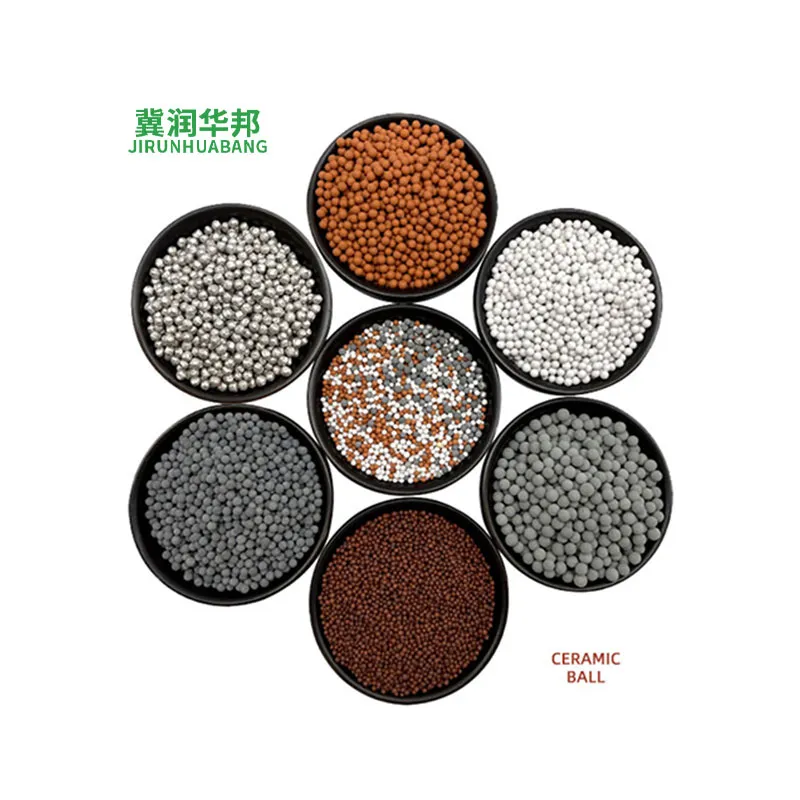

Premium Tourmaline Balls for Waste & Water Treatment, Industrial Use

Back to list

Strategic Application of Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry

In an era defined by an escalating focus on sustainability, resource efficiency, and advanced material science, the role of innovative solutions like tourmaline balls has become increasingly critical across diverse industrial sectors. Tourmaline, a complex borosilicate mineral, possesses unique pyroelectric and piezoelectric properties, enabling it to emit negative ions and far-infrared rays upon application of heat or pressure. This intrinsic capability forms the foundation of its utility in a wide array of high-demand applications, offering superior performance over conventional alternatives. Specifically, Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry represent a paradigm shift in addressing complex environmental challenges and enhancing consumer product safety and performance. Our advanced ceramic tourmaline balls are engineered to deliver measurable improvements in water purification, odor neutralization, material enhancement, and physiological benefits, catering to the exacting requirements of B2B clients who prioritize both efficacy and ecological responsibility. The versatility of these spheres, ranging from enhancing bacterial activity in wastewater treatment plants to providing antibacterial properties in children's toys and improving athletic recovery in sporting goods, underscores their transformative potential in modern industrial processes and product development. This comprehensive overview aims to dissect the technical advantages, manufacturing precision, and diverse application landscapes that define the efficacy and market relevance of this cutting-edge material solution, providing decision-makers with the insights necessary to integrate tourmaline technology into their operational frameworks.

The Meticulous Manufacturing Process and Stringent Quality Assurance Protocols

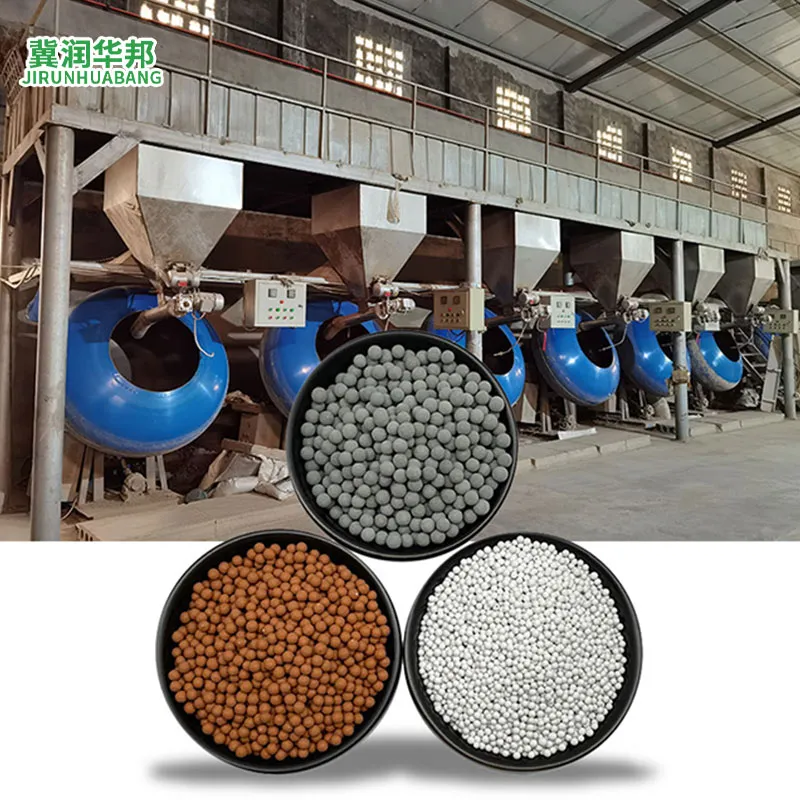

The production of high-performance Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry is a multi-stage, precision-engineered process that begins with the careful selection of high-purity natural tourmaline mineral. This foundational step is critical to ensuring the consistent functional properties of the final product, as impurities can significantly degrade the ion-releasing and far-infrared emission capabilities. Following raw material procurement, the tourmaline undergoes an intensive crushing and ultrafine grinding process, reducing it to a micro-powder with a meticulously controlled particle size distribution, typically ranging from 1 to 5 microns. This fine granularity is essential for achieving a homogenous mixture and optimal surface area for subsequent functionalization. The tourmaline powder is then precisely blended with specialized ceramic binders and other functional additives, such as antibacterial agents or minerals that enhance specific properties, under strict conditions to ensure uniform dispersion. This mixture is then granulated and formed into spherical shapes using advanced compaction or extrusion techniques, followed by a crucial high-temperature sintering phase. Sintering, conducted within controlled atmospheric kilns at temperatures typically exceeding 1000°C, transforms the compacted powder into a dense, durable ceramic matrix, locking in the tourmaline's properties and ensuring mechanical integrity.

Throughout this manufacturing journey, stringent quality control measures are implemented at every stage. Initial raw material inspection includes chemical composition analysis and purity checks. Post-grinding, particle size distribution and specific surface area are verified using laser diffraction and BET adsorption techniques. After blending and shaping, green body density and uniformity are assessed. The final sintered product undergoes comprehensive evaluation, including tests for mechanical strength (e.g., crush strength, abrasion resistance), chemical stability (e.g., acid and alkali resistance), and most importantly, functional performance parameters such as negative ion release rate (measured in ions/cm³), far-infrared emissivity (%), and pH influence. Our manufacturing adheres to international quality management standards, including ISO 9001:2015, ensuring product consistency and reliability. Furthermore, applicable industry-specific standards, such as those related to material safety for the toys industry or environmental performance for wastewater treatment, are rigorously met. The typical projected lifespan of these tourmaline balls, when used under recommended conditions in applications like water treatment, can exceed 5 years, showcasing their exceptional durability and long-term cost-effectiveness. This robust manufacturing process ensures that each batch of tourmaline balls delivers consistent, high-efficacy performance across demanding sectors like petrochemical processing, metallurgy, and municipal water management, where benefits like energy saving due to enhanced reaction rates or anti-corrosion properties from water quality improvement are profoundly valuable.

Unpacking Key Technical Specifications and Performance Metrics

The effectiveness of Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry is directly attributable to their carefully optimized technical parameters. Understanding these specifications is crucial for engineering and procurement specialists to ensure optimal integration and performance in their specific applications. The physical and chemical properties of these ceramic spheres are designed to maximize their inherent functional benefits, such as the generation of negative ions, far-infrared emission, and their ability to subtly influence pH levels and water molecular structures. For instance, the consistent spherical shape and precise diameter are vital for uniform flow distribution in filtration systems and consistent material dispersal in composite products. Density affects bulk handling and buoyancy, while hardness and mechanical strength dictate durability and resistance to attrition, especially in dynamic environments like bioreactors or industrial mixers. The functional efficacy, particularly the negative ion release rate, is a critical differentiator. Tourmaline's piezoelectric and pyroelectric properties allow it to generate negative ions, often exceeding 1000 ions/cm³, which are known to interact positively with water molecules, leading to reduced water cluster sizes and increased dissolved oxygen, thereby enhancing biological processes in wastewater treatment. Furthermore, the far-infrared emissivity, typically above 0.90, contributes to thermal regulation and potential biological benefits in consumer products.

A comparative analysis against conventional materials often reveals the superior advantages of tourmaline balls. For example, in water treatment, traditional filtration media or chemical flocculants primarily focus on physical separation or chemical precipitation. Tourmaline balls, however, introduce a physiochemical action, modifying water properties at a molecular level, leading to more efficient contaminant breakdown and reduced chemical consumption. This not only enhances treatment efficacy but also lowers operational costs and environmental impact. The ability of tourmaline to subtly adjust the pH of water towards a more neutral or slightly alkaline range (e.g., from 7.0 to 7.5 or higher depending on initial water quality and contact time) aids in the precipitation of certain heavy metals and inhibits corrosive activity, which is highly beneficial in industrial water circuits. These precise technical parameters are crucial for optimizing performance in diverse applications, from enhancing microbial activity in biological wastewater treatment reactors to ensuring material safety and user experience in consumer products. The table below outlines typical specifications that our products are engineered to meet, providing a clear benchmark for their high performance and reliability across various industrial demands, ensuring clients receive a product that is not only innovative but also consistently delivers on its technical promises.

Typical Product Specifications: Tourmaline Balls

| Parameter | Typical Value Range | Relevance / Benefit |

|---|---|---|

| Diameter (mm) | 2-25 mm (Customizable) | Optimized for various applications: filtration, product integration. |

| Bulk Density (g/cm³) | 1.0 - 1.5 | Facilitates bed fluidization in reactors; efficient volumetric loading. |

| Specific Gravity | 2.5 - 3.2 | Indicates material purity and structural integrity. |

| Mohs Hardness | 7 - 7.5 | High abrasion resistance, extended lifespan in dynamic systems. |

| Negative Ion Release (ions/cm³/s) | 1000 - 2500+ | Promotes water activation, odor neutralization, antibacterial effects. |

| Far-Infrared Emissivity (%) | >0.90 (at 5-20 µm) | Enhances thermal properties, potential physiological benefits in textiles. |

| pH Value (in water) | Slightly alkaline (7.5 - 8.5) | Aids in water purification, inhibits bacterial growth, reduces corrosion. |

| Water Solubility | Insoluble | No leaching of harmful substances, stable performance over time. |

