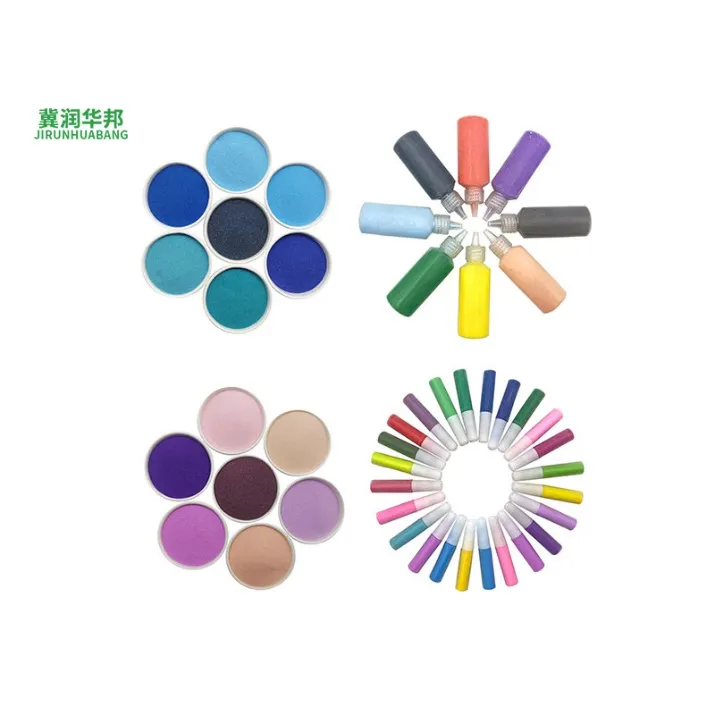

Runhuabang Imitation stone color sand European building exterior wall natural color sand real stone paint color sand color models are complete

Back to list

Feb . 20, 2025 14:04

Polypropylene, commonly abbreviated as PP, is a versatile thermoplastic polymer known for its wide range of applications, making it a staple material across numerous industries. Its unique properties, such as high resistance to chemical solvents, acids, and bases, set it apart from other materials and lend to its utilization in diverse environments.

Polypropylene also finds critical applications in the automotive industry. The demand for lightweight yet sturdy materials is ever-increasing as automakers strive to enhance fuel efficiency without compromising on safety or performance. PP plays a pivotal role here, evident in car battery casings, bumpers, and interior components. The use of polypropylene in manufacturing these parts contributes to a lighter vehicle, allowing for reductions in fuel consumption and emissions. Meanwhile, its impact resistance increases the safety and longevity of automotive components, presenting not just efficiency but reliability. Another significant domain where polypropylene proves indispensable is in construction. Utilized in manufacturing piping systems, its corrosion resistance and durability make it a superior choice for water and heating systems. PP pipes minimize the likelihood of leaks and failures, ensuring efficient and safe transportation of liquids through infrastructural networks. In addition, its adaptability allows for the repair and maintenance of plumbing systems with ease, often without needing complete system overhauls. The environmental impact of polypropylene has also seen recent advancements. As sustainability becomes an increasing priority, PP's recyclability has made this material even more attractive. Waste polypropylene can be reprocessed into a new product, reducing the demand for raw plastics and minimizing landfill contributions. Companies dedicated to eco-friendly initiatives harness the recyclability of PP to drive circular economies, encouraging the reuse of materials and energy conservation. In conclusion, polypropylene's adoption across industries stems from its combination of physical and chemical properties. Its contribution to improving product durability, safety, cost-efficiency, and sustainability underpins its ongoing relevance and expansion in modern applications. As technology and manufacturing processes evolve, the opportunities to utilize polypropylene in innovative ways will only increase, solidifying its position as a material of choice across varied sectors.

Polypropylene also finds critical applications in the automotive industry. The demand for lightweight yet sturdy materials is ever-increasing as automakers strive to enhance fuel efficiency without compromising on safety or performance. PP plays a pivotal role here, evident in car battery casings, bumpers, and interior components. The use of polypropylene in manufacturing these parts contributes to a lighter vehicle, allowing for reductions in fuel consumption and emissions. Meanwhile, its impact resistance increases the safety and longevity of automotive components, presenting not just efficiency but reliability. Another significant domain where polypropylene proves indispensable is in construction. Utilized in manufacturing piping systems, its corrosion resistance and durability make it a superior choice for water and heating systems. PP pipes minimize the likelihood of leaks and failures, ensuring efficient and safe transportation of liquids through infrastructural networks. In addition, its adaptability allows for the repair and maintenance of plumbing systems with ease, often without needing complete system overhauls. The environmental impact of polypropylene has also seen recent advancements. As sustainability becomes an increasing priority, PP's recyclability has made this material even more attractive. Waste polypropylene can be reprocessed into a new product, reducing the demand for raw plastics and minimizing landfill contributions. Companies dedicated to eco-friendly initiatives harness the recyclability of PP to drive circular economies, encouraging the reuse of materials and energy conservation. In conclusion, polypropylene's adoption across industries stems from its combination of physical and chemical properties. Its contribution to improving product durability, safety, cost-efficiency, and sustainability underpins its ongoing relevance and expansion in modern applications. As technology and manufacturing processes evolve, the opportunities to utilize polypropylene in innovative ways will only increase, solidifying its position as a material of choice across varied sectors.

Share