kaolin clay price per kg

Back to list

Feb . 07, 2025 03:27

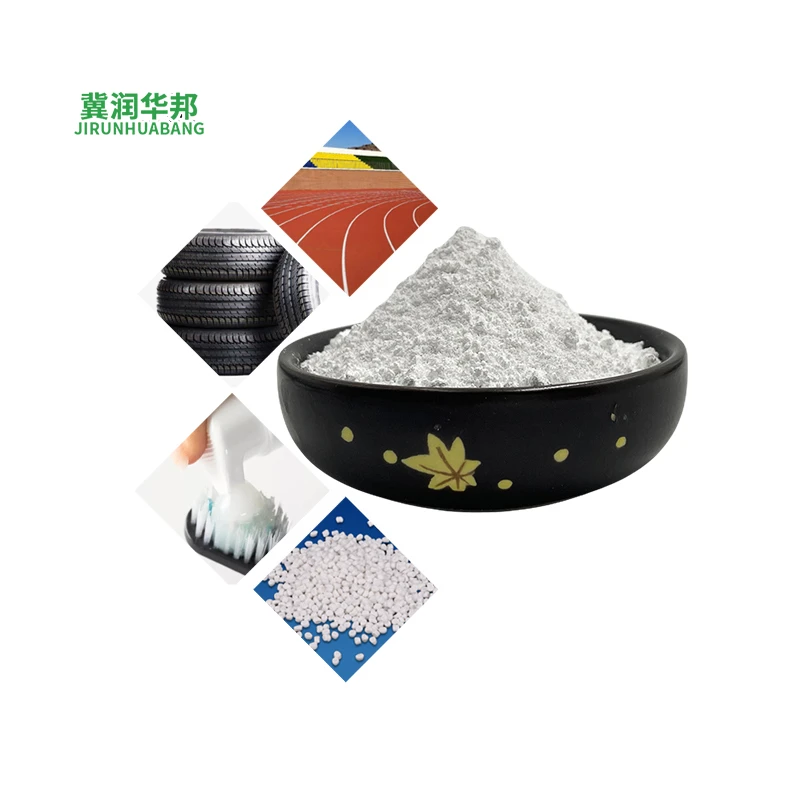

Kaolin clay, often referred to as China clay, is a naturally occurring mineral primarily composed of kaolinite. It is widely used in various industries due to its versatile properties. Over the years, the price per kilogram of kaolin clay has become a pertinent topic for manufacturers, suppliers, and consumers alike. Understanding the intricacies surrounding its cost can greatly benefit those involved in its trade.

A real-world example is the paper industry, where kaolin clay is employed as a filler to enhance the printability and appearance of paper products. Here, the consistency and quality of the clay significantly affect the manufacturing process, making premium kaolin a valuable asset. Companies investing in high-grade kaolin often witness better product outcomes, subsequently influencing their market share and profitability. In terms of expertise, industry analysts suggest that potential buyers closely monitor economic indicators that may influence kaolin prices, such as energy costs, technological advancements, and environmental regulations. Rising energy prices can lead to increased production costs, thereby inflating prices. Moreover, stringent environmental policies may necessitate cleaner technologies for kaolin extraction and processing, impacting the ultimate cost. Authoritative market reports from reputable organizations like the International Kaolin Association provide comprehensive insights into the industry’s pricing landscape. These reports often highlight trends concerning supply chain disruptions, global trade agreements, and competitive analysis, equipping stakeholders with the necessary data to make informed purchasing decisions. Building trust with suppliers is paramount for businesses relying on kaolin clay. Establishing long-term contracts with credible suppliers can ensure consistent pricing and supply, mitigating risks associated with market fluctuations. Partnering with suppliers known for ethical practices and sustainable extraction methods not only enhances trust but also aligns with the growing emphasis on corporate social responsibility. In conclusion, the price per kilogram of kaolin clay is influenced by a myriad of factors including extraction costs, geographic location, market demand, quality grades, and economic variables. For businesses seeking to leverage kaolin in their operations, understanding these dynamics is crucial. By staying informed and establishing strategic partnerships with trustworthy suppliers, companies can navigate the complexities of the kaolin market effectively, ensuring a stable and cost-efficient supply chain.

A real-world example is the paper industry, where kaolin clay is employed as a filler to enhance the printability and appearance of paper products. Here, the consistency and quality of the clay significantly affect the manufacturing process, making premium kaolin a valuable asset. Companies investing in high-grade kaolin often witness better product outcomes, subsequently influencing their market share and profitability. In terms of expertise, industry analysts suggest that potential buyers closely monitor economic indicators that may influence kaolin prices, such as energy costs, technological advancements, and environmental regulations. Rising energy prices can lead to increased production costs, thereby inflating prices. Moreover, stringent environmental policies may necessitate cleaner technologies for kaolin extraction and processing, impacting the ultimate cost. Authoritative market reports from reputable organizations like the International Kaolin Association provide comprehensive insights into the industry’s pricing landscape. These reports often highlight trends concerning supply chain disruptions, global trade agreements, and competitive analysis, equipping stakeholders with the necessary data to make informed purchasing decisions. Building trust with suppliers is paramount for businesses relying on kaolin clay. Establishing long-term contracts with credible suppliers can ensure consistent pricing and supply, mitigating risks associated with market fluctuations. Partnering with suppliers known for ethical practices and sustainable extraction methods not only enhances trust but also aligns with the growing emphasis on corporate social responsibility. In conclusion, the price per kilogram of kaolin clay is influenced by a myriad of factors including extraction costs, geographic location, market demand, quality grades, and economic variables. For businesses seeking to leverage kaolin in their operations, understanding these dynamics is crucial. By staying informed and establishing strategic partnerships with trustworthy suppliers, companies can navigate the complexities of the kaolin market effectively, ensuring a stable and cost-efficient supply chain.

Share

Previous: