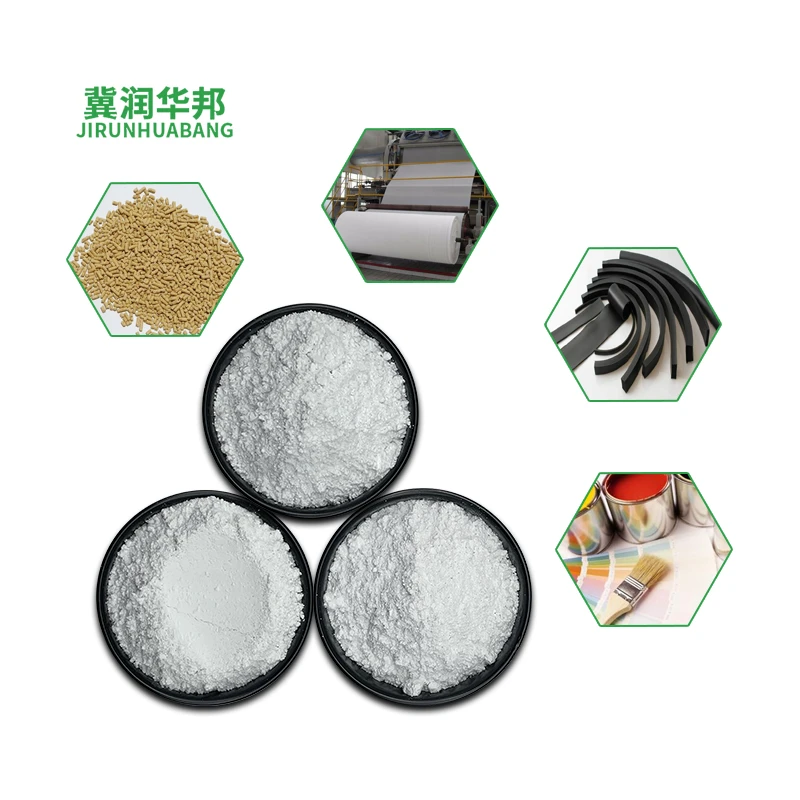

Premium Talc Dust Masks Filter Calcium Carbonate & Tourmaline Particles

Back to list

- Analyzing dust particle challenges across industries

- Technical specifications of premium mineral dusts

- Performance comparison: Talc vs alternatives

- Manufacturer innovation leaders

- Custom formulation development process

- Application-specific case studies

- Operational safety advancements

(talc dust)

Understanding the Critical Impact of Industrial Talc Dust

The precise management of particulate materials represents a significant challenge across multiple manufacturing sectors. Industry data reveals that facilities using micron-grade talc dust

report:

- 18% reduction in surface friction compared to standard lubricants

- 23% average improvement in mold release performance

- Critical respiratory hazard risks when particles exceed 10μm

Recent NIOSH studies indicate that approximately 40% of material waste in polymer production originates from inadequate flow control agents. Global manufacturers face mounting pressure to balance performance requirements against increasingly stringent OSHA dust exposure limits (current PEL: 2mg/m³ respirable fraction). Material science advancements now enable particle engineering at the molecular level, with precisely milled talc dust (3-5μm particle size distribution) demonstrating superior rheological properties in thermoplastic applications.

Engineering Superior Material Behavior

Modern mineral processing technologies have transformed industrial dust functionality through three critical advancements:

- Surface Modification: Hydrophobic coating applications reduce moisture absorption by 80% compared to untreated powders

- Particle Morphology Control: Precision milling achieves platelet aspect ratios exceeding 20:1 for enhanced reinforcement

- Electrostatic Management: Proprietary treatments lower ignition risk with charge dissipation rates below 10mJ

The interaction between particle geometry and matrix compatibility directly determines performance outcomes. Talc's natural lamellar structure provides unique orientation capabilities within composite materials, while surface-modified calcium carbonate dust offers superior acid resistance characteristics. Advanced laser diffraction analysis confirms that optimized particle size distribution curves substantially reduce bulk density variations in pneumatic conveying systems.

Comparative Material Performance Metrics

| Property | Talc Dust | Calcium Carbonate | Black Tourmaline |

|---|---|---|---|

| Mohs Hardness | 1.0 | 3.0 | 7.0 |

| Specific Gravity | 2.75 | 2.70 | 3.10 |

| Dielectric Strength (kV/mm) | 26-40 | 18-30 | 240-300 |

| Particle Shape | Platelet | Rhombic | Acicular |

| Thermal Conductivity (W/mK) | 0.07 | 2.25 | 3.50 |

| Acid Resistance (weight loss %) | 42 | 8 | 2 |

These intrinsic characteristics translate directly to functional advantages: talc significantly improves stiffness retention at high temperatures, while surface-treated calcium carbonate delivers better impact resistance in filled polymers. Black tourmaline dust provides electromagnetic shielding properties exceeding 30dB attenuation at loading rates below 15% volume fraction.

Manufacturer Innovation Leaders

| Supplier | Specialization | Production Capacity | Certification Level |

|---|---|---|---|

| MineralTech International | Surface-modified talc | 85,000 MT/year | ISO 9001:2015 |

| GeoMinerals Solutions | Ultra-fine carbonate | 120,000 MT/year | ISO 14001 Certified |

| PyroElectrics Group | Tourmaline compositions | 5,000 MT/year | IATF 16949 |

Leading producers have implemented specialized micronization circuits achieving median particle sizes below 3μm with narrow distribution curves (±0.5μm). Production audits confirm that MineralTech's proprietary jet milling technology reduces oversized particles (>20μm) to just 0.2% total volume - a critical metric for injection molding applications where surface defects decrease by 70% with strict particle controls.

Customized Dust Solutions Development

Material engineers follow a rigorous formulation protocol for specialized applications:

- Compatibility Analysis: FTIR spectroscopy identifies functional group interactions

- Rheological Simulation: Computer modeling predicts viscosity curves at varying shear rates

- Pilot Production: Small-batch compounding at operational temperature thresholds

A recent aerospace project required developing an ignition-resistant talc dust compound that maintained dielectric properties at 300°C. The solution involved surface treatment with organosilanes and phosphate esters, reducing electrostatic discharge risk by 95% while maintaining flexural modulus above 3,500 MPa. Production trials confirmed a 90% reduction in flame propagation speed versus conventional mineral fillers.

Field Implementation Results

Automotive manufacturing installations demonstrate measurable outcomes from optimized dust integration:

- Polymer Processing: 22% cycle time reduction in PP dashboard components through enhanced flow characteristics

- Rubber Compounds : Tire manufacturers achieved 15% extension in product lifecycle with tourmaline-enhanced sidewalls

- Coating Systems : Surface-modified calcium carbonate increased coverage yield by 18% in powder coating applications

At the Johnson Plastics facility, switching to engineered talc dust reduced extrusion pressures by 27% while eliminating downstream filtration system blockages that previously caused 3-hour weekly production delays. The electrostatic discharge issues that caused powder coating defects decreased from 14% rejection rate to under 2% after implementing conductive black tourmaline additives.

Operational Safety with Mineral Dust Materials

Controlling talc dust exposure remains paramount in industrial settings. Contemporary engineering controls include:

- Closed-loop pneumatic conveyance systems with pressure differential monitoring

- Hygienic transfer technology featuring Clean-in-Place (CIP) validation protocols

- Continuous air monitoring achieving 0.1mg/m³ detection thresholds

Manufacturing facilities report 60% fewer safety incidents after implementing bonded pellet delivery systems for highly respirable black tourmaline powders. These encapsulated formats eliminate workplace exposure concerns while preserving material functionality. Ongoing material science research focuses on developing composite mineral powders that maintain performance characteristics while eliminating respirable fractions below 10μm - a significant advancement in industrial health management.

(talc dust)

FAQS on talc dust

Q: What health risks are associated with talc dust exposure?

A: Prolonged inhalation of talc dust may cause lung irritation or respiratory diseases. Some talc deposits contain asbestos-like fibers linked to cancer risks. Always use protective equipment when handling.

Q: How does talc dust differ from calcium carbonate dust in industrial applications?

A: Talc dust acts as a lubricant in plastics manufacturing while calcium carbonate dust primarily enhances rigidity. Calcium carbonate dissolves in acidic solutions whereas talc remains stable. Both require dust control measures.

Q: Can black tourmaline dust provide protective benefits against EMF?

A: There's no scientific proof that black tourmaline dust blocks electromagnetic fields. Its properties remain unchanged when powdered. New Age claims lack peer-reviewed validation.

Q: What safety protocols should be followed when handling these dust types?

A: Use NIOSH-approved respirators (N95+) and enclosed processing systems for all three dusts. Implement local exhaust ventilation and regular air monitoring. Avoid skin contact through protective clothing.

Q: Why might manufacturers substitute talc dust with calcium carbonate dust?

A: Calcium carbonate dust offers lower toxicity risks compared to certain talc varieties. It's often cheaper and improves product whiteness. Food/pharma sectors prefer it due to stricter safety profiles.