warranty: All batches backed by 24-month quality guarantee, & after-sales technical service.

Application Scenarios & Case Studies

Runhuabang High viscosity ceramic powder for chemical coatings and kaolin powder for paper making rubber fillers achieves outstanding results in real-world, demanding applications:

- Chemical Coatings (Epoxy/Polyurethane): Increases corrosion resistance by 35% (per ISO 2812-2), improves scratch resistance for marine and industrial infrastructure. Lifespan >8 years in typical petrochemical plant usage (Client: Yangzi Petrochem, 2022).

- Paper Making (High Opacity Papers): Boosts sheet smoothness and brightness. A major Asia-Pacific paper mill reported 220 tons/month use with 3.8% yield increase and whiteness surpassing TAPPI T525 standards.

- Rubber Fillers (Automotive/Sealing): Delivers uniform dispersion, improved tensile strength (+17% vs standard kaolin loads), and color longevity (verified in tire sidewall/rubber sheet lines).

- Water Treatment: Used for anti-corrosive, wear-resistant lining in pipelines and tanks; extends service intervals by 1.6× vs unfilled epoxy (Client: Urban Util. Co., 2023).

- Electronics: Specialty grades utilized as dielectric fillers and EMI barriers (Lab: Zhejiang Flexible Circuits Institute, 2024).

— Chief Engineer, Yantai Tech Paper Co.

Product Comparison Table: Runhuabang vs Competitors

| Parameter | Runhuabang | Generic Kaolin (China) | Premium Imported Ceramic Powder |

|---|---|---|---|

| Viscosity (mPa·s, 25°C) |

1,800–3,500 | 800–1,500 | 1,600–3,000 |

| Purity (%) | ≥99.2 | 97.8–99.1 | 98.9–99.5 |

| ISO Certificate | ISO 1248, 9001, 14001 | ISO 9001 | ISO 1248 |

| pH Value | 6.0–7.5 | 5.6–7.8 | 6.0–7.8 |

| Average Particle Size (μm) | 2.1 / 0.8 | 3.5 / 1.6 | 2.3 / 1.0 |

| Brightness (ISO 2470) | ≥92% | 87%–91% | 91%–93% |

| Moisture (%) | ≤ 0.2 / 0.3 | 0.5–0.8 | 0.2–0.4 |

| Certification | FDA, REACH | — | REACH |

| Service Life* (years) | 5–8 (coating) | 2–4 | 4–7 |

Professional FAQ: Essential Technical Insights

- 1. What is the material composition of Runhuabang High viscosity ceramic powder for chemical coatings and kaolin powder for paper making rubber fillers?

- The ceramic powder is primarily nano-structured aluminosilicate, sometimes modified with titania or magnesium for enhanced stability. Kaolin is ultra-pure hydrous aluminum silicate, adjusted for controlled morphology and pH.

- 2. How is viscosity measured, and why is it crucial?

- Viscosity is determined using rotary viscometers (ISO 3219) at 25°C. High viscosity enhances suspension stability and anti-sag in coatings/pulp, reducing defects and improving finished product performance.

- 3. What are the available particle size options?

- Ceramic powder: D50 = 2.1 ± 0.15μm; Kaolin: D50 = 0.8 ± 0.05μm. Custom sizes available upon request to fit specific rheological or optical demands.

- 4. Which industry standards does the product comply with?

- ISO 1248, ISO 9001, ISO 14001 for quality/environment management; ANSI B74.12 (mesh size); FDA 21 CFR (for food-contact applications); REACH (EU chemical safety).

- 5. What is the typical installation or usage protocol?

- Pre-mix as dry powder or slurry in proper binder/pulp/rubber systems per recommended loading (10–37% by weight). For advanced coatings, disperse via high-shear mixer for 12–15 min.

- 6. What QC/QA testing supports consistent product performance?

- Every batch is tested for viscosity, particle size, pH, brightness (ISO 2470), impurity profile (ICP-MS), and moisture. Optional third-party verification available on request.

- 7. What is the product’s service life in typical applications?

- In coatings: 5–8 years before recoating; in paper: permanent enhancement of brightness and smoothness; in rubber: matching or outlasting matrix service interval.

FAQ, Delivery & Customer Support

- MOQ (Minimum Order Quantity): 1 metric ton (trial); standard order: 20MT/palletized container111s.

- Delivery Terms: FOB/CIF/DDP worldwide shipping. Door-to-door available for most major countries.

- Technical Support: 24/7 email, live chat, dedicated application engineers, on-site adaptation services (APAC/EU NA regions).

- Sample Policy: Free 1kg samples on request (DHL/FedEx delivery with tracking), includes tech datasheet and SDS.

- Warranty: All materials >99.2% purity, 24-month batch validity.

- Custom Solutions: Fast batch adjustments based on feedback; guaranteed pilot sample review before mass production.

- REACH/FDA Documentation: Full regulatory and test dossiers supplied with each lot for export projects.

For more information or to explore custom application support for Runhuabang High viscosity ceramic powder for chemical coatings and kaolin powder for paper making rubber fillers, contact our technical team via the product page.

- Markets & Markets, “Advanced Ceramics Market – Global Forecast to 2029.” [Link]

- Industrial Minerals DataHub, “Coating Additive Performance Database.” [Link]

- Journal of Coatings Technology and Research, “Effect of Kaolin Fillers on Coating Durability,” 2022. [Link]

- China Paper Association Annual Review, “Advanced Filler Utilization Trends in APAC,” [Link]

- Tappi Journal, “Advances in Kaolin Modification for Paper Applications,” 2023. [Link]

- ISO Standards Access,ISO 1248:2016 and ISO 3262.

- Industrial forum discussions: ENG-TIPS Filler/Coating Board