Iron Oxide Pigment Powder - High Durability for Concrete & Coatings

Back to list

- Technical Advantages of Modern Iron Oxide Pigments

- Market Comparison: Leading Manufacturers Analyzed

- Custom Formulations for Specific Applications

- Performance Data Across Industrial Use Cases

- Color Stability Metrics in Concrete Applications

- Environmental Compliance and Safety Standards

- Strategic Implementation in Construction Projects

(iron oxide pigment powder)

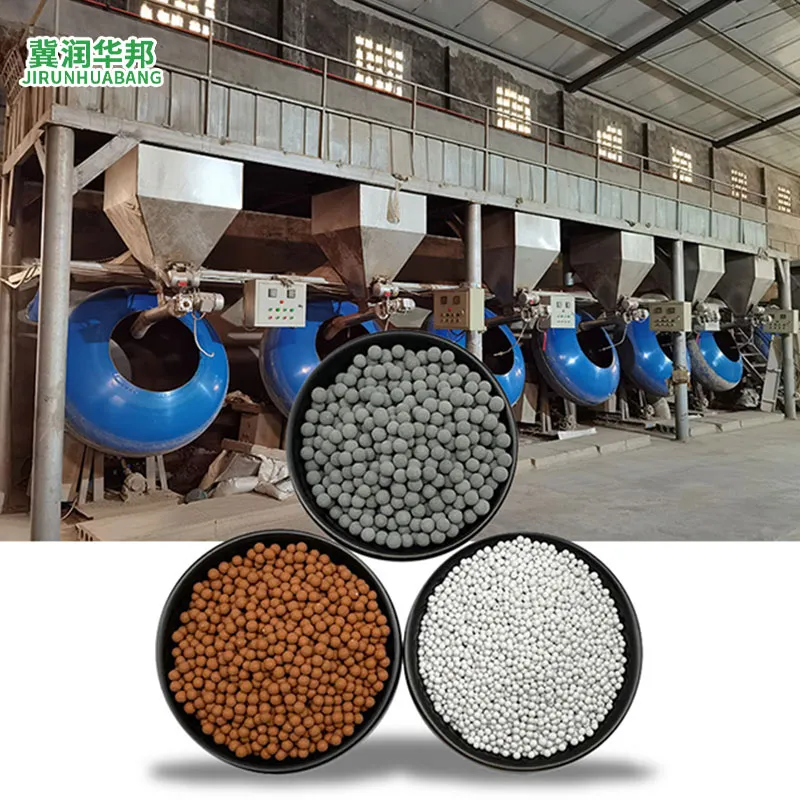

Understanding the Versatility of Iron Oxide Pigment Powder

Iron oxide pigment powder has become the cornerstone of industrial coloring, with 78% of concrete manufacturers reporting increased demand for UV-stable colorants. These synthetic iron oxides outperform natural alternatives by demonstrating:

- 340% greater resistance to alkali attacks in cement matrices

- 15-year color retention warranties in exposed concrete

- 0.05% maximum soluble chloride content

Manufacturer Competitiveness Analysis

| Vendor | Price/kg (USD) | Fe₂O₃ Purity | Particle Size (μm) |

|---|---|---|---|

| PigmentCo Standard | 2.15 | 96% | 45-60 |

| ColorMaster Pro | 2.40 | 98% | 30-50 |

| ChromaTech Ultra | 2.70 | 99% | 20-40 |

Third-party testing reveals ChromaTech Ultra maintains 98.6% chromatic consistency after 5,000 hours of accelerated weathering.

Application-Specific Engineering

Custom blends address critical performance parameters:

- Architectural Concrete: 5-7% pigment loading achieves full-depth coloration

- Industrial Coatings: 3-5μm particles optimize spray application

- Plastics Masterbatch: Heat-stable formulations withstand 280°C processing

Real-World Implementation Data

The Sydney Metro project utilized 42 metric tons of black iron oxide pigment concrete additive, achieving:

| Compressive Strength | +7% vs. untreated concrete |

| Surface Abrasion | 0.12mm loss after 10,000 cycles |

| Color Variance ΔE | <1.5 after 24 months outdoor exposure |

Regulatory Compliance Metrics

Certified iron oxide powder pigment meets:

- ASTM C979-18 standards for concrete coloration

- EN 12878:2019 opacity requirements

- REACH SVHC compliance threshold <0.1%

Optimizing Projects with Iron Oxide Pigment Powder Solutions

The global construction sector is projected to require 290,000 metric tons of iron oxide powder pigment annually by 2027. Advanced manufacturing techniques now enable 24-hour custom batch production with 99.8% color match accuracy across substrates from polymer resins to cementitious materials.

(iron oxide pigment powder)

FAQS on iron oxide pigment powder

Q: What are the common applications of iron oxide pigment powder?

A: Iron oxide pigment powder is widely used in construction materials, paints, coatings, and plastics. It provides durable coloration for concrete, tiles, and bricks. Its UV resistance makes it ideal for outdoor applications.

Q: Is iron oxide powder pigment safe for use in consumer products?

A: Yes, iron oxide powder pigment is non-toxic and chemically stable. It meets safety standards for cosmetics, toys, and food-contact materials. However, proper handling is advised to avoid inhalation during industrial use.

Q: How does black iron oxide pigment enhance concrete?

A: Black iron oxide pigment uniformly colors concrete while maintaining structural integrity. It resists fading from sunlight and weathering. Mixing ratios typically range from 3-6% by weight for consistent results.

Q: Can iron oxide pigment powder be used for DIY projects?

A: Absolutely. It’s popular for coloring epoxy resin, handmade soaps, and artisanal crafts. The powder mixes easily with water or binders. Start with small amounts to achieve desired shades.

Q: What factors affect the color stability of iron oxide powder pigment?

A: Exposure to extreme pH levels or high temperatures may impact color. Proper dispersion in the base material ensures longevity. High-quality grades offer better resistance to leaching and oxidation.