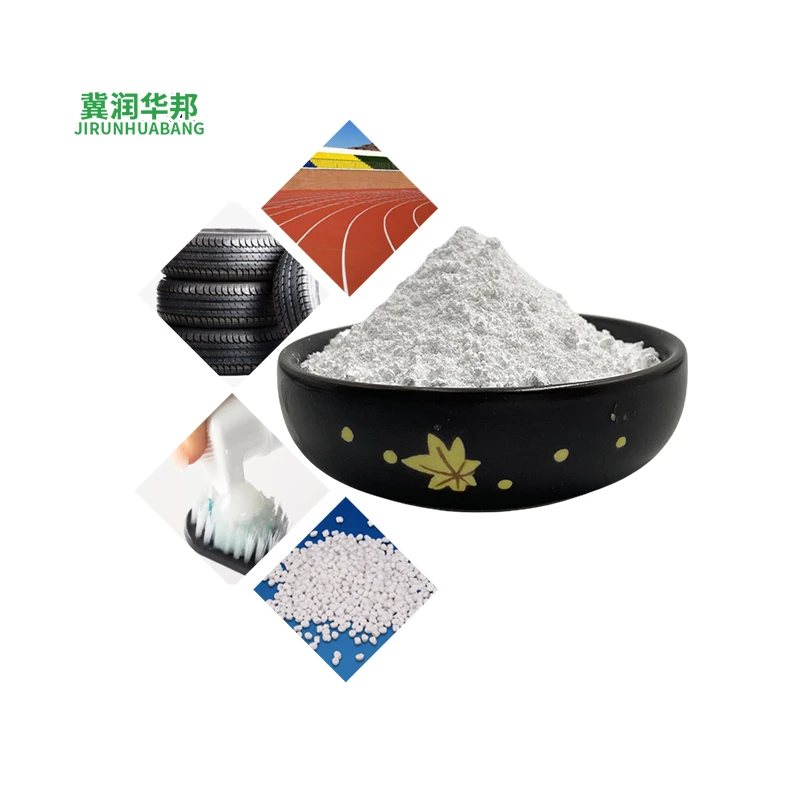

Runhuabang Limestone powder plastic rubber additives feed heavy calcium powder

Back to list

Feb . 13, 2025 03:14

The mica sheet manufacturing process is a sophisticated journey that emphasizes precision and quality. Mica, a mineral renowned for its excellent thermal and electrical insulating properties, undergoes several meticulous procedures to transform into sheets utilized across various industries including electronics, automotive, and construction.

Annealing is another fundamental aspect of mica sheet production. This controlled heating process stabilizes the sheets, releasing internal stresses and strengthening structural integrity. Understanding the precise temperatures and durations for this heat treatment demands unparalleled expertise, illustrating the fine line between a functional product and one that's susceptible to failure. Quality control is infused throughout the mica sheet manufacturing process. Routine inspections ensure consistency across batches. From visual inspection to advanced spectrometric analysis, each sheet is carefully assessed for defects like surface irregularities or thickness variations. Random sampling tactics are often employed to reinforce confidence, creating a trusted batch of mica sheets for commercial use. The final stages involve packaging and distribution but not before another round of quality checks. Proper packaging is critical to preserving the mica sheets' properties during transit, protecting them from physical damage. Companies with authoritative experience understand the importance of providing clients with instructional guidelines on handling and installation, ensuring the end-use capitalizes on the product's insulating potential. Sustainability plays a growing role in mica sheet manufacturing. Several leading producers have begun integrating eco-friendly practices, including the use of biodegradable cleaning agents and recycling water during the washing phase. This initiative aligns with global trends towards environmental responsibility, reinforcing the industry's trustworthiness and commitment to future generations. Overall, the mica sheet manufacturing process is a blend of expert technical skills, precise technology, and unyielding quality standards. It's this commitment to excellence that solidifies a manufacturer’s reputation in the competitive industrial materials market, providing customers with dependable products that meet exacting specifications. As industries continue to evolve, mica suppliers leveraging their experience, expertise, and authoritative knowledge will remain vital contributors to advancing technological innovations.

Annealing is another fundamental aspect of mica sheet production. This controlled heating process stabilizes the sheets, releasing internal stresses and strengthening structural integrity. Understanding the precise temperatures and durations for this heat treatment demands unparalleled expertise, illustrating the fine line between a functional product and one that's susceptible to failure. Quality control is infused throughout the mica sheet manufacturing process. Routine inspections ensure consistency across batches. From visual inspection to advanced spectrometric analysis, each sheet is carefully assessed for defects like surface irregularities or thickness variations. Random sampling tactics are often employed to reinforce confidence, creating a trusted batch of mica sheets for commercial use. The final stages involve packaging and distribution but not before another round of quality checks. Proper packaging is critical to preserving the mica sheets' properties during transit, protecting them from physical damage. Companies with authoritative experience understand the importance of providing clients with instructional guidelines on handling and installation, ensuring the end-use capitalizes on the product's insulating potential. Sustainability plays a growing role in mica sheet manufacturing. Several leading producers have begun integrating eco-friendly practices, including the use of biodegradable cleaning agents and recycling water during the washing phase. This initiative aligns with global trends towards environmental responsibility, reinforcing the industry's trustworthiness and commitment to future generations. Overall, the mica sheet manufacturing process is a blend of expert technical skills, precise technology, and unyielding quality standards. It's this commitment to excellence that solidifies a manufacturer’s reputation in the competitive industrial materials market, providing customers with dependable products that meet exacting specifications. As industries continue to evolve, mica suppliers leveraging their experience, expertise, and authoritative knowledge will remain vital contributors to advancing technological innovations.

Share

Previous: