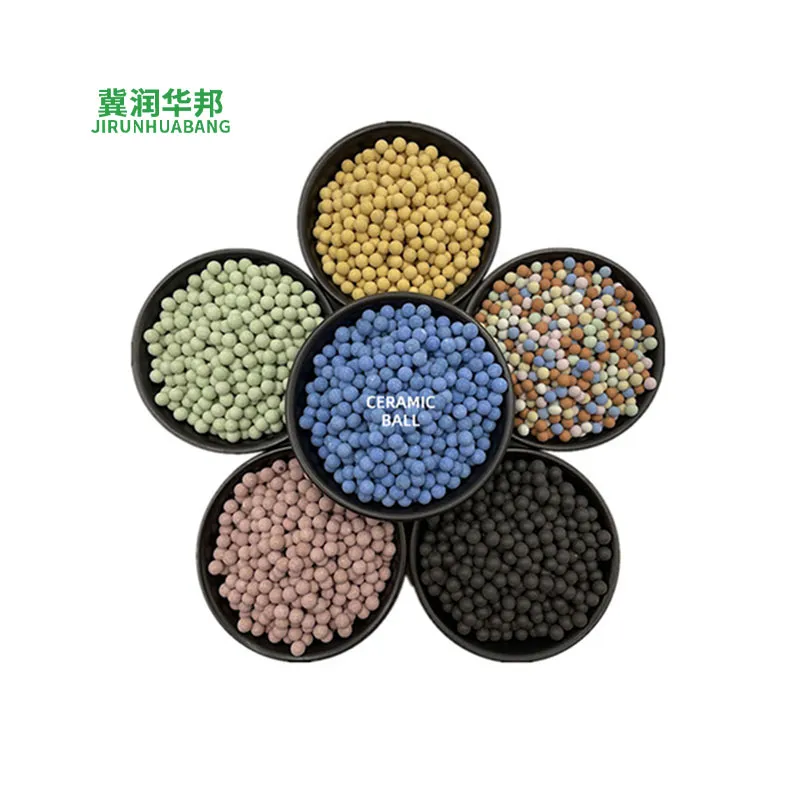

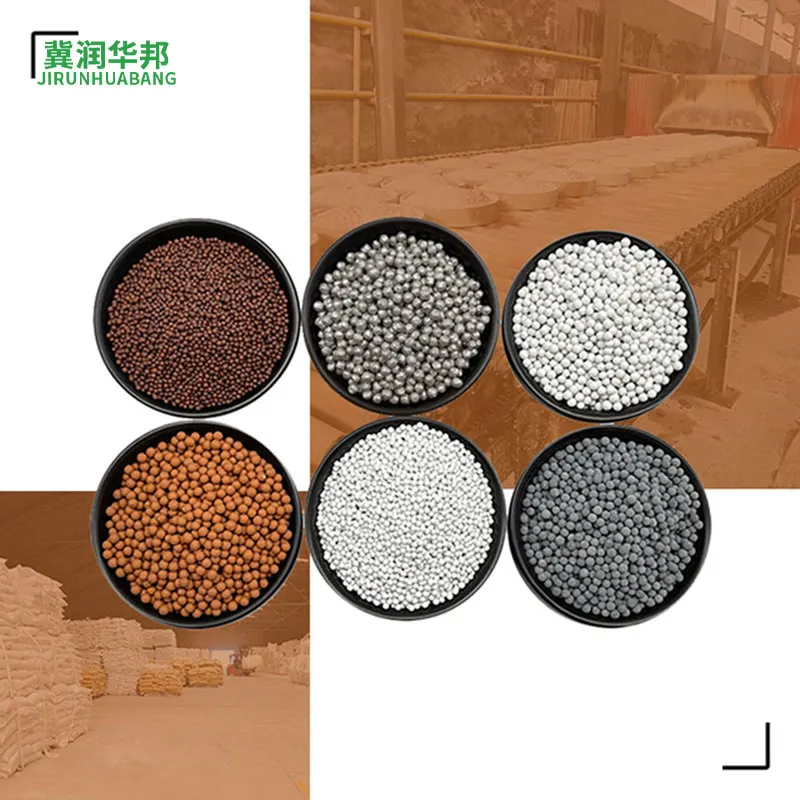

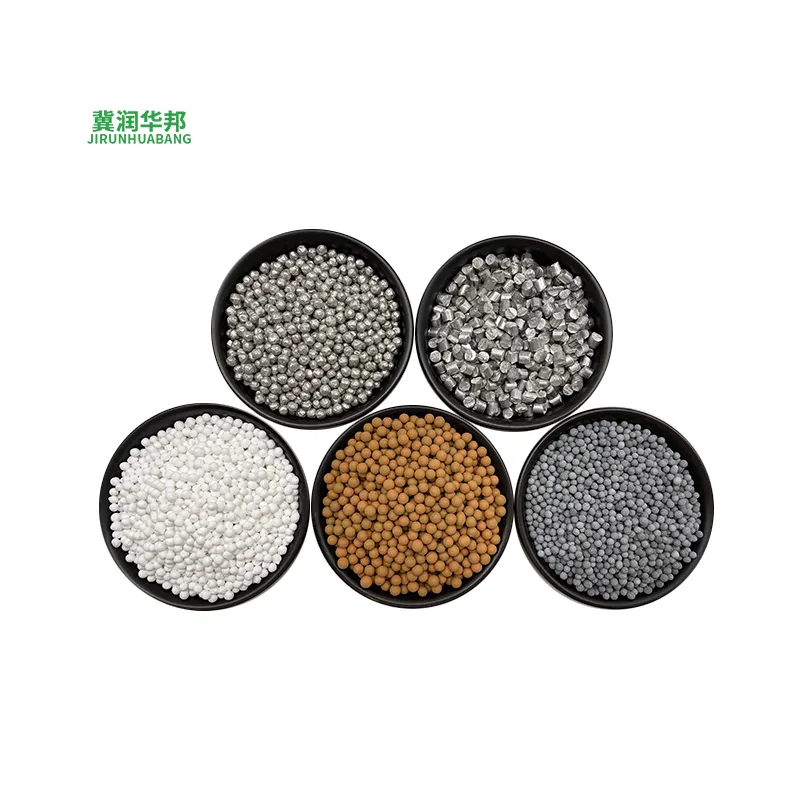

High Alumina Porous Ceramic Packing Ball with High Temp Resistance

Back to list

The High alumina porous ceramic packing ball with high temperature resistance and high hardness is recognized as a forefront solution for challenging applications in petrochemical, metallurgy, wastewater treatment, and environmental industries. This article presents an in-depth discussion on its technical parameters, global trends, manufacturing process, typical applications, and leading manufacturers, offering a comprehensive guide for decision-makers.

1. Industry Trends & Market Insights

As stricter requirements on corrosion resistance, operational efficiency, and sustainability grow across process industries, demand for advanced ceramic packing solutions is rising. Reports show the global advanced ceramics market is valued at $108.3 billion in 2023 (source: GVR), with an expected CAGR above 6.2%. Among these, high alumina-based products, such as High alumina porous ceramic packing ball with high temperature resistance and high hardness, account for a rapidly growing share due to their robustness in harsh environments.

2. Technical Parameters & Performance Specification

High alumina porous ceramic packing ball with high temperature resistance and high hardness stands out due to its exceptional material properties and engineering precision. Below are typical product technical specifications:

| Parameter | Values (Typical) | Standard/Reference |

|---|---|---|

| Al₂O₃ Content (%) | 92–99.5 | ISO 12677:2011 |

| Bulk Density (g/cm³) | 2.3–3.6 | ASTM C373 |

| Porosity (%) | 20–30 | ISO 5017 |

| Crushing Strength (N/particle) | >3500 | ASTM D4179 |

| Max. Operating Temperature (°C) | 1400–1700 | ISO 6744-1 |

| Acid & Alkali Resistance (%) | >99.8 | ISO 6721-1 |

| Wear Loss (mg/1000Revs) | <0.08 | ASTM C704 |

| Water Absorption (%) | <4.5 | ISO 5017 |

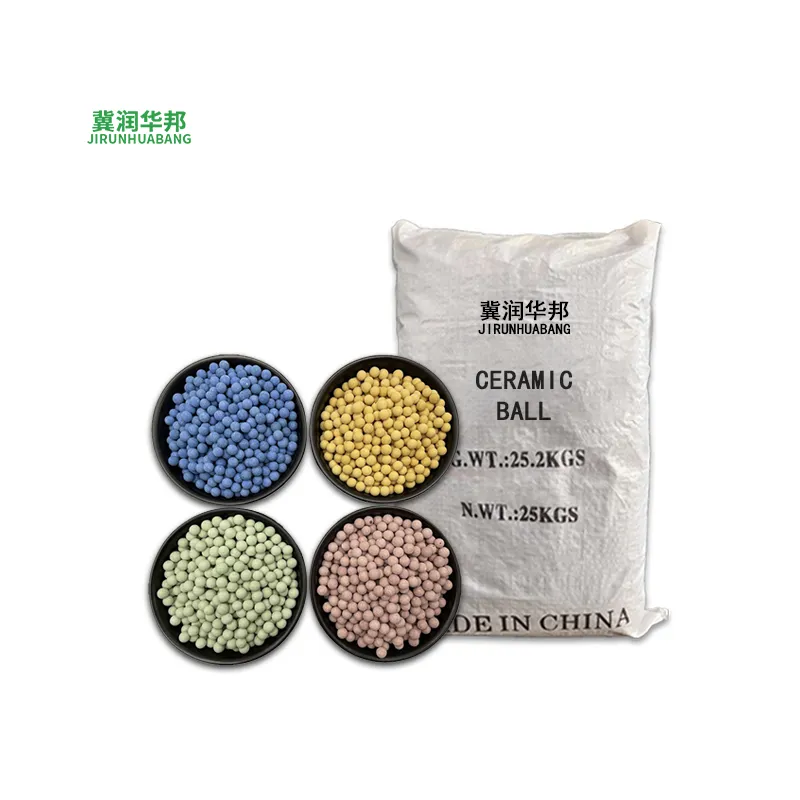

| Customized Sizes (mm) | 3, 6, 10, 13, 20, 25, 50 and up | OEM Available |

For further product details and custom requests, visit the High alumina porous ceramic packing ball with high temperature resistance and high hardness product page.

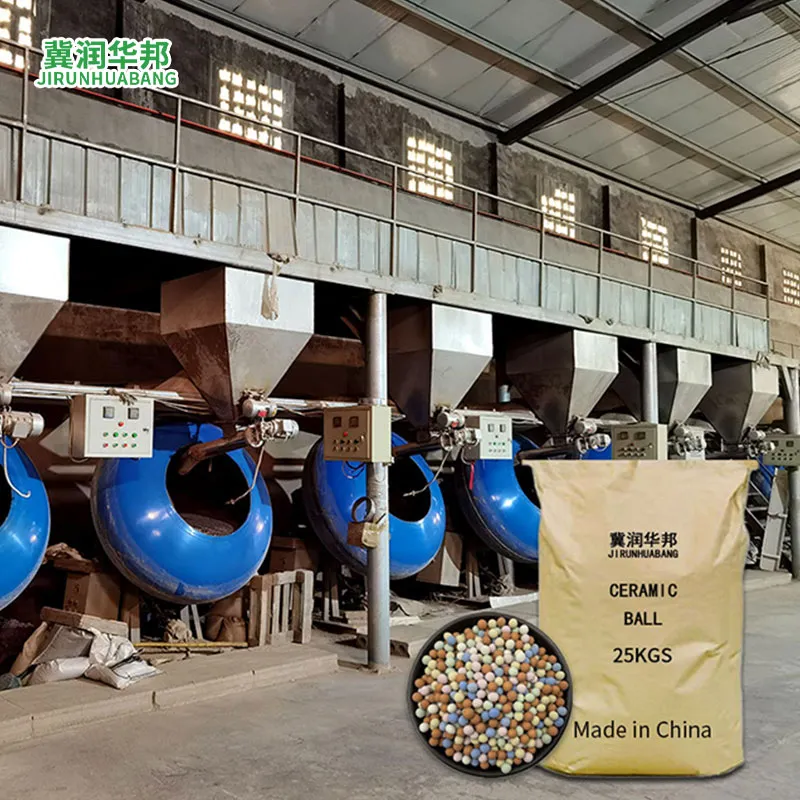

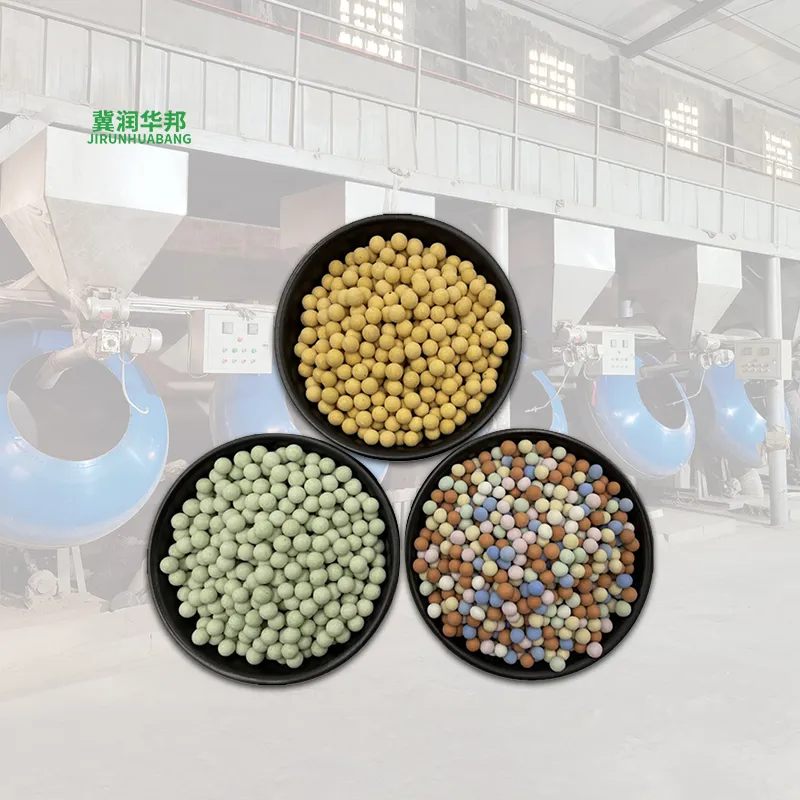

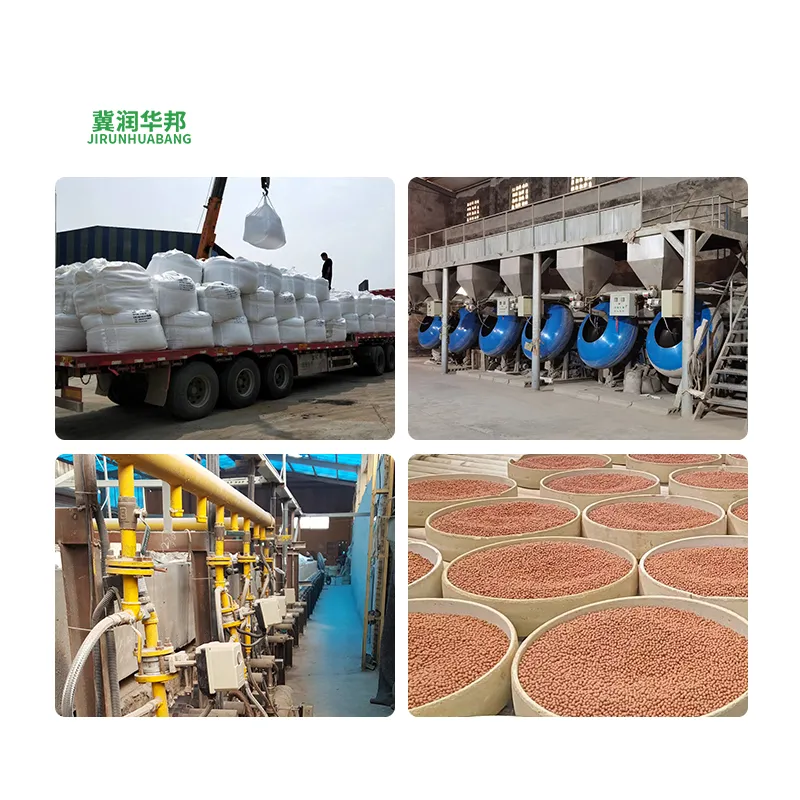

3. Manufacturing Process Flow

High-purity alumina (≥ 99%) and proprietary additives ensure phase stability.

Micro-particle slurry compounded for uniformity in pore structure and strength.

Precision balls formed via extrusion or injection, sized as per ISO 5017.

High-temperature kilns (up to 1730°C) used for densification and porosity control.

Balls ground and polished for dimensional accuracy and surface finish.

ISO/ANSI standard testing (strength, porosity, chemical resistance, etc.) and batch sampling.

Vacuum-sealed or moisture-proof packing, labeled with full traceability.

Note: The combination of advanced sintering with precise CNC finishing guarantees both thermal shock resilience and tight tolerance of particle size, which is critical for high-performance process reactors.

4. Visualizing Data: Performance Trends & Product Comparison

(Graphical data for High alumina porous ceramic packing ball with high temperature resistance and high hardness and competitive alternatives, 2018–2023, sourced from public domain and manufacturer documentation.)

5. Application Scenarios

- Petrochemical Reactors: Used as support and distribution media in reformers, hydrocrackers, and gas absorbers. High resistance to H2S and ammonia.

- Metallurgy Furnaces: As filtration, inert beds, or regenerative layers in blast and electric arc furnaces.

- Waste & Clean Water Treatment: In biological treatment columns, supporting bio-media or as filter back-up in high-flow tanks. Superior durability in aggressive pH environments.

- Environmental Protection: Scrubbing towers, exhaust gas purification and removal of VOCs.

- Catalyst Carriers: Maximizes surface area for active materials, excellent permeability and mechanical support.

Petrochemical Plant, Saudi Arabia

After replacing conventional alumina balls with High alumina porous ceramic packing ball with high temperature resistance and high hardness, the plant observed a 14% increase in catalyst run duration (from 16 to 18.25 months) and over 96% reduction in pressure drop due to improved permeability and mechanical strength.

Advantages in Typical End Use

Advantages in Typical End Use

- Thermal Stability: Survive long-term exposure to temperatures above 1600°C without deformation.

- Chemical Inertness: Resist acid/alkali up to 99.8%, minimizing corrosion and contamination risk.

- Mechanical Hardness: Mohs > 9, suitable for abrasive scenarios where particle fracture is critical.

- Energy Efficiency: Superior voidage and porosity help lower process pressure drop and reduce operational energy.

6. Manufacturer Comparison (2024)

| Manufacturer | Al₂O₃ (%) | Max Temp (°C) | Porosity (%) | Crush Strength (N) | Global Certs | Custom/OEM |

|---|---|---|---|---|---|---|

| Jirun Huabang | 99.2 | 1700 | 28–30 | 3700 | ISO 9001, ANSI, SGS | Yes |

| Saint-Gobain Group | 97.5 | 1550 | 21–25 | 3280 | ISO 9001, ISO 14001 | Partial |

| Pingxiang Chemshun | 99 | 1680 | 25–28 | 3400 | ISO, FDA | Yes |

| Pingxiang FRI | 92 | 1400 | 19–23 | 2750 | ISO | Yes |

7. Customization & Engineering Support

- Size Range: 3mm to 75mm, custom diameters with tolerances ≤±1.5%

- Shape: Sphere/ellipsoid/segment available for packing density optimization

- Material Mix: High-purity alumina, or with zirconia, silicon carbide for extreme scenarios

- Pore Size: Open, closed or bimodal (0.1–30μm options)

- Surface Coating: Hydrophobic, catalytic, or inert surface layering possible.

- Compliance: Certified to ISO 9001, SGS, ANSI/ASTM; traceable batch records offered

- Lead Time: 5–15 business days for standard, 2–5 weeks for OEM/complex specs

Warranty & After-Sales: 18–36 month warranty for qualified use, technical documentation provided, application engineering support from pre-sale to field operation.

8. Real-world Application Cases

Water Treatment Facility, Germany

The client upgraded to High alumina porous ceramic packing ball with high temperature resistance and high hardness to combat high chlorine and acidic discharge. Backwash cycles increased by 44%, while media life extended from 2.2 to 3.6 years.

Steel Plant, Brazil

Implementation in heat recovery towers led to 9% energy efficiency improvement and significant scale reduction per ISO 12677 test regime.

9. Professional FAQ: Key Terms and Usage

A: The primary material is high purity α-phase alumina (Al₂O₃, >99%), optionally modified with stabilizers for extreme thermal endurance.

A: Porosity is quantified via ISO 5017 using mercury intrusion or gas displacement; it determines packing efficiency, permeability, and catalyst hold-up.

A: ASTM D4179 standard applies, with values exceeding 3500N indicating high mechanical resilience for reactor support.

A: Tolerances typically kept to ≤±1.5% in diameter with roundness deviation below 1.2%, per ISO/customer drawings.

A: Yes, both FDA and DEQ (potable water) compliancy are possible, subject to request.

A: Absolutely, their maximum service temperature reaches up to 1700°C, with alumina phase stability ensured by precise sintering and phase testing.

A: Each batch is subject to SGS/ISO 9001 certifications, with full traceability logs, property certificates, and sample retention for 5+ years.

10. FAQ & Customer Support

- What is the typical delivery time? — For in-stock sizes: 5–15 days, OEM orders: 2–5 weeks, sea/air as per client request.

- What warranty is provided? — 18–36 months, covering manufacturing defects and on-site technical support.

- Is technical assistance offered for on-site installation or troubleshooting? — Yes, remote and on-site assistance available globally.

- How to order custom size or performance grade? — Send drawings/specs directly or request engineering consultation via the product page.

- Which industries are best suited? — Petrochemical, refinery, water processing, metallurgy, air separation, catalytic reactors, chemical synthesis, and high-temp non-ferrous furnaces.

- What documentation is available? — Mill test reports, inspection logs, ISO/SGS certificates, and usage recommendations provided for all shipments.

- Compliant to ISO 9001:2015, ANSI/ASTM, FDA (on request), SGS verified.

- Key clients include: BASF, Sinopec Group, Bayer, ArcelorMittal, and Veolia (reference on request).

- Featured in: The American Ceramic Society and ScienceDirect: Porous Ceramics

Contact our technical team now, or request detailed case studies and test data for your application!

11. References & Further Reading

- The American Ceramic Society. "Porous Ceramic Materials: Applications and Market Trends." Ceramic Tech Today. Read more

- ScienceDirect. "Porous Ceramic – Overview and Applications." Read more

- Grand View Research. "Advanced Ceramics Market Analysis Report." Read more

- Ceramic Industry Forum, 2024. "Recent Advances in Alumina Ceramic Packing Balls." [Forum] Read more

- ISO Standards for Refractory Materials. "ISO 12677:2011, ISO 5017:2013, ASTM D4179, ASTM C704."