mica sheet design

Back to list

Feb . 13, 2025 00:57

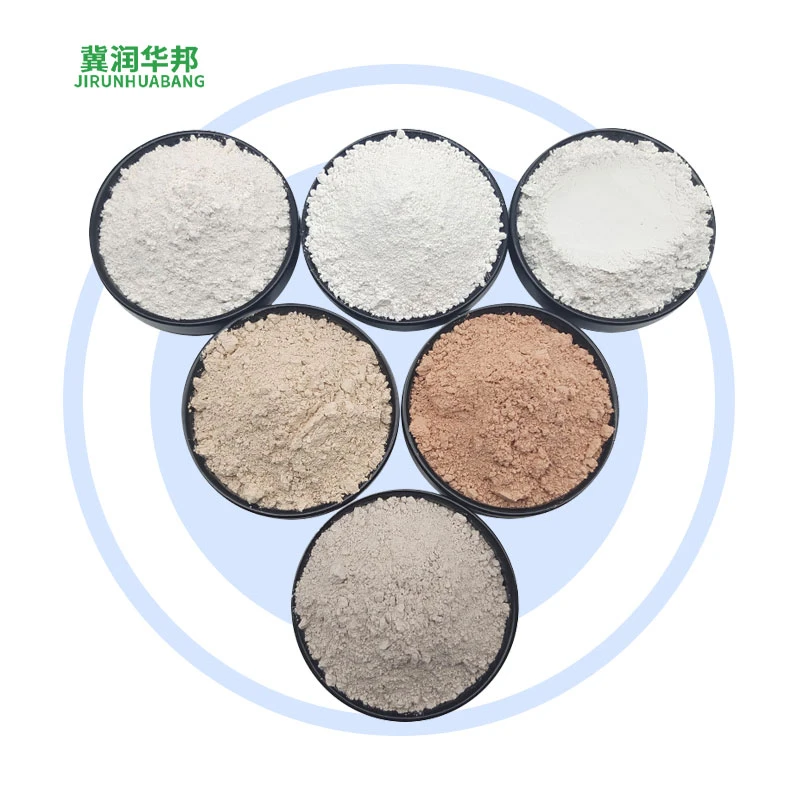

Mica sheet design represents a quintessential component in various industrial applications due to its unique thermodynamic properties and versatile applicability. As a material, mica offers unparalleled thermal and electrical insulation—qualities that empower industries ranging from electronics to construction to push the boundaries of innovation.

For professionals seeking to implement mica sheet design in their projects, trustworthiness is integral. In the complex supply chain of raw materials, ensuring the provenance and quality of mica is key to maintaining product standards. Reputable suppliers who adhere to stringent quality measures provide the assurance necessary for industries to leverage mica's remarkable properties effectively. This trust is built over years and validated through certifications and consistent performance metrics. Moreover, in the realm of sustainable development, mica's biodegradable nature positions it as a material of choice for eco-conscious businesses. Its environmental footprint is considerably lower compared to synthetic alternatives, aligning with global sustainability goals. This expertise in selecting materials that balance performance with ecological impact is becoming increasingly critical as industries strive to minimize their carbon footprints. The future of mica sheet design is poised for innovation, with advancements in nanotechnology promising even greater enhancements in performance metrics. By manipulating mica at the nanoscale, researchers aim to create ultra-thin, high-efficiency insulation materials, which could revolutionize existing applications and open new avenues in fields such as aerospace and renewable energy. In conclusion, the design of mica sheets is far more than a technical endeavor—it is a strategic integration of properties that redefine efficiency and sustainability. Professionals armed with a deep-seated understanding of mica's characteristics are well-equipped to harness its full potential, thereby advancing industry standards and fostering innovation. Whether through addressing electronic insulation challenges, contributing to robust architectural solutions, or supporting sustainable manufacturing processes, the role of mica sheet design in contemporary industry is as assured as it is transformative.

For professionals seeking to implement mica sheet design in their projects, trustworthiness is integral. In the complex supply chain of raw materials, ensuring the provenance and quality of mica is key to maintaining product standards. Reputable suppliers who adhere to stringent quality measures provide the assurance necessary for industries to leverage mica's remarkable properties effectively. This trust is built over years and validated through certifications and consistent performance metrics. Moreover, in the realm of sustainable development, mica's biodegradable nature positions it as a material of choice for eco-conscious businesses. Its environmental footprint is considerably lower compared to synthetic alternatives, aligning with global sustainability goals. This expertise in selecting materials that balance performance with ecological impact is becoming increasingly critical as industries strive to minimize their carbon footprints. The future of mica sheet design is poised for innovation, with advancements in nanotechnology promising even greater enhancements in performance metrics. By manipulating mica at the nanoscale, researchers aim to create ultra-thin, high-efficiency insulation materials, which could revolutionize existing applications and open new avenues in fields such as aerospace and renewable energy. In conclusion, the design of mica sheets is far more than a technical endeavor—it is a strategic integration of properties that redefine efficiency and sustainability. Professionals armed with a deep-seated understanding of mica's characteristics are well-equipped to harness its full potential, thereby advancing industry standards and fostering innovation. Whether through addressing electronic insulation challenges, contributing to robust architectural solutions, or supporting sustainable manufacturing processes, the role of mica sheet design in contemporary industry is as assured as it is transformative.

Share

Previous:

Next: