Durable Iron Oxide Pigments for Construction & Paint Industry

Back to list

In the dynamic worlds of construction and painting, the demand for materials that offer both aesthetic appeal and robust durability is ever-increasing. Central to achieving this balance are pigments – the very soul of color and the silent guardians of material longevity. Among these, iron oxide pigments stand out as an indispensable class, renowned for their exceptional stability, vast color range, and cost-effectiveness. This comprehensive guide will help you to Discover iron oxide pigments for construction industry painting industry, exploring their critical role, technical intricacies, manufacturing excellence, and diverse applications that shape our built environment.

Industry Trends: The Evolving Landscape of Construction and Painting Pigments

The global construction and painting industries are undergoing significant transformations, driven by sustainability initiatives, technological advancements, and evolving consumer preferences. Key trends influencing the demand for iron oxide pigments include:

- Sustainability Focus: A growing emphasis on green building materials and eco-friendly products means pigments must be non-toxic, free of heavy metals, and produced with minimal environmental impact. Iron oxide pigments, being naturally occurring or synthetically manufactured from abundant raw materials, align well with these goals.

- Durability and Performance: Structures and coatings are expected to withstand harsher weather conditions and prolonged exposure to UV radiation. This necessitates pigments that offer superior lightfastness, weather fastness, and chemical resistance, ensuring colors remain vibrant for decades.

- Aesthetic Versatility: Architects and designers increasingly seek a broader palette of colors and textures. Iron oxide pigments, available in reds, yellows, blacks, browns, and even some specialty shades, provide immense flexibility for creating diverse visual effects in concrete, paints, and coatings.

- Urbanization and Infrastructure Development: Rapid urbanization, particularly in developing economies, fuels massive infrastructure projects. This creates a sustained demand for durable and cost-effective coloring solutions for concrete, asphalt, and protective coatings.

- Digitalization in Color Matching: Advanced spectrophotometers and color formulation software are enhancing precision in color matching, demanding pigments with consistent color properties and dispersibility.

Understanding these trends is crucial to appreciating why iron oxide pigments remain a cornerstone in these industries and how they continue to adapt to new challenges and opportunities to help you Discover iron oxide pigments for construction industry painting industry effectively.

Technical Parameters and Properties of Iron Oxide Pigments

To truly Discover iron oxide pigments for construction industry painting industry, one must delve into their technical specifications. Iron oxide pigments (CI Pigment Red 101, CI Pigment Yellow 42, CI Pigment Black 11, etc.) are inorganic compounds known for their exceptional physical and chemical properties. These properties are critical for their performance in various applications. Below is a comprehensive table detailing the key parameters:

Key Technical Specifications of Iron Oxide Pigments

| Parameter | Description | Typical Value Range (Red/Yellow) | Significance |

|---|---|---|---|

| Chemical Composition | Primarily Iron(III) Oxide (Fe₂O₃) for reds, Iron(III) Hydroxide Oxide (FeOOH) for yellows, Magnetite (Fe₃O₄) for blacks. | Fe₂O₃ > 95% | Determines color, stability, and chemical inertness. High purity minimizes impurities. |

| Color Index (CI No.) | International classification for pigments. E.g., Red 101, Yellow 42, Black 11. | PR101, PY42, PBk11 | Standardized identification for specific pigment types and hues. |

| Particle Size (µm) | Average diameter of pigment particles. Influences tinting strength, opacity, and dispersion. | 0.1 - 5.0 µm | Finer particles generally mean higher tinting strength and better hiding power. Affects gloss and rheology. |

| Tinting Strength (%) | The ability of a pigment to impart color when mixed with a white pigment. Higher value means more intense color. | 95-105% (relative) | Indicates cost-effectiveness; less pigment needed to achieve desired color. |

| Oil Absorption (g/100g) | Amount of linseed oil required to form a coherent paste with 100g of pigment. | 20 - 60 g/100g | Affects rheology, gloss, and binder demand in coatings. Lower values are generally preferred. |

| Lightfastness (1-8 Scale) | Resistance to fading or discoloration when exposed to light, based on Blue Wool Scale. 8 is excellent. | 7-8 | Crucial for outdoor applications, ensuring long-term color stability. |

| Weather Fastness (1-5 Scale) | Resistance to degradation from outdoor elements (rain, humidity, temperature changes). 5 is excellent. | 4-5 | Ensures durability and color retention in harsh environmental conditions. |

| Heat Stability (°C) | Maximum temperature the pigment can withstand without significant color change or decomposition. | 180°C - 800°C+ | Important for high-temperature processes like plastic extrusion, asphalt, or cement curing. |

| pH Value | Acidity or alkalinity of the pigment slurry. | 6 - 8 (neutral) | Influences compatibility with various binders and systems, preventing flocculation or degradation. |

| Moisture Content (%) | Percentage of water present in the pigment. | Low moisture is critical for storage stability and dispersion properties. | |

| Water Soluble Content (%) | Amount of soluble salts that can leach out. | Low content prevents efflorescence in concrete and corrosion in metal coatings. |

These parameters are meticulously controlled during manufacturing to ensure consistent quality and performance across various batches and applications. Our commitment to meeting and exceeding industry benchmarks like ISO standards (e.g., ISO 1248-1 for pigments for paints and related products) ensures our iron oxide pigments deliver superior results.

Application Scenarios: Where Iron Oxide Pigments Shine

The versatility of iron oxide pigments makes them indispensable across a multitude of applications in both the construction and painting industries. When you Discover iron oxide pigments for construction industry painting industry, you find their footprint everywhere from foundational elements to decorative finishes:

- Concrete and Masonry Products: This is a primary application. Iron oxides are used to color concrete pavers, roof tiles, precast concrete elements, ready-mix concrete, mortar, stucco, and grout. Their excellent alkali resistance and weather fastness ensure that the vibrant colors endure for the lifetime of the structure. Examples include colored driveways, patios, architectural facades, and permeable pavements.

- Paints and Coatings: In both decorative and industrial paints, iron oxides provide durable, opaque, and cost-effective coloration.

- Architectural Coatings: For interior and exterior wall paints, providing a vast palette of earth tones.

- Industrial Coatings: Used in anti-corrosive primers and topcoats for metal structures (bridges, pipelines, machinery), offering excellent barrier protection and UV stability.

- Road Marking Paints: For highly durable and visible road markings.

- Plastics and Rubber: Iron oxide pigments are incorporated into plastics for various applications like PVC pipes, plastic window frames, garden furniture, and automotive parts, providing consistent color and UV stability without affecting material integrity. In rubber products, they are used for tires, flooring, and other molded goods.

- Asphalt and Bitumen: Used to color asphalt for decorative purposes, such as bike paths, sports courts, or aesthetically pleasing road surfaces, enhancing urban landscapes.

- Ceramics and Tiles: Integrated into ceramic bodies and glazes to produce various shades, particularly reddish-browns and blacks, that are stable under high firing temperatures.

- Artist's Colors: Due to their permanence and natural appeal, iron oxides are popular in oil paints, watercolors, and acrylics.

These diverse applications underscore the critical role these pigments play in delivering both aesthetic value and long-term performance across various industries, emphasizing the importance to Discover iron oxide pigments for construction industry painting industry for specific needs.

Technical Advantages and Benefits

The superior performance of iron oxide pigments stems from several inherent technical advantages that make them a preferred choice for many applications:

- Exceptional Durability and Permanence: Iron oxides are incredibly stable under various environmental conditions. They exhibit outstanding lightfastness and weather fastness, meaning they resist fading, chalking, and degradation when exposed to sunlight, rain, and temperature fluctuations. This ensures that the color remains vibrant and true for decades, significantly reducing maintenance and recoating cycles.

- Chemical Resistance: These pigments are highly resistant to acids, alkalis, and solvents, making them ideal for use in harsh chemical environments, such as in concrete (high alkalinity) or industrial coatings. This chemical inertness prevents color shift or degradation due to chemical interactions.

- Non-Toxicity and Eco-Friendliness: Unlike some organic or heavy-metal-based pigments, iron oxides are non-toxic, non-carcinogenic, and environmentally benign. They meet stringent international regulations, including REACH and RoHS, making them safe for a wide range of applications, including those in residential and public spaces. This aligns perfectly with the growing demand for sustainable building materials.

- High Tinting Strength and Opacity: Even at low concentrations, iron oxide pigments deliver strong, vibrant colors and excellent hiding power. This leads to cost-effectiveness as less pigment is required to achieve the desired color intensity and opacity in formulations.

- Thermal Stability: Many iron oxide pigments can withstand high temperatures without decomposing or changing color, making them suitable for processes like concrete curing, plastic extrusion, and certain high-temperature coatings.

- Cost-Effectiveness: Relative to their performance and durability, iron oxide pigments are generally more economical than many organic or complex inorganic pigments, offering a superior cost-to-performance ratio.

- UV Resistance: Beyond just color stability, iron oxides act as effective UV absorbers, protecting the binder or substrate from UV degradation, thereby extending the lifespan of paints, coatings, and plastic products.

These advantages collectively highlight why iron oxide pigments are a reliable and high-performing choice for professionals looking to Discover iron oxide pigments for construction industry painting industry.

Manufacturing Process of Iron Oxide Pigments

The production of high-quality iron oxide pigments involves sophisticated chemical processes designed to control particle size, shape, and purity, which directly impact color, tinting strength, and dispersion properties. While specific methods vary (e.g., Laux process, Penniman process, precipitation, calcination), the general workflow ensures consistent product excellence. Here's a simplified illustration of the typical manufacturing process, enabling you to better Discover iron oxide pigments for construction industry painting industry from a production standpoint:

1. Raw Material Preparation

Begins with high-purity iron scraps, iron salts (like ferrous sulfate), and alkalis (e.g., sodium hydroxide, ammonia). Strict quality control ensures consistency.

2. Reaction/Precipitation

Iron salts react with alkalis under controlled temperature and pH to precipitate iron oxide/hydroxide particles. Precise control of conditions determines particle morphology and size, impacting color hue and intensity.

3. Filtration & Washing

The precipitated pigment slurry is filtered to separate solid pigment from the liquid. Thorough washing removes soluble salts and impurities, preventing efflorescence and ensuring chemical stability.

4. Drying & Milling

The wet pigment cake is dried in large ovens. Subsequently, it undergoes milling (micronization) to break down agglomerates and achieve the desired fine particle size for optimal dispersion and tinting strength.

5. Calcination (for Reds/Blacks)

For red and black iron oxides, the dried yellow pigment (goethite) or black (magnetite) is calcined (heated to high temperatures) to convert it into stable red hematite or maintain black magnetite, enhancing heat and lightfastness.

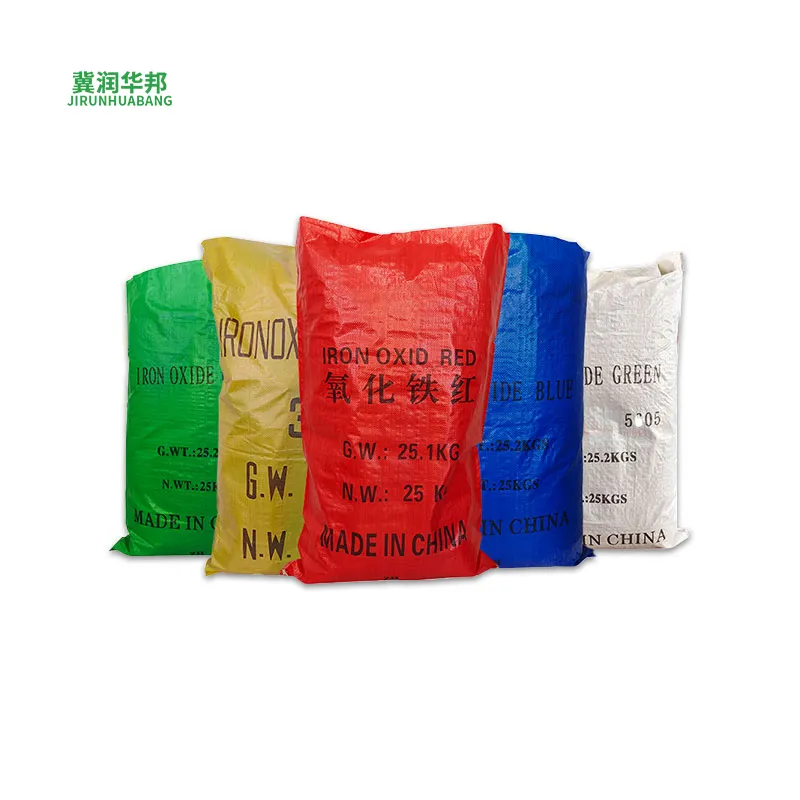

6. Quality Control & Packaging

Every batch undergoes rigorous quality checks for color consistency, tinting strength, oil absorption, particle size, moisture, and chemical purity, adhering to international standards (e.g., ISO 9001, ASTM D3724). Finally, the finished product is packaged into bags or container111s.

(Note: For a visual representation, imagine a flow chart with arrows connecting these steps, or a short video illustrating the key stages like mixing, filtration, and drying in a factory setting. A link to such media could be Watch our manufacturing process or an embedded diagram.)

Our manufacturing process emphasizes precision engineering and stringent quality control at every stage. We utilize advanced reactors, filtration systems, and micronization equipment to produce pigments with consistent properties, ensuring high purity, optimal particle distribution, and superior performance in end applications. Adherence to standards like ISO 9001 for quality management and ISO 14001 for environmental management underpins our commitment to excellence and sustainability.

Manufacturer Comparison: Choosing Your Pigment Partner

When seeking to Discover iron oxide pigments for construction industry painting industry, selecting the right manufacturer is as crucial as understanding the product itself. The market offers various suppliers, but a discerning eye can identify key differentiators:

- R&D and Innovation Capabilities: Leading manufacturers invest heavily in research and development to create new shades, improve pigment dispersion, and enhance performance characteristics (e.g., higher tinting strength, better heat stability). They are at the forefront of developing sustainable pigment solutions.

- Quality Control and Certifications: A reputable manufacturer will have robust quality management systems (like ISO 9001) and conduct extensive testing (e.g., spectrophotometry for color, laser diffraction for particle size, accelerated weathering tests). Third-party certifications (e.g., ASTM, DIN) vouch for product consistency and reliability.

- Production Capacity and Supply Chain Reliability: The ability to meet large-scale demands and ensure timely delivery is vital for construction and painting projects. A strong global supply chain and efficient logistics are indicators of reliability.

- Technical Support and Customer Service: Expert technical support can assist with pigment selection, formulation advice, troubleshooting, and custom color matching. Responsiveness and a client-centric approach are hallmarks of a valuable partner.

- Environmental and Safety Compliance: Adherence to environmental regulations (like REACH, RoHS, LEED compatibility) and a strong commitment to worker safety and sustainable practices are increasingly important considerations for responsible sourcing.

- Customization Capabilities: The ability to develop tailor-made pigment solutions for unique project requirements (specific shades, particular dispersion needs, enhanced properties for niche applications) sets a manufacturer apart.

- Industry Experience and Reputation: A long-standing presence in the market, positive customer testimonials, and a portfolio of successful application cases speak volumes about a manufacturer's expertise and trustworthiness.

We pride ourselves on excelling in all these areas, combining decades of experience with cutting-edge technology to deliver superior iron oxide pigments and unparalleled customer support, fostering trust and long-term partnerships.

Custom Solutions for Unique Requirements

The diverse needs of the construction and painting industries often go beyond standard product offerings. Recognizing this, our approach to helping you Discover iron oxide pigments for construction industry painting industry extends to providing highly customized solutions:

- Precise Color Matching: Utilizing advanced spectrophotometric equipment and experienced colorists, we can match almost any desired hue, ensuring seamless integration with existing designs or brand guidelines. This is particularly valuable for architectural projects requiring specific aesthetic outcomes.

- Tailored Particle Size Distribution: Depending on the application (e.g., high-gloss paints vs. textured concrete), we can optimize particle size and distribution to improve dispersion, rheology, gloss, or hiding power.

- Enhanced Performance Properties: For specific demanding environments, we can develop pigments with enhanced features such as improved heat stability for high-temperature processes, increased dispersibility for automated dosing systems, or specialized surface treatments for better compatibility with challenging binder systems.

- Application-Specific Formulations: Whether it's for dry mix mortars, water-based paints, solvent-based coatings, or plastic masterbatches, we can recommend and supply pigments optimized for your specific formulation and manufacturing process, ensuring maximum efficiency and performance.

- Technical Consultation and Support: Our team of technical experts collaborates closely with clients, providing in-depth consultation on pigment selection, dosage recommendations, and troubleshooting to overcome formulation challenges and achieve optimal results.

This commitment to customization ensures that our clients receive not just a product, but a precise solution perfectly aligned with their project's unique demands, making us a true partner in your success.

Application Cases and Success Stories

Our high-performance iron oxide pigments have been instrumental in countless projects globally, demonstrating their reliability and versatility across various applications. Here are a few illustrative examples showcasing how our clients have leveraged our products to achieve outstanding results when they Discover iron oxide pigments for construction industry painting industry:

Case Study 1: Architectural Concrete Facade for a Commercial Complex

Challenge: A prominent architectural firm required a consistent, durable, and aesthetically pleasing reddish-brown hue for the precast concrete facade of a new commercial complex. The color needed to withstand intense UV radiation and varied weather conditions while maintaining its vibrancy over decades.

Solution: We provided a custom blend of our high-quality synthetic red and black iron oxide pigments, specifically engineered for concrete applications. Our technical team collaborated with the precast manufacturer to optimize the dispersion and dosage, ensuring perfect color uniformity across thousands of panels.

Result: The facade achieved a stunning, deep reddish-brown tone that has remained consistent and vibrant since its completion five years ago. Accelerated weathering tests conducted by an independent lab confirmed superior lightfastness (Grade 8 on Blue Wool Scale) and excellent resistance to efflorescence, contributing significantly to the building's striking visual appeal and long-term value.

Case Study 2: High-Performance Industrial Anti-Corrosion Coating

Challenge: A leading manufacturer of industrial machinery needed a highly durable and corrosion-resistant coating for equipment exposed to harsh industrial environments, including chemical spills and extreme temperatures. The coating also required an aesthetically pleasing black finish.

Solution: We supplied a specialized grade of our synthetic black iron oxide pigment (Fe₃O₄), known for its exceptional chemical and thermal stability, along with its excellent opacity. This pigment was incorporated into a two-part epoxy coating system.

Result: The resulting coating provided superior corrosion protection and maintained its deep black color even after prolonged exposure to aggressive chemicals and high temperatures. Customer feedback highlighted significantly extended service life of their machinery, leading to reduced maintenance costs and enhanced product reputation. The coating passed ASTM B117 salt spray tests for over 2000 hours, far exceeding industry standards.

Case Study 3: Sustainable Colored Pavers for Urban Landscaping

Challenge: A municipal project aimed to revitalize public parks and pedestrian pathways with sustainable, aesthetically appealing colored concrete pavers that could withstand heavy foot traffic and varied climatic conditions.

Solution: We provided our eco-friendly yellow and red iron oxide pigments, certified for low environmental impact and high durability. Our pigments ensured batch-to-batch color consistency for the paver manufacturer, crucial for large-scale landscaping projects.

Result: The parks now feature beautifully colored pavers that blend seamlessly with the natural environment, providing long-lasting vibrancy and wear resistance. The project was lauded for its sustainable material choices and enhanced urban aesthetics, with the pavers showing no sign of fading or degradation after years of use.

These cases exemplify our commitment to delivering high-quality, reliable, and versatile iron oxide pigments that contribute to the success and sustainability of diverse projects in the construction and painting sectors. Our extensive experience and technical expertise make us an ideal partner as you seek to Discover iron oxide pigments for construction industry painting industry for your next endeavor.

Guaranteed Quality

All our products adhere to strict international quality standards, including ISO 9001, ensuring consistent performance and reliability.

Global Reach & Delivery

With an efficient global logistics network, we ensure timely and reliable delivery of your pigment orders worldwide.

Expert Technical Support

Our team of experienced chemists and engineers provides comprehensive technical assistance, from product selection to application optimization.

Custom Formulation

We offer tailored pigment solutions and custom color matching to meet your precise project specifications and aesthetic demands.

Sustainable Practices

Committed to environmental responsibility, our manufacturing processes prioritize energy efficiency and waste reduction, aligning with industry green initiatives.

Decades of Experience

Leveraging over 20 years of industry leadership, we bring unparalleled expertise and proven reliability to every partnership.

Frequently Asked Questions (FAQs) about Iron Oxide Pigments

Q1: What is the primary difference between natural and synthetic iron oxide pigments?

A1: Natural iron oxide pigments are mined from natural mineral deposits and then purified and ground. Their color and properties can vary depending on the source. Synthetic iron oxides, on the other hand, are chemically manufactured under controlled conditions, allowing for greater purity, more consistent color, higher tinting strength, and better control over particle size and shape. This consistency makes synthetic pigments generally preferred for industrial applications.

Q2: Are iron oxide pigments safe for environmental applications, like coloring playgrounds or water features?

A2: Yes, generally. High-quality synthetic iron oxide pigments are non-toxic, lead-free, and heavy metal-free, making them environmentally benign. They are widely used in applications like playgrounds, walking paths, and architectural concrete without posing environmental or health risks. Always check specific product certifications (e.g., meeting EN 71-3 for toy safety) for critical applications.

Q3: How does particle size affect the performance of iron oxide pigments?

A3: Particle size is crucial. Finer particles (smaller size) typically result in higher tinting strength, better hiding power (opacity), and smoother surface finishes. However, very fine particles can increase oil absorption and may be harder to disperse. Larger particles might offer better durability in certain high-wear applications. Optimizing particle size distribution is key for specific applications, influencing gloss, rheology, and dispersibility.

Q4: What is "lightfastness" and why is it important for construction and painting?

A4: Lightfastness refers to a pigment's ability to resist fading or discoloration when exposed to light, especially UV radiation. It is measured on a scale (e.g., Blue Wool Scale, 1-8, with 8 being excellent). For construction materials and paints exposed outdoors, excellent lightfastness is paramount to ensure that the color of concrete, roof tiles, or exterior paints remains vibrant and true for decades, preventing premature degradation and costly recoating.

Q5: Can iron oxide pigments be used in high-alkaline environments like fresh concrete?

A5: Absolutely. One of the significant advantages of iron oxide pigments is their excellent alkali resistance. They are highly stable in high-pH environments, making them ideal for coloring cementitious materials such as concrete, mortar, and stucco, where other pigment types might degrade or fade.

Q6: What is the typical delivery lead time for bulk orders of iron oxide pigments?

A6: Our standard delivery lead time for bulk orders typically ranges from 7 to 14 business days, depending on the specific product, quantity, and destination. For urgent or highly customized orders, we work closely with clients to accommodate specific timelines. We maintain robust inventory levels and efficient logistics to minimize delays.

Q7: Do you provide technical support for pigment dispersion and formulation?

A7: Yes, comprehensive technical support is a cornerstone of our service. Our experienced R&D team and application specialists are available to provide guidance on pigment selection, optimal dispersion techniques, dosage recommendations, and troubleshooting any formulation challenges you might encounter. We aim to ensure you achieve the best possible performance from our pigments.

References and Further Reading:

For more in-depth information, consider exploring these authoritative resources:

- ASTM D3724 - Standard Specification for Synthetic Red Iron Oxide Pigment: https://www.astm.org/d3724-18.html

- European Chemicals Agency (ECHA) - Information on Iron Oxides: https://echa.europa.eu/substance-information/-/dissemination/registered-substances/100.029.020

- "Pigments for Paints" by W. Herbst and K. Hunger (Wiley-VCH): A comprehensive resource on pigment chemistry and application. (Note: Specific link to book might vary based on publisher/retailer)

- "Durability and Aesthetics: The Role of Pigments in Colored Concrete," Concrete Construction Magazine: https://www.concreteconstruction.net/how-to/materials/durability-and-aesthetics-the-role-of-pigments-in-colored-concrete_o