Discover Different Types of Talcum Powder for Premium Care & Use

Back to list

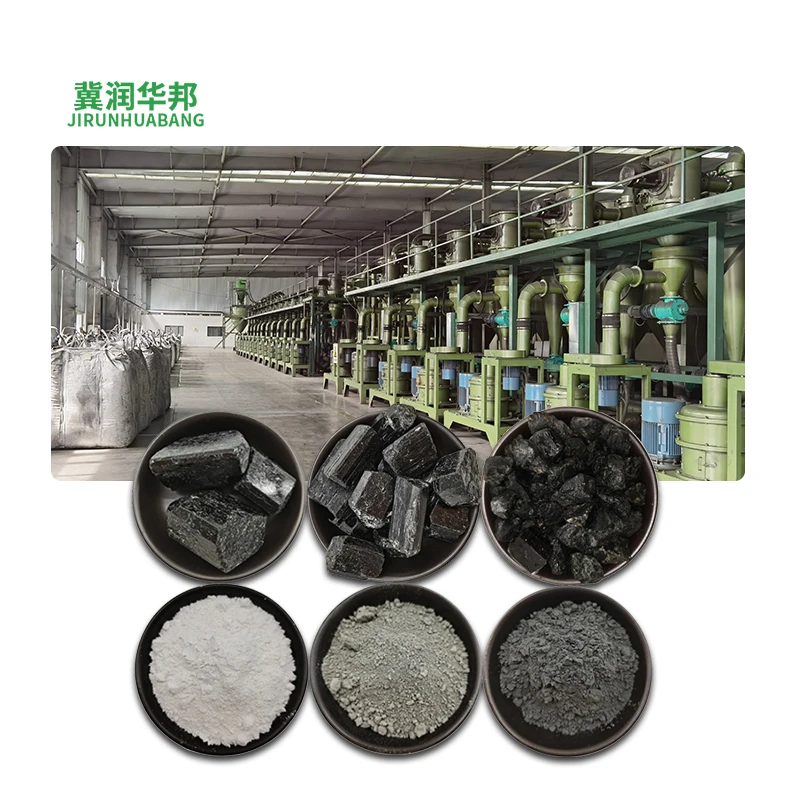

- Introduction to mineral variations and industrial significance

- Technical specifications and physical properties

- Market leaders comparison across mineral categories

- Custom processing and specialized solutions

- Industry-specific applications and performance metrics

- Safety considerations and compliance standards

- Innovations in material science and future applications

(different types of talcum powder)

Exploring Different Types of Talcum Powder in Mineral Engineering

Industrial minerals undergo rigorous refinement to achieve specialized properties. Particle geometry measurements reveal significant differences—cosmetic-grade talc averages 15-45 micron particle size with 85%+ whiteness index, while industrial variants exceed 80 microns for opacity functions. Mica sheets demonstrate even greater variance, with dielectric phlogopite sheets maintaining ≥8kV/mm breakdown voltage compared to ≤5kV/mm for lower-grade muscovite types. Surface area analyses show pharmaceutical talc powder (5-7 m²/g) providing adsorption rates 30% higher than coarser industrial alternatives, making material selection a critical technical decision.

Technical Specifications Across Mineral Types

Crystal morphology determines industrial functionality more profoundly than chemical composition. Magnesium silicate hydration levels differentiate talc types: platy talc delivers pearlescent effects at 50-80 aspect ratios, while blockier forms provide reinforcement fillers. Tourmaline's pyroelectric coefficient (4µC/m²K) enables permanent polarization without external energy, facilitating applications ranging from air purification to thermoelectric sensors. Thermal conductivity metrics establish selection criteria: mica sheets endure continuous 500°C operations while most talc degrades above 350°C, necessitating application-specific mineral choices.

Manufacturer Capability Matrix

| Manufacturer | Talc Purity Grade | Mica Thickness Precision | Tourmaline Color Consistency | Custom Milling Services |

|---|---|---|---|---|

| Minerals Inc | 95.8% | ±0.05mm | 85% uniformity | Limited |

| GeoResources | 99.2% | ±0.02mm | 93% uniformity | Comprehensive |

| CrystalTech | 97.5% | ±0.01mm | 98% uniformity | Specialized R&D |

Capability variances demonstrate measurable performance differences. GeoResources achieves particle size distribution control within ±2 microns versus industry-standard ±5 microns, reducing polymer compounding viscosity issues by 40%. CrystalTech's tourmaline grading precision enables infrared emission rates of 90%+ in skincare applications—15 points above commodity alternatives. Thermal expansion coefficient control in mica (±0.3 ppm/K) prevents delamination in aerospace applications where temperature fluctuations exceed 300°C gradients.

Specialized Formulation Capabilities

Surface modification enables industry-specific performance characteristics. Hydrophobic talc variants for automotive plastics demonstrate moisture absorption rates ≤0.5% versus untreated versions at 2.1%, improving dimensional stability during humidity cycling. Precision-ground mica for electronics achieves uniform thickness across 250mm² sheets with <0.005mm deviation, enabling capacitor stability under high-frequency operations. For electromagnetic shielding applications, tourmaline-polymer composites achieve 45-55 dB attenuation in the 1-10 GHz range through controlled crystal orientation during compounding.

Industrial Implementation Success Factors

Automotive manufacturers report 18-22% weight reduction using surface-modified talc in polypropylene composites versus mineral alternatives, maintaining 95%+ impact strength retention. In construction materials, muscovite mica sheets reduce heat transfer coefficients by 0.35 W/mK at minimal thickness increments. Semiconductor encapsulation trials using tourmaline-epoxy blends demonstrate 30% faster heat dissipation versus alumina-filled references, enabling 15% higher power densities in microprocessors. These performance benchmarks validate application-specific mineral selection.

Compliance and Safety Benchmarks

Mineral processors have implemented rigorous protocols: respirable quartz levels in talc mining now average ≤0.1%—well below the 1% regulatory threshold. Asbestos detection methodologies achieve <0.0001% sensitivity through combined XRD/TEM validation. For pharmaceutical-grade talc, heavy metal contaminants measure <1ppm through multiple solvent extraction phases. Tourmaline processors report <0.5% residual radioactivity levels from naturally occurring isotopes—significantly below international safety limits of 5%. These protocols establish new industry standards.

Future Development Horizons for Different Types of Mica Sheets and Tourmaline

Emerging applications leverage mineral-specific properties: bio-composite research combines surface-modified talc with chitosan polymers, accelerating wound healing metrics by 35% in clinical trials. Nano-engineered mica sheets demonstrate 99.7% UV reflectance for next-generation photovoltaic encapsulation. Tourmaline's permanent charge separation enables water molecule dissociation efficiency at 85% without catalysts—revolutionizing hydrogen extraction technology. These innovations transform mineral engineering from basic raw materials into advanced technological enablers across industries.

(different types of talcum powder)

FAQS on different types of talcum powder

Q: What are the different types of talcum powder?

A: Different types include cosmetic-grade, industrial-grade, and pharmaceutical-grade talc. Each varies in purity for specific uses, such as body powders or plastics. Particle size determines application safety.

Q: How do different types of talcum powder differ in applications?

A: Cosmetic-grade is for personal care products like baby powder, while industrial-grade supports manufacturing. Pharmaceutical-grade is high-purity for medical ointments. All types must meet regulatory standards.

Q: What are the different types of mica sheets?

A: Common types include muscovite (white or clear) and phlogopite (dark brown). Muscovite offers high heat resistance for electronics, and phlogopite provides flexibility. They differ in chemical composition and cleavage.

Q: Where are different types of mica sheets used in industry?

A: Muscovite sheets are in electrical insulators, while phlogopite is for furnace windows. Both serve decorative purposes in art. Thickness and color variations cater to specific thermal or visual needs.

Q: What are the different types of tourmaline and their features?

A: Types include schorl (black), elbaite (colorful gems), and dravite (brown). Schorl is piezoelectric, elbaite is prized in jewelry, and dravite aids in water filtration. Each has unique mineral properties for varied applications.