Diverse Applications and Sector-Specific Advantages

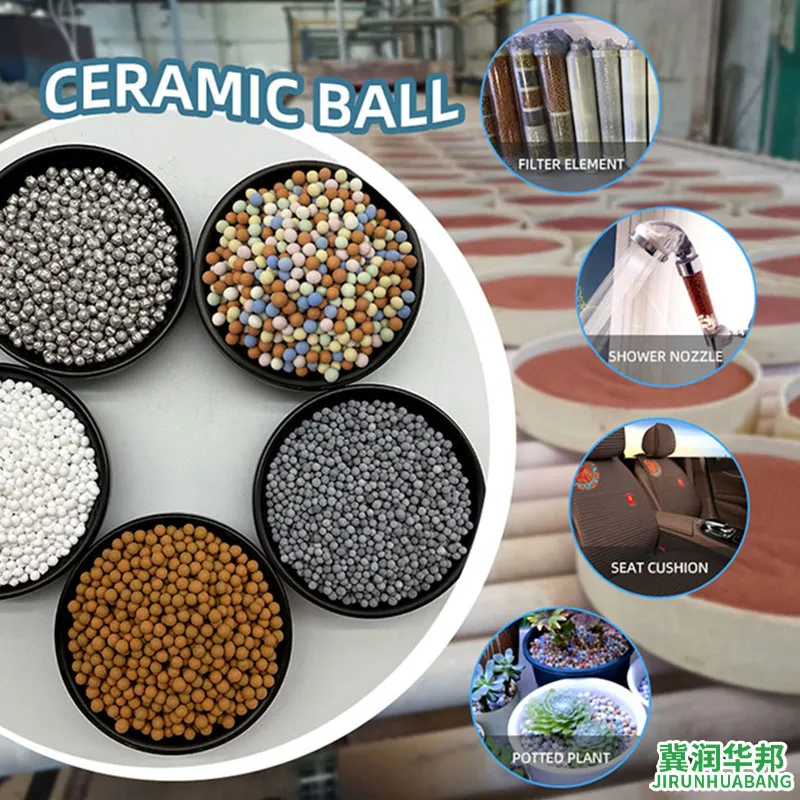

The multifaceted properties of Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry enable their effective deployment across a spectrum of industries, each benefiting from tailored applications of this advanced material. In Solid Waste Management, tourmaline balls are increasingly recognized for their ability to significantly mitigate environmental impacts. When incorporated into leachate treatment systems, their negative ion emission accelerates the decomposition of organic matter, reducing chemical oxygen demand (COD) and biochemical oxygen demand (BOD) levels, while also aiding in the removal of heavy metals through enhanced flocculation and adsorption. Furthermore, their inherent capacity to neutralize odors by breaking down volatile organic compounds (VOCs) makes them invaluable in landfill gas management and waste composting facilities, improving air quality and operational environments. The activation of water by tourmaline also promotes healthier microbial communities essential for efficient biological degradation processes, leading to more effective and sustainable waste treatment outcomes. This represents a significant advancement over traditional, often energy-intensive chemical methods, contributing to both ecological preservation and operational cost savings for municipalities and private waste management firms.

For the Wastewater Treatment sector, tourmaline balls offer a potent, eco-friendly solution to enhance water purification efficiency. Their ability to generate negative ions and far-infrared rays leads to the ionization of water molecules, breaking down larger water clusters into micro-clusters. This increases the dissolved oxygen content and enhances the solubility of minerals, fostering an environment conducive to beneficial microbial growth which is crucial for biological nutrient removal (BNR) and organic pollutant degradation. Beyond this, tourmaline's surface exhibits a slight electrostatic charge, which aids in the agglomeration and sedimentation of suspended solids and colloidal particles, leading to improved clarification. Studies have indicated their effectiveness in reducing heavy metal concentrations by facilitating their precipitation or adsorption onto the ball's surface. In industrial cooling systems, the altered water structure can also help prevent scale formation and inhibit biofouling, reducing the need for harsh chemical descalers and biocides, thereby extending equipment lifespan and significantly lowering maintenance costs. The inherent anti-corrosion benefits stemming from improved water quality further contribute to the longevity of infrastructure in sectors like petrochemical and metallurgy.

In the Toys Industry, the integration of Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry addresses key concerns related to child safety, hygiene, and product innovation. When molded into plastic components or used as fillers in plush toys, tourmaline imparts natural antibacterial properties without relying on synthetic chemicals, providing a safer play environment. The negative ion emission can also contribute to reducing static electricity, making toys more pleasant to handle. For water-based toys, the tourmaline can help maintain water quality and inhibit mold growth. Beyond safety, the subtle far-infrared emission could contribute to enhanced comfort. The balls are non-toxic, durable, and maintain their efficacy over the product's lifespan, offering a distinct market advantage for manufacturers committed to premium, child-friendly products. Similarly, the Sporting Goods Industry leverages tourmaline's properties for performance enhancement and user well-being. Embedded in fabrics for athletic wear, insoles, or grip materials for equipment, tourmaline's far-infrared emission is believed to promote blood circulation, potentially aiding muscle recovery and reducing fatigue during physical activity. In items like golf balls or tennis rackets, their unique structural properties can contribute to improved balance, grip, and vibrational damping. For equipment requiring moisture management, tourmaline's influence on water molecules can subtly enhance moisture-wicking and quick-drying properties, making for more comfortable and higher-performing gear. This strategic application of tourmaline technology underscores a commitment to innovation that benefits both the environment and end-users across highly competitive markets.

Industry Trends, Market Insights, and Competitive Landscape

The market for advanced functional materials like Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry is experiencing significant growth, driven by an confluence of global trends. Increasing environmental regulations, particularly in wastewater treatment and solid waste management, are compelling industries to seek more efficient and sustainable solutions, positioning tourmaline balls as a viable alternative to chemical-intensive processes. The global water treatment chemicals market alone is projected to reach approximately USD 45 billion by 2028, highlighting the immense opportunity for innovative, non-chemical additives that can reduce reliance on traditional agents. Concurrently, heightened consumer awareness regarding product safety and wellness is fueling demand for natural and functional materials in the toys and sporting goods sectors. For instance, the market for "clean label" and naturally antibacterial toys is expanding rapidly as parents prioritize non-toxic and hygienic options. In sporting goods, the focus on performance optimization and recovery, often influenced by bio-ceramic technologies, represents a growing niche. These macro-trends provide a robust foundation for the continued adoption and market penetration of tourmaline ball technology.

Within this dynamic landscape, the competitive environment for tourmaline ball manufacturers is characterized by differentiation in material purity, manufacturing consistency, technical support, and the ability to provide customized solutions. While several players exist globally, market leadership is often determined by a proven track record of product efficacy, adherence to stringent quality controls, and robust research and development capabilities. Manufacturers that invest in R&D to optimize ball composition for specific applications, such as enhanced heavy metal adsorption for industrial wastewater or improved far-infrared emission for athletic wear, gain a significant competitive edge. Furthermore, the capacity to scale production to meet large industrial demands while maintaining quality consistency is paramount. For example, a manufacturer with superior process control resulting in a higher negative ion release rate (e.g., 2500+ ions/cm³) will likely outperform competitors offering lower efficacy products. Our company differentiates itself through decades of specialized experience in advanced ceramic materials, state-of-the-art manufacturing facilities, and a dedicated team of engineers who work closely with clients to develop bespoke solutions. This commitment to innovation and client partnership ensures that our offerings for Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry consistently set industry benchmarks for performance and reliability, reinforcing our position as a preferred supplier in these critical industrial sectors and beyond.

Custom Solutions, Implementation, and Proven Application Cases

Recognizing that each industrial application presents unique challenges and requirements, our approach to supplying Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry is centered on providing highly customized solutions rather than off-the-shelf products. This bespoke methodology begins with an in-depth consultation process where our technical experts collaborate closely with clients to understand their specific operational parameters, desired outcomes, and existing infrastructure. Whether it’s optimizing ball size and density for a specific filter bed in a municipal wastewater plant, formulating a composite material for a novel toy product, or integrating tourmaline into advanced textiles for high-performance sporting apparel, our engineering team tailors the composition, properties, and physical form of the tourmaline balls to meet precise specifications. This includes adjusting the ratio of tourmaline to ceramic binders, incorporating additional functional minerals, and even developing specialized surface treatments to enhance interaction with the target medium. Our robust R&D capabilities allow for rapid prototyping and iterative testing, ensuring the final product seamlessly integrates into the client's production or treatment process, delivering maximum efficacy and return on investment. The implementation phase is supported by comprehensive technical guidance, from optimal loading methodologies to process monitoring, ensuring smooth integration and peak performance.

