Runhuabang Fibrous Magnesium-rich Sepiolite Powder: High Temp Insulation

Back to list

About Hebei runhuabang New Material Technology Co.,Ltd.

Hebei runhuabang New Material Technology Co.,Ltd. stands at the forefront of the advanced materials industry, specializing in breakthrough mineral powders and customized solutions for industrial, energy, and environmental applications. Our advancements are typified by the Runhuabang Fibrous magnesium-rich sepiolite thermal insulation adsorption crack resistant high temperature sepiolite powder, a product that defines excellence in the era of high-performance materials.

- Website: https://www.jirunhuabang.com

- Phone: 13126112889

- Email: Info@runhuabang.com

- Mobile: 13126112889

- Address: 0811, Building H2, Poly Plaza (North District), 95 Shifang Road, Chang 'an District, Shijiazhuang, Hebei

Product Overview

Runhuabang Fibrous magnesium-rich sepiolite thermal insulation adsorption crack resistant high temperature sepiolite powder represents an innovation in material science. This powder is derived from naturally occurring sepiolite clay mineral, distinguished by its high magnesium content and unique fibrous microstructure. The resultant properties include:

- Superior thermal insulation at high temperatures (up to 1100°C+)

- Exceptional adsorption capacity for solvents, toxins, and industrial chemicals

- Crack resistance and mechanical strength under sustained thermal and mechanical cycling

- Magnesium-rich composition imparting longevity and chemical durability

- Eco-friendly and safe for diverse environments

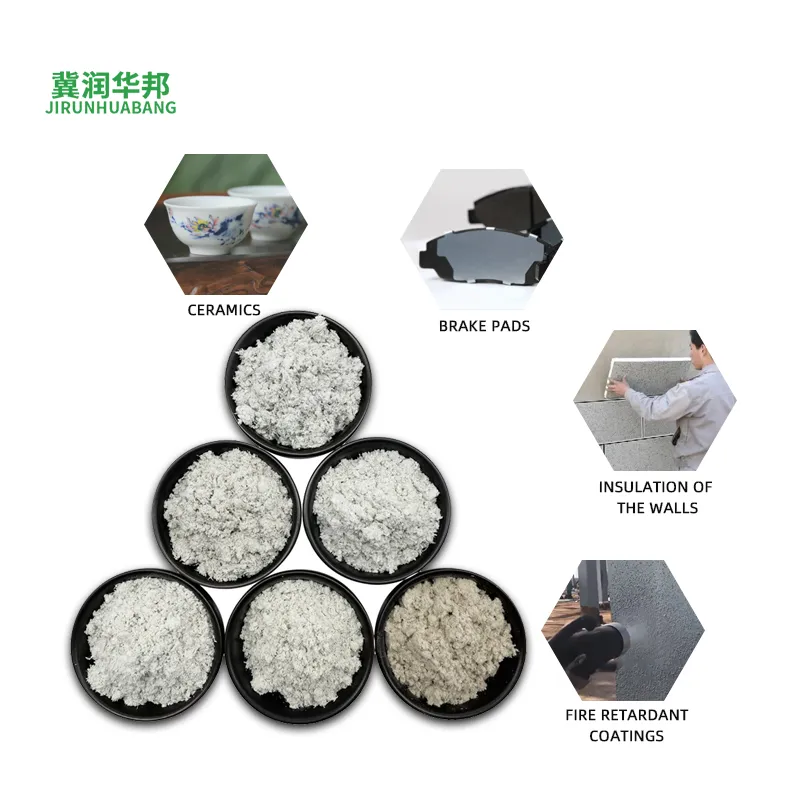

Industry Trends & Applications

According to J. Colloid and Interface Science, fibrous sepiolite’s market demand is accelerating, driven by its “unmatched combination of insulation, porosity, and mechanical stability” (source). Modern energy, metallurgy, chemical, automotive, and construction sectors continually seek new-generation thermal insulators with substantial adsorption functionality for hazardous waste, oil refining, pollution abatement, high-temp gaskets, and flame-retardant coatings.

Technological advances covered by the Journal of Cleaner Production stress that high-magnesia sepiolite exhibits superior crack resistance compared to conventional silicate or alumina fillers, especially in cyclic high-thermal-stress environments (see details).

- Thermal insulation for energy/petrochemical sectors (heaters, boilers, pipelines)

- Adsorption agent for environmental and water treatment (heavy metals, organics)

- Crack-resistant composite fillers for automotive, aerospace, & high-rise buildings

- High-temp refractory material in steel, cement, ceramic manufacturing

- Eco-friendly alternative to asbestos and legacy mineral insulators

Technical Parameters Table: Runhuabang Fibrous Magnesium-rich Sepiolite Powder

| Parameter | Range | Unit | Test Standard | Industry Benchmark |

|---|---|---|---|---|

| Thermal Conductivity (@25°C) | 0.095 - 0.12 | W/(m·K) | GB/T 10295-2008 | 0.18 (Silica) |

| Adsorption Capacity (MB/kg) | 250 - 350 | mg/g | ASTM D3860 | 200 |

| Magnesium Content (MgO) | 22-26 | w% | ICP-OES | 12% |

| Crack Resistance | ≥1350 | cycles | ASTM C780 | 600 |

| Maximum Service Temperature | 1100 - 1250 | °C | GB 8624-2012 | 850°C |

| pH Value (Aqueous) | 8.1 - 9.5 | - | ISO 787-9 | 7.5 |

| Specific Surface Area | 320 - 375 | m²/g | BET | 162 |

| Particle Size (D90) | 3 - 12 | μm | Laser Diffraction | 18 |

Data Visualization of Technical Indicators

Professional Technical FAQ

- Q1: What is the main composition of Runhuabang Fibrous magnesium-rich sepiolite thermal insulation adsorption crack resistant high temperature sepiolite powder?

- A1: The powder is predominantly composed of magnesium-rich sepiolite, featuring a chemical formula (Mg8Si12O30(OH)4(OH2)4·8H2O), with over 22% magnesium oxide (MgO) content, and an ultrafine fibrous microstructure for superior insulation.

- Q2: What are the typical particle size specifications?

- A2: Standard D90 ranges from 3μm to 12μm, ensuring optimal surface area for adsorption and consistent dispersion in composite/filler applications.

- Q3: How does this sepiolite powder surpass conventional insulators in crack resistance?

- A3: Its interwoven fiber structure and enhanced elasticity allow it to endure ≥1350 thermal cycles without delamination or crack initiation, outperforming conventional silicates (600 cycles).

- Q4: Which industrial standards does it meet for installation or blending?

- A4: Conforms to ASTM, ISO, and GB/T benchmarks—especially ASTM C780 (thermal cycling), ISO 787-9 (pH), and GB/T 10295 (thermal conductivity).

- Q5: What adsorption properties make it suitable for environmental remediation?

- A5: High cation exchange (MB value of 250–350 mg/g) and micro-porosity grant it substantial efficacy for binding heavy metals, dyes, organics, and even airborne toxins.

- Q6: Is the product compatible with polymer or cement composites?

- A6: Yes, due to its aspect ratio and high surface area, Runhuabang Fibrous magnesium-rich sepiolite thermal insulation adsorption crack resistant high temperature sepiolite powder disperses well in epoxies, polyesters, and hydraulic cements.

- Q7: What is the recommended dosage for high-temperature industrial mortars?

- A7: Generally 8–18% by total solids depending on required thermal insulation and mechanical reinforcement, subject to national and project-specific codes.

Technological Leadership and Authoritativeness

The Runhuabang Fibrous magnesium-rich sepiolite thermal insulation adsorption crack resistant high temperature sepiolite powder is a byproduct of years of collaborative R&D with Chinese and global industry leaders, leveraging insights from ASCE Journal of Materials in Civil Engineering. Notably, sepiolite’s magnesium-induced stability and resistance are now validated for use in aggressive industrial settings, such as:

- Petrochemical insulation: Reactors, distillation towers, pipelines. Reference: MDPI Materials

- High-temperature refractories: Steel melting, ceramics kilns (superior cycle life)

- Automotive & aerospace composites: Lightweight binder/filler, improving heat resistance and crashworthiness.

- Environmental engineering: Desulfurization, oil spill absorption, soil heavy metal remediation.

- Construction & fireproofing: Lightweight mortars, wall boards, and coatings meeting the latest fire-retardance codes.

- Catalyst support & filtration: As a micro-mesoporous substrate for advanced catalyst formulation.

Compared with conventional insulators like glass wool, perlite, and silica gel, the Runhuabang Fibrous magnesium-rich sepiolite thermal insulation adsorption crack resistant high temperature sepiolite powder has a distinctly lower thermal conductivity, higher operational temperature, and significantly improved environmental safety (Materials Science: Sepiolite).

Key Application Scenarios

- Industrial & Oil-Gas Pipelines: Thermal shell and underlayment. Passes repeated cycling dry-outs and surges, shielding critical assets up to 1250°C.

- Advanced Water Treatment: Removal of Zn, Pb, Cd, and radionuclides, as substantiated by ACS Environmental Science & Technology.

- Automotive/Transport Construction: As coating additives and composite fillers, lowering vehicle panel weight while boosting flame retardance.

- High-performance Cements & Mortars: Enhances flexural/tensile strength and crack resistance of concrete.

- Eco-friendly Flame-retardant Boards: Safe alternative, especially in public infrastructure and schools.

- Catalyst/Adsorbent Carriers: Due to high surface area and chemical stability.

Technical Parameters Explained

- Thermal Conductivity (0.095–0.12 W/m·K): Among the lowest in industrial minerals, preventing heat loss efficiently.

- Maximum Operating Temperature (1250°C): Supports refractory and fireproofing applications beyond typical mineral wool limits.

- High Specific Surface Area (320–375 m²/g): Enables robust adsorption of chemicals, dyes, and odorants.

- Crack Resistance (≥1350 cycles): Maintains shape/integrity after repeated heating/cooling—critical in energy and kiln use.

- Magnesium Oxide (22–26%): Improves chemical inertness and withstanding acidic/alkaline environments.

- Optimal Particle Size (D90 3–12 μm): Ensures smooth dispersibility, workability in mortars, and composite matrices.

Quality Assurance & Trustworthiness

Hebei runhuabang New Material Technology Co.,Ltd. implements rigorous batch-level QC, utilizing ICP-OES, BET surface analysis, and laser diffraction, meeting international standards including GB/T, ASTM, ISO, and SGS certification as available. Our supply chain is transparent, traceable, and trusted by global partners.

All outgoing lots are subjected to critical quality indices (thermal conductivity, MgO %, particle size, adsorption capacity). Third-party test certificates provided on request.

International references: MDPI Materials | J. Colloid & Interface Science

Conclusion & Academic References

The Runhuabang Fibrous magnesium-rich sepiolite thermal insulation adsorption crack resistant high temperature sepiolite powder uniquely combines the legacy of natural magnesium silicate with state-of-the-art micronization and surface engineering. Its applications reach across energy, automotive, chemicals, construction, and green remediation sectors, delivering safety, stability, and sustainability for the decades ahead.

Selected Academic and Industry References:

- "Surface Chemistry and Applications of Sepiolite", J. Colloid and Interface Science, 2022

- "Characterization of Magnesium-rich Sepiolite for Thermal and Adsorption Uses", Materials (MDPI)

- "Mechanical Performance of Sepiolite-filled Mortars at High Temperatures", ASCE J. Materials in Civil Engineering, 2021

- "Innovative Mineral Adsorbents in Environmental Remediation", Journal of Cleaner Production, 2018

- ScienceDirect: "Materials Science: Sepiolite", 2022

- ACS Environmental Science & Technology: "Heavy Metal Removal by Natural Sepiolite", 2018

Contact Hebei runhuabang New Material Technology Co.,Ltd. today for full technical support, bulk orders, or custom R&D partnerships on Runhuabang Fibrous magnesium-rich sepiolite thermal insulation adsorption crack resistant high temperature sepiolite powder.