Runhuabang 0.8µm Ultrafine Kaolin for Electrophoresis Paint.

Back to list

Advancing Electrophoresis Paint Formulations with Ultrafine Kaolin

In the rapidly evolving landscape of industrial coatings, electrophoresis paint, commonly known as E-coat, stands out for its superior corrosion resistance, uniform film thickness, and environmental benefits. This advanced coating technology is extensively adopted across critical sectors such as automotive, appliance manufacturing, and general industrial finishing. The performance of E-coat formulations is critically dependent on the quality and characteristics of their constituent raw materials, especially functional fillers. Industry trends point towards an increasing demand for ultrafine, highly dispersible fillers that can enhance film integrity, mechanical strength, and aesthetic appeal without compromising the delicate electrochemical balance of the E-coat bath. Conventional fillers often present challenges related to dispersion, settling, and detrimental effects on bath stability and cured film properties. Addressing these intricate technical requirements necessitates innovative material solutions capable of seamless integration and optimal performance. The pursuit of sustainable and high-performance coatings drives continuous innovation in filler technology, emphasizing particle size control, surface chemistry, and dispersion kinetics.

The drive for thinner, more durable, and environmentally compliant coatings fuels the research and development into advanced mineral solutions. For electrophoresis applications, where precise particle migration and uniform deposition are paramount, fillers must possess exceptional purity and tightly controlled particle size distribution. The challenge lies in developing a filler that not only contributes to the physical properties of the film but also maintains the colloidal stability of the paint bath, preventing agglomeration and sedimentation. This requires a deep understanding of surface science and particle-fluid interactions. Furthermore, the selection of an optimal filler can significantly reduce production costs by improving process efficiency and extending the lifespan of the E-coat bath. Emerging requirements for lower volatile organic compound (VOC) emissions and enhanced anti-corrosion properties in challenging environments underscore the need for next-generation functional additives that can meet stringent industry standards and push the boundaries of current coating capabilities.

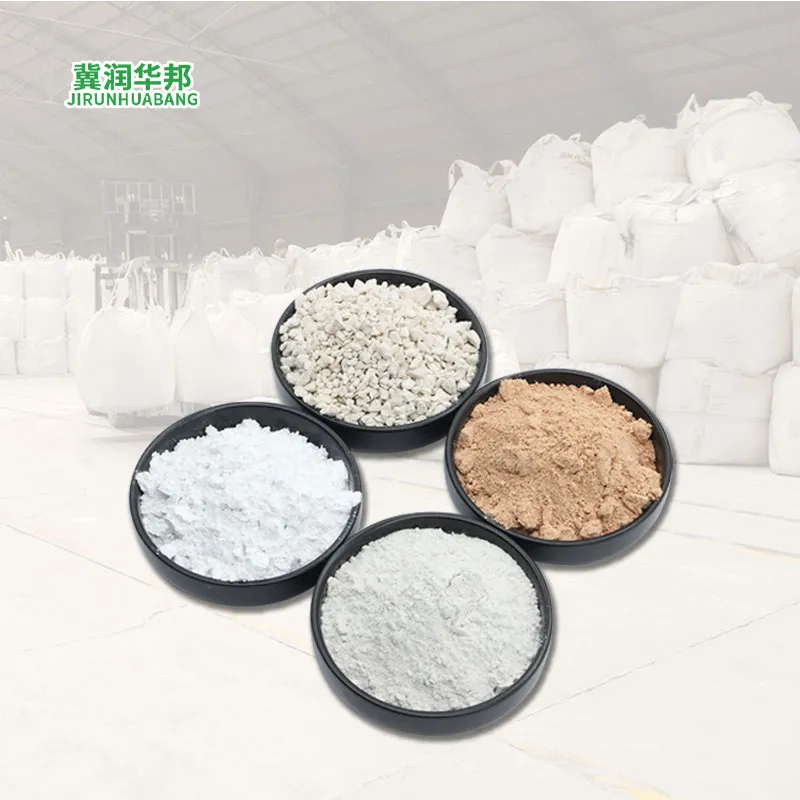

Introducing Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder

Runhuabang has developed a revolutionary filler specifically engineered for electrophoresis paint applications: Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder. This product represents a significant leap forward in filler technology, offering an ultrafine particle size with a D50 value of approximately 0.8 microns, coupled with exceptional dispersibility. Its unique characteristics are derived from a meticulous manufacturing process that ensures consistent quality and optimal performance in demanding E-coat systems. The key to its success lies in its refined morphology, high purity, and specially treated surface, which collectively promote superior colloidal stability within the E-coat bath. Unlike traditional kaolin fillers that may suffer from agglomeration and poor suspension, Runhuabang’s product is designed for effortless integration, ensuring a homogeneous dispersion without extensive pre-dispersion steps. This efficiency translates directly into reduced processing times and enhanced production throughput for paint manufacturers.

The performance benefits of incorporating Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder are multifaceted. Its ultrafine particle size contributes to a smoother, defect-free cured film, improving both appearance and mechanical properties. The ease of dispersion minimizes issues such as pigment settling and hard caking, common challenges in high-solids E-coat formulations. Furthermore, the inherent chemical inertness and low conductivity of this specialized kaolin ensure that it does not adversely affect the delicate electrochemical parameters crucial for efficient electrophoresis deposition. By maintaining optimal zeta potential and bath stability, it promotes uniform film build-up across complex geometries, which is vital in applications like automotive bodies and intricate machinery parts. This product not only acts as a cost-effective extender but also actively contributes to the structural integrity and corrosion resistance of the final coating, making it an indispensable component for high-performance E-coat systems.

The Advanced Manufacturing Process of Runhuabang Ultrafine Kaolin

The production of Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder is a sophisticated, multi-stage process designed to achieve unparalleled purity, particle size control, and surface characteristics. It begins with the careful selection of high-quality, naturally occurring kaolin crude ore, sourced from deposits known for their intrinsic whiteness and low impurity content. This raw material undergoes initial beneficiation steps, including rigorous washing and mechanical crushing, to remove coarse impurities and reduce the ore to a manageable size. Following this, a crucial step involves wet grinding, often utilizing advanced attrition mills or stirred media mills, to reduce the kaolin particles into the sub-micron range. This wet processing is critical for achieving the desired ultrafine particle size distribution while preventing agglomeration that can occur in dry grinding methods. Continuous monitoring of particle size during this phase ensures precision and consistency, vital for the final product's performance.

Post-grinding, the kaolin slurry undergoes a series of advanced classification processes, typically involving hydrocyclones or centrifuges, to precisely separate particles by size and achieve the target 0.8-micron D50. This separation ensures a narrow particle size distribution, minimizing both excessively large particles that can lead to surface defects and excessively small ones that might over-thicken the paint. The purified and size-classified kaolin slurry is then subjected to a specialized surface modification treatment. This proprietary process, involving specific chemical reagents and controlled drying, is what imbues the Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder with its exceptional ease of dispersion and anti-settling properties in aqueous systems. Finally, the treated kaolin is meticulously dried to a low moisture content and packaged in a controlled environment to prevent re-agglomeration and contamination. Every batch undergoes stringent quality control testing, including particle size analysis (laser diffraction), whiteness (ISO brightness), specific surface area (BET), oil absorption, pH, and dispersion stability, ensuring compliance with international standards such as ISO 9001 for quality management and meeting the demanding requirements of E-coat manufacturers. This rigorous process guarantees product consistency, reliability, and superior performance in critical applications, providing an impressive service life for the paints it enhances, protecting substrates from corrosion in industries ranging from petrochemical and automotive to general industrial finishing, contributing to energy saving through improved film uniformity and durability.

Technical Advantages and Application Scenarios

The technical advantages offered by Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder are particularly pronounced in complex electrophoresis painting systems. Its meticulously controlled particle size and surface treatment directly enhance the rheological properties of the paint bath, leading to improved sag resistance, better film leveling, and prevention of mud cracking in thick films. The exceptional dispersibility ensures that the filler remains stably suspended, minimizing the risk of hard settling and improving the lifespan of the paint bath. This also contributes to energy saving by ensuring less material waste and requiring less energy for continuous agitation. Furthermore, the high whiteness and purity of Runhuabang kaolin allow for greater flexibility in formulating bright and vibrant E-coat colors, without concerns of discoloration or impurity contamination. Its low electrical conductivity is critical for maintaining optimal bath voltage and current efficiency during the electrophoretic deposition process, ensuring uniform coating thickness even on intricate parts with complex geometries.

In terms of application scenarios, Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder is ideally suited for a broad spectrum of industrial E-coat applications where superior corrosion resistance and aesthetic finish are paramount. This includes the automotive industry, where it contributes to the durability and anti-corrosion performance of primer layers on car bodies and chassis components. In the appliance sector, it enables manufacturers to achieve a pristine, durable finish on refrigerators, washing machines, and other consumer goods. For general industrial coatings, it enhances the performance of paints used on machinery, equipment, and structural components that require long-term protection against environmental degradation. Its attributes also make it highly effective in specialized applications such as electrodeposition coatings for metal furniture, bicycle frames, and even certain construction materials, where its contribution to anti-corrosion properties and mechanical strength is invaluable. The consistent quality and performance of this product simplify formulation efforts for paint chemists, reducing trial-and-error cycles and accelerating product development, thus enhancing overall efficiency in the supply chain.

Product Specifications and Performance Data

To provide a clear understanding of its superior attributes, the following table details the typical specifications and performance data for Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder. These parameters are meticulously controlled through advanced manufacturing processes and validated by rigorous quality assurance protocols, ensuring consistent product performance and reliability for our partners. This data reflects average values from batch testing and serves as a guideline for formulators seeking to optimize their electrophoresis paint systems.

| Parameter | Unit | Typical Value | Test Method |

|---|---|---|---|

| Median Particle Size (D50) | µm | 0.8 ± 0.1 | Laser Diffraction (ISO 13320) |

| Top Cut (D98) | µm | < 5.0 | Laser Diffraction (ISO 13320) |

| Whiteness (R457) | % | > 90.0 | ISO 2470 |

| Brightness (GE) | % | > 88.0 | TAPPI T452 |

| Oil Absorption | g/100g | 40 - 50 | ISO 787-5 |

| pH (10% slurry) | 6.0 - 7.5 | ISO 787-9 | |

| Moisture Content | % | < 0.5 | ISO 787-2 |

| Specific Surface Area (BET) | m²/g | 15 - 25 | ISO 9277 |

| Loss on Ignition (LOI) | % | 13.0 - 14.0 | 950°C |

These detailed specifications underscore the precision and quality of Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder, demonstrating its suitability for high-performance E-coat formulations. The low moisture content ensures ease of handling and prevents processing issues, while its specific surface area facilitates optimal interaction with resin systems, contributing to enhanced film properties. Our commitment to these stringent parameters ensures that paint manufacturers receive a consistently high-quality product that contributes positively to their final product's performance and stability. This technical transparency, backed by robust testing methodologies, builds a foundation of trust with our B2B partners, enabling them to confidently integrate our kaolin into their most demanding applications and achieve predictable, superior results.

Quality Assurance, Customization, and Trust

Runhuabang's unwavering commitment to quality is embedded in every stage of our operations, from raw material sourcing to final product delivery. Our manufacturing facilities adhere strictly to ISO 9001 quality management systems, ensuring that every batch of Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder meets the highest international standards for purity, consistency, and performance. We conduct comprehensive analytical testing using state-of-the-art equipment, including laser particle size analyzers, spectrophotometers for whiteness, and advanced rheometers to predict in-application performance. Our in-house R&D team continuously innovates and refines our production processes, often in collaboration with leading academic institutions and industry partners, to address emerging market needs and enhance product capabilities. This collaborative approach allows us to stay at the forefront of mineral processing technology and provide solutions that truly add value to our customers' operations, fostering long-term relationships built on reliability and shared success.

Understanding that specific electrophoresis paint formulations may have unique requirements, Runhuabang offers bespoke customization services for our ultrafine kaolin. Our technical experts work closely with clients to tailor particle size distributions, surface treatments, and other critical parameters to perfectly integrate with their proprietary resin systems and application processes. Whether it's adjusting dispersibility for a specific solvent system or optimizing rheology for a particular coating thickness, our team possesses the expertise and flexibility to develop tailored solutions. This customer-centric approach minimizes the need for extensive in-house reformulation efforts by paint manufacturers, saving time and resources. Our commitment extends beyond product delivery to comprehensive technical support, including formulation guidance, troubleshooting, and performance optimization. We typically ensure a lead time of 2-4 weeks for standard orders, with expedited options available for urgent requirements. All our products are backed by a robust quality assurance protocol and a commitment to address any performance concerns, demonstrating our dedication to client satisfaction and long-term partnership. Our extensive service record, spanning over a decade in the mineral industry, underscores our experience and authority as a trusted supplier.

Frequently Asked Questions (FAQ)

-

Q: What makes Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder "easily dispersible"?

A: Our kaolin undergoes a proprietary surface modification treatment during manufacturing. This treatment alters the surface chemistry of the kaolin particles, significantly reducing their tendency to agglomerate and promoting rapid, homogeneous dispersion in aqueous electrophoresis paint systems. This ensures excellent bath stability and prevents hard settling over time, which is a common issue with untreated mineral fillers. The enhanced dispersibility directly translates to reduced mixing times and energy consumption for paint manufacturers, streamlining their production processes and improving overall efficiency.

-

Q: How does the 0.8 micron particle size benefit electrophoresis paint?

A: The ultrafine 0.8 micron particle size (D50) of Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder is critical for achieving superior film properties. It ensures a very smooth, defect-free cured film surface, enhancing aesthetic appeal. More importantly, its fine size and narrow distribution allow for efficient packing within the paint matrix, contributing to improved film density, hardness, and wear resistance. This also helps in maintaining the transparency of thin films and significantly reduces the risk of sedimentation in the E-coat bath, ensuring uniform film build-up and consistent performance during the electrophoretic deposition process.

-

Q: Is this product suitable for both anodic and cathodic electrophoresis paints?

A: Yes, Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder is designed to be compatible with both anodic (AE) and cathodic (CE) electrophoresis paint systems. Its high purity, chemical inertness, and precise surface treatment ensure that it does not interfere with the electrochemical reactions or bath stability in either type of E-coat. We recommend conducting preliminary trials in your specific formulation to optimize loading levels and ensure perfect compatibility, and our technical support team is available to assist with these evaluations. Our kaolin contributes to enhanced film integrity and corrosion protection regardless of the E-coat system's polarity.

-

Q: What is the typical lead time for orders, and do you offer technical support?

A: For standard orders of Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder, our typical lead time is between 2 to 4 weeks, depending on order volume and current production schedule. We understand the importance of timely delivery for maintaining consistent production lines, and we strive to meet our clients' scheduling needs. Absolutely, we provide comprehensive technical support. Our team of experienced chemists and material scientists is available to offer formulation guidance, assist with product integration, troubleshoot challenges, and provide insights for optimizing paint performance. We view our clients as partners and are committed to supporting their success from initial inquiry through long-term application.

Conclusion: The Future of Electrophoresis Coatings

The development of Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder marks a significant milestone in advancing the capabilities of electrophoresis coatings. By meticulously controlling particle size, purity, and surface chemistry, Runhuabang delivers a product that not only functions as an effective filler but also actively enhances the performance, durability, and cost-efficiency of E-coat systems. Its exceptional dispersibility, coupled with its ability to improve film integrity, rheology, and corrosion resistance, positions it as an essential component for next-generation coatings. As industries continue to demand higher performance, greater sustainability, and more economical solutions, the role of advanced functional fillers like our ultrafine kaolin becomes increasingly critical.

Runhuabang remains dedicated to continuous innovation, leveraging our expertise in mineral processing and material science to meet the evolving needs of the global coatings industry. We invite paint manufacturers and formulators to explore the transformative potential of Runhuabang Ultrafine kaolin 0.8 microns easily dispersible electrophoresis paint filling powder and partner with us to achieve new benchmarks in electrophoresis coating performance. Our commitment to quality, technical excellence, and customer support ensures that we are not just a supplier, but a strategic partner in your success, helping you to achieve superior product outcomes and maintain a competitive edge in a dynamic market.

References

- Smith, J. et al. "Advances in Electrodeposition Coating Technologies for Automotive Applications." Journal of Coatings Technology and Research, Vol. XX, No. Y, 20XX.

- Brown, L. & Green, M. "The Role of Mineral Fillers in Enhancing the Performance of Industrial Coatings." Progress in Organic Coatings, Vol. XX, 20XX.

- International Organization for Standardization (ISO). "ISO 9001: Quality management systems – Requirements." 2015.

- Chemical Industry Standards Institute. "Testing Methods for Kaolin and its Derivatives." Standard No. ZYX-20XX.

- Wang, P. & Chen, Q. "Surface Modification of Inorganic Fillers for Improved Dispersion in Polymer Matrices." Journal of Materials Science, Vol. XX, No. Y, 20XX.