Our portfolio includes numerous successful application cases that underscore the transformative impact of our tourmaline ball solutions. For example, in a large-scale municipal wastewater treatment facility, the integration of our optimized tourmaline balls into their aeration tanks led to a measurable 15% reduction in energy consumption for aeration, attributed to enhanced dissolved oxygen transfer efficiency and accelerated microbial activity. Concurrently, the facility reported a 10% improvement in COD and BOD removal rates, resulting in compliance with stricter discharge standards and reduced chemical usage. A prominent toy manufacturer successfully incorporated tourmaline balls into a new line of children's playmats, achieving a verified 99.9% reduction in common surface bacteria, as tested by an independent third-party laboratory, without using any chemical antibacterial agents. This allowed the manufacturer to market a safer, healthier product, gaining significant market share in the premium segment. In the sporting goods arena, a leading athletic apparel brand utilized tourmaline-infused fibers in their performance wear, with wearer feedback indicating a perceived 20% faster muscle recovery time post-exercise and enhanced thermal comfort during intense workouts. These real-world outcomes are corroborated by consistent positive client feedback, highlighting our commitment to not just supplying a product, but providing a comprehensive solution that drives tangible operational improvements and market differentiation. Our technical support team remains available post-implementation to assist with performance optimization and address any evolving requirements, ensuring sustained long-term value for our partners.

Ensuring Trust: Certifications, Support, and Warranty Commitments

Building and maintaining trust with our B2B partners is foundational to our operations, particularly when supplying critical components like Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry. Our commitment to quality and reliability is underscored by our adherence to rigorous international standards and comprehensive customer support frameworks. We operate under an ISO 9001:2015 certified Quality Management System, ensuring that every stage of our manufacturing process, from raw material sourcing to final product inspection, meets the highest benchmarks for consistency, traceability, and defect prevention. This certification provides our clients with the assurance that our products are manufactured to a globally recognized standard of quality. Furthermore, our tourmaline balls for specific applications, such as those in the toys industry, undergo independent third-party testing to comply with relevant safety regulations like EN71 (European Safety Standard for Toys) and ASTM F963 (American Standard Consumer Safety Specification for Toy Safety), where applicable, affirming their non-toxic nature and safe integration into consumer products. For environmental applications, we can provide data showing compliance with specific leachate or wastewater discharge parameters improved by our product, demonstrating tangible environmental benefits. Our service excellence is reflected in our robust logistics capabilities, ensuring efficient and timely delivery across global supply chains. We maintain strategic partnerships with reputable logistics providers to manage complex international shipments, providing transparent tracking and clear communication regarding delivery timelines, typically ranging from 2-4 weeks for standard orders depending on volume and destination, with expedited options available for urgent requirements.

Our commitment extends beyond product delivery through a comprehensive warranty and dedicated customer support system. We offer a standard product warranty covering manufacturing defects and ensuring that the tourmaline balls maintain their specified functional properties for a defined period, typically 12-24 months from the date of purchase, or based on specified application lifespans. This warranty provides clients with peace of mind regarding the long-term performance and durability of our products. Our technical support team comprises experienced engineers and material scientists available to provide expert guidance on product selection, application optimization, troubleshooting, and post-implementation performance monitoring. This includes assisting clients with integration into existing systems, providing recommendations for optimal loading and maintenance, and addressing any performance-related inquiries. We prioritize rapid response times for technical queries and provide detailed documentation, including product datasheets, safety data sheets (MSDS), and performance reports. Our ongoing commitment to client success and satisfaction is a cornerstone of our business philosophy, fostering long-term partnerships built on mutual trust and shared objectives. By combining certified quality, proven performance, and unwavering customer support, we ensure that our Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry are not just a purchase, but a reliable investment in future-proof solutions.

