calcium carbonate powder price

Back to list

2 月 . 04, 2025 00:39

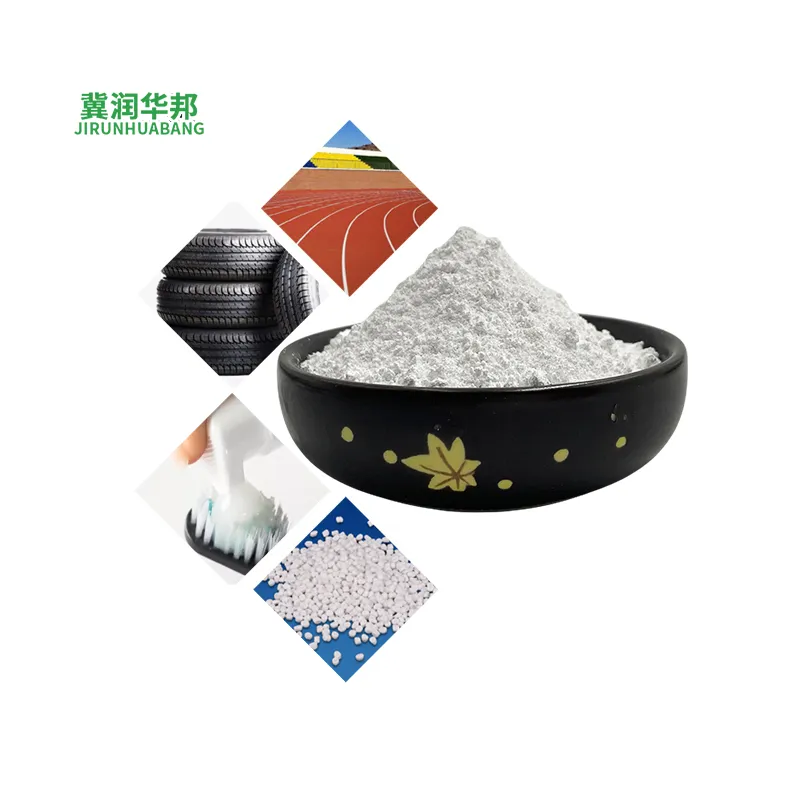

Calcium carbonate powder is a versatile industrial compound extensively used across various sectors such as construction, agriculture, and manufacturing. Understanding its market pricing dynamics is essential for businesses aiming to leverage its benefits both economically and operationally.

Buying in bulk can also influence the cost-effectiveness for companies. Many suppliers offer substantial discounts on large orders, impacting the unit price beneficially for large-scale consumers. This aspect is particularly relevant for manufacturers involved in high-volume production where calcium carbonate serves as a key ingredient. In terms of expertise, having an in-depth understanding of the calcium carbonate supply chain can afford businesses considerable leverage over market prices. Engaging with reputable suppliers who offer transparency in pricing and quality can create a trustworthy relationship, ensuring consistent product availability without sudden price spikes. Furthermore, fluctuations in global economic conditions, such as inflation and exchange rates, also have a significant impact on the price of calcium carbonate powder. For instance, global economic recovery can boost industrial activities, thereby increasing demand and influencing cost structures. In conclusion, while multiple dynamic factors influence the pricing of calcium carbonate powder, staying informed and strategically navigating these elements can help businesses optimize their procurement strategies. Consistently monitoring market trends, maintaining a close relationship with reliable suppliers, and investing in efficient technologies can ensure a stable supply chain, making calcium carbonate powder a sustainably cost-effective resource across industries. Understanding these intricacies not only demonstrates expertise but also establishes a firm's authority and trustworthiness in its domain.

Buying in bulk can also influence the cost-effectiveness for companies. Many suppliers offer substantial discounts on large orders, impacting the unit price beneficially for large-scale consumers. This aspect is particularly relevant for manufacturers involved in high-volume production where calcium carbonate serves as a key ingredient. In terms of expertise, having an in-depth understanding of the calcium carbonate supply chain can afford businesses considerable leverage over market prices. Engaging with reputable suppliers who offer transparency in pricing and quality can create a trustworthy relationship, ensuring consistent product availability without sudden price spikes. Furthermore, fluctuations in global economic conditions, such as inflation and exchange rates, also have a significant impact on the price of calcium carbonate powder. For instance, global economic recovery can boost industrial activities, thereby increasing demand and influencing cost structures. In conclusion, while multiple dynamic factors influence the pricing of calcium carbonate powder, staying informed and strategically navigating these elements can help businesses optimize their procurement strategies. Consistently monitoring market trends, maintaining a close relationship with reliable suppliers, and investing in efficient technologies can ensure a stable supply chain, making calcium carbonate powder a sustainably cost-effective resource across industries. Understanding these intricacies not only demonstrates expertise but also establishes a firm's authority and trustworthiness in its domain.

Share

Next: