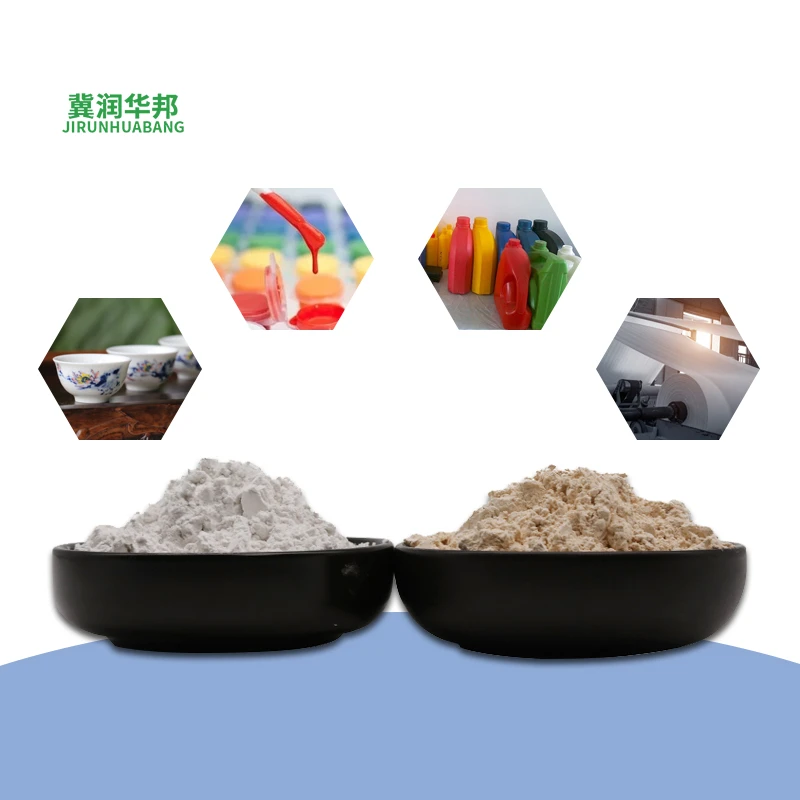

Runhuabang Wholesales All Size Paint Textile Tourmaline Powder Superfine Grade Tourmaline White Black Tourmaline Powder Particle

Back to list

Februari . 19, 2025 09:20

The use of talc powder has garnered attention across various industries due to its versatile applications. Originally recognized for its use in personal care and cosmetic products, talc powder offers a myriad of benefits that extend into several product categories. To understand the unique attributes of talc powder and how it can enhance product performance, it is essential to delve into its properties and applications.

In ceramics, talc is used to improve the vitrification process. Its incorporation into ceramic products aids in lowering firing temperatures, improving thermal shock resistance, and enhancing the final product's surface quality. This application is critical in the production of tiles, sanitary ware, and tableware, where aesthetic and structural integrity is paramount. Furthermore, the paper industry benefits from talc powder's opacity and brightness properties, which are essential for high-quality paper production. Talc's lamellar structure enhances smoothness and printability, ensuring premium paper products that meet professional standards. The trusted use of talc in this industry exemplifies its indispensable role in delivering superior quality products. Sustainability is an increasingly important factor across all industries, and talc is a naturally occurring mineral that requires minimal processing, aligning it with eco-friendly standards. Suppliers emphasize responsible mining practices, ensuring a sustainable supply chain that supports the growing demand while maintaining environmental integrity. This trustworthiness in sourcing and application makes talc a preferred choice for companies pursuing green initiatives. In conclusion, the diverse applications of talc powder demonstrate its irreplaceable role across multiple industries, offering not only quality and efficiency but also sustainability. Its unique properties and broad applicability underscore its importance, supported by a foundation of authoritative research and expert validation. As industries evolve, the versatility and reliability of talc powder ensure its continued significance in product innovation and quality assurance.

In ceramics, talc is used to improve the vitrification process. Its incorporation into ceramic products aids in lowering firing temperatures, improving thermal shock resistance, and enhancing the final product's surface quality. This application is critical in the production of tiles, sanitary ware, and tableware, where aesthetic and structural integrity is paramount. Furthermore, the paper industry benefits from talc powder's opacity and brightness properties, which are essential for high-quality paper production. Talc's lamellar structure enhances smoothness and printability, ensuring premium paper products that meet professional standards. The trusted use of talc in this industry exemplifies its indispensable role in delivering superior quality products. Sustainability is an increasingly important factor across all industries, and talc is a naturally occurring mineral that requires minimal processing, aligning it with eco-friendly standards. Suppliers emphasize responsible mining practices, ensuring a sustainable supply chain that supports the growing demand while maintaining environmental integrity. This trustworthiness in sourcing and application makes talc a preferred choice for companies pursuing green initiatives. In conclusion, the diverse applications of talc powder demonstrate its irreplaceable role across multiple industries, offering not only quality and efficiency but also sustainability. Its unique properties and broad applicability underscore its importance, supported by a foundation of authoritative research and expert validation. As industries evolve, the versatility and reliability of talc powder ensure its continued significance in product innovation and quality assurance.

Share