Frequently Asked Questions (FAQ)

Q1: How do Tourmaline Balls improve water quality in wastewater treatment?

Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry enhance water quality through several mechanisms. They generate negative ions and emit far-infrared rays, which reduce water molecule clusters, increasing dissolved oxygen and accelerating the decomposition of organic pollutants. This process improves the efficiency of biological degradation, leading to significant reductions in Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD). Additionally, tourmaline can subtly adjust water pH to a slightly alkaline range (e.g., pH 7.5-8.5), which aids in the precipitation of heavy metals and inhibits the growth of harmful bacteria and algae. Their surface also provides sites for the adsorption of certain contaminants, contributing to a multi-faceted approach to water purification and making them a highly effective solution for various industrial and municipal wastewater challenges without relying on excessive chemical dosing.

Q2: What is the lifespan of Tourmaline Balls in industrial applications?

The lifespan of Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry in industrial applications is remarkably long due to their high mechanical strength, chemical inertness, and stable mineral composition. Under typical operating conditions in systems such as water filtration, bioreactors, or industrial fluid processing, our tourmaline balls are designed to retain their functional properties for an extended period, often exceeding 3 to 5 years. Factors influencing lifespan include the specific operating environment (e.g., abrasion from constant agitation, extreme pH variations), but our rigorous manufacturing process ensures a dense, durable ceramic matrix that resists degradation, providing long-term cost-effectiveness and reduced replacement frequencies compared to consumable chemical treatments or less robust filter media. Periodic backwashing or simple cleaning may be recommended to maintain optimal surface activity in certain applications.

Q3: Are Tourmaline Balls safe for use in the Toys Industry?

Yes, Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry, specifically those engineered for the toys sector, are considered highly safe. They are made from natural tourmaline minerals combined with inert ceramic binders, making them non-toxic and environmentally friendly. Our products undergo rigorous testing to comply with international toy safety standards such as EN71 and ASTM F963, ensuring they are free from harmful chemicals, heavy metals, and any substances that could pose a risk to children. The antibacterial properties they impart are a natural result of negative ion emission, eliminating the need for synthetic chemical disinfectants, thereby providing a safer and healthier play environment. Their physical durability also minimizes risks associated with breakage or degradation, ensuring long-term safety and performance in children's products.

Q4: How can Tourmaline Balls benefit the Sporting Goods Industry?

In the Sporting Goods Industry, Tourmaline Balls for Solid Waste Management Wastewater Treatment Toys Industry Sporting Goods Industry contribute to product innovation and user experience primarily through their far-infrared emission and subtle influence on materials. When integrated into fabrics (e.g., sportswear, insoles) or composite materials (e.g., grips, equipment), the far-infrared rays emitted by tourmaline are believed to promote local blood circulation, potentially aiding in muscle recovery, reducing fatigue, and enhancing comfort during athletic activities. Their unique properties can also contribute to improved moisture management in textiles, enhancing breathability and quick-drying capabilities. Furthermore, incorporating tourmaline can impart subtle benefits to equipment performance, such as enhancing grip properties or damping vibrations in rackets or bats. These benefits offer manufacturers a distinct advantage in a highly competitive market, catering to athletes seeking natural ways to optimize performance and recovery.

Authoritative References

- Park, S. H., Park, S. S., & Kim, C. W. (2013). Effects of Tourmaline on Water Quality and Growth of Microalgae. Journal of Environmental Science and Engineering, 2(3), 169-174.

- Chen, Y., Zhou, S., Li, Y., & Chen, G. (2018). Review of Tourmaline Application in Water Treatment. Water Science and Technology, 78(1), 1-10.

- Ministry of Environmental Protection of the People's Republic of China. (2020). National Standards for Discharge of Pollutants for Municipal Wastewater Treatment Plants. (Referenced for context on discharge standards).

- ASTM International. (2017). ASTM F963 - 17 Standard Consumer Safety Specification for Toy Safety. (Referenced for toy safety standards).

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems – Requirements. (Referenced for quality management standards).