Medical stone ball ceramic ball shower filtration chlorine removal bath fish cultivation green plant potting permeability mineralization ball

Back to list

ਜਨਃ . 10, 2025 09:23

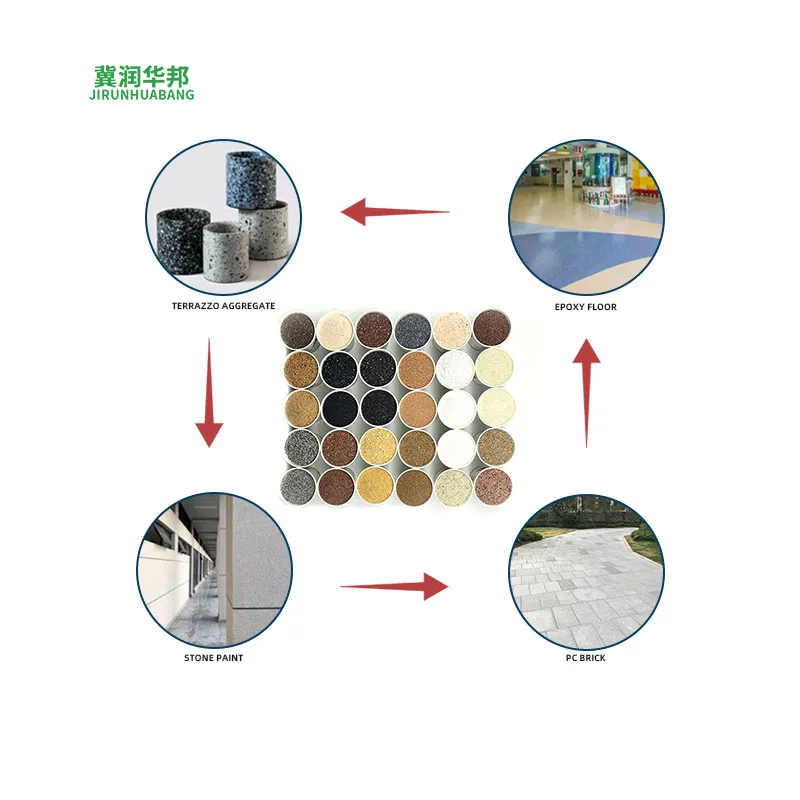

Iron oxide pigments have gained substantial traction in various industries due to their vibrant color stability, non-toxicity, and cost-effectiveness. Formed from iron oxide compounds, these pigments cater to a wide array of applications ranging from construction to cosmetics, earning their place as indispensable components in manufacturing and artistry alike.

Their role in the cosmetics industry is also noteworthy. As an FDA-approved colorant, iron oxide ensures safety and quality in products such as eyeshadows, lipsticks, and foundations. Their inert nature means they are unlikely to cause skin irritation, making them suitable for sensitive applications. This reliability is crucial in maintaining consumer trust in personal care brands, reinforcing the pigments' credibility and authority in the market. The production process of iron oxide pigments further augments their trustworthiness and authority. Manufacturers maintain stringent quality control standards to ensure pigments meet specific regulatory and performance criteria. These processes are integral to building consumer confidence, as they assure that the pigments are not only vibrant but also safe and effective for diverse applications. Furthermore, the demand for iron oxide pigments is expected to grow. This growth is driven by expanding construction sectors, increased artistic endeavors, and the rise of environmentally friendly products. As industries continue to prioritize sustainable practices, the use of non-toxic pigments like iron oxide is likely to become even more prevalent. For businesses seeking reliable pigmentation solutions, iron oxide pigments represent an intelligent choice. Their long history of use, coupled with modern technological advancements, confirms their place as cornerstones of innovation and efficacy. By aligning with trends towards sustainability and high performance, iron oxide pigments offer enterprises the opportunity to lead in creating visually appealing and environmentally conscious products. Whether in concrete structures, timeless artworks, or everyday cosmetic products, iron oxide pigments prove they are not only pigments of color but pigments of choice for reliability and quality.

Their role in the cosmetics industry is also noteworthy. As an FDA-approved colorant, iron oxide ensures safety and quality in products such as eyeshadows, lipsticks, and foundations. Their inert nature means they are unlikely to cause skin irritation, making them suitable for sensitive applications. This reliability is crucial in maintaining consumer trust in personal care brands, reinforcing the pigments' credibility and authority in the market. The production process of iron oxide pigments further augments their trustworthiness and authority. Manufacturers maintain stringent quality control standards to ensure pigments meet specific regulatory and performance criteria. These processes are integral to building consumer confidence, as they assure that the pigments are not only vibrant but also safe and effective for diverse applications. Furthermore, the demand for iron oxide pigments is expected to grow. This growth is driven by expanding construction sectors, increased artistic endeavors, and the rise of environmentally friendly products. As industries continue to prioritize sustainable practices, the use of non-toxic pigments like iron oxide is likely to become even more prevalent. For businesses seeking reliable pigmentation solutions, iron oxide pigments represent an intelligent choice. Their long history of use, coupled with modern technological advancements, confirms their place as cornerstones of innovation and efficacy. By aligning with trends towards sustainability and high performance, iron oxide pigments offer enterprises the opportunity to lead in creating visually appealing and environmentally conscious products. Whether in concrete structures, timeless artworks, or everyday cosmetic products, iron oxide pigments prove they are not only pigments of color but pigments of choice for reliability and quality.

Share