density of wollastonite

Back to list

Jan . 13, 2025 11:05

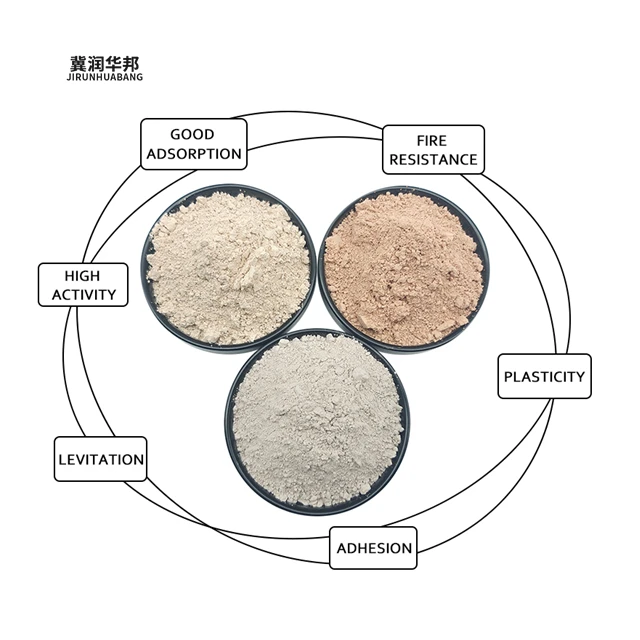

Wollastonite, a calcium silicate mineral, has emerged as a critical material in a variety of industrial applications due to its unique properties, including its density. With a typical density ranging from 2.8 to 2.9 grams per cubic centimeter, wollastonite's low-density profile contributes significantly to its functional versatility, making it an indispensable component in product manufacturing and innovation.

Wollastonite’s low-density characteristic also extends benefits to the paints and coatings sector. By serving as a functional additive, it enhances the formulation of environmentally friendly coatings with improved adhesion and weatherability. Products with wollastonite exhibit superior surface finishes, resistance to wear, and longevity, translating to lower maintenance costs and increased consumer trust. Collaborative research continues to explore the potential of wollastonite's density in emerging applications. Innovations in 3D printing, for example, leverage its material properties to create lightweight, yet durable, components with precision and efficiency. The mineral's ability to blend with other materials presents industry leaders with opportunities to explore uncharted territories in product development. As more sectors discover the multifunctionality of wollastonite, transparency and trustworthiness in sourcing and material specification become paramount. Industry experts emphasize the importance of rigorous quality controls and ethical mining practices, ensuring that the supply chain supports both safety and environmental standards. Leading manufacturers are thus committed to fostering sustainability, assuring end-users of the authenticity and reliability of wollastonite-enhanced products. In conclusion, the density of wollastonite underpins its widespread adoption across diverse industries. Its ability to contribute to lightweight, robust, and sustainable products positions it as a mineral of choice in the quest for innovative solutions. With its continued research and application, wollastonite remains integral to meeting the evolving needs of modern manufacturing, accentuating its role as both a practical and authoritative material in the global market.

Wollastonite’s low-density characteristic also extends benefits to the paints and coatings sector. By serving as a functional additive, it enhances the formulation of environmentally friendly coatings with improved adhesion and weatherability. Products with wollastonite exhibit superior surface finishes, resistance to wear, and longevity, translating to lower maintenance costs and increased consumer trust. Collaborative research continues to explore the potential of wollastonite's density in emerging applications. Innovations in 3D printing, for example, leverage its material properties to create lightweight, yet durable, components with precision and efficiency. The mineral's ability to blend with other materials presents industry leaders with opportunities to explore uncharted territories in product development. As more sectors discover the multifunctionality of wollastonite, transparency and trustworthiness in sourcing and material specification become paramount. Industry experts emphasize the importance of rigorous quality controls and ethical mining practices, ensuring that the supply chain supports both safety and environmental standards. Leading manufacturers are thus committed to fostering sustainability, assuring end-users of the authenticity and reliability of wollastonite-enhanced products. In conclusion, the density of wollastonite underpins its widespread adoption across diverse industries. Its ability to contribute to lightweight, robust, and sustainable products positions it as a mineral of choice in the quest for innovative solutions. With its continued research and application, wollastonite remains integral to meeting the evolving needs of modern manufacturing, accentuating its role as both a practical and authoritative material in the global market.

Share

Previous: