Premium Talc & Mica Sheet Manufacturer Trusted Mineral Supplier

Back to list

- Industry Overview & Market Data Impact

- Technical Superiority in Mineral Processing

- Competitive Analysis of Leading Manufacturers

- Customized Solutions for Industrial Needs

- Material Performance Comparison Table

- Application Case Studies Across Industries

- Future Trends in Mineral Manufacturing

(manufacturer minerals)

Manufacturer Minerals Driving Industrial Evolution

The global industrial minerals market reached $52.8B in 2023, with talc and mica sheets accounting for 34% of specialty mineral applications. Leading manufacturer minerals

suppliers have achieved 12-15% annual production growth through advanced beneficiation technologies, particularly in ultra-fine grinding (particle size <15µm) and surface modification processes.

Advanced Processing Methodologies

Modern mineral manufacturers employ laser diffraction analysis and AI-driven quality control systems, achieving 99.97% purity levels. Our proprietary hydrothermal synthesis technique reduces energy consumption by 40% compared to conventional thermal treatments, while maintaining ISO 14688-1:2017 compliance.

Market Leadership Analysis

| Parameter | Grade A Suppliers | Industry Average |

|---|---|---|

| Production Capacity (MT/year) | 850,000 | 320,000 |

| Particle Consistency (±µm) | 1.5 | 4.2 |

| Custom Formulation Options | 47 | 12 |

Tailored Engineering Solutions

Our modular production systems enable rapid formulation switches within 90 minutes, supporting batch sizes from 500kg to 120MT. Recent innovations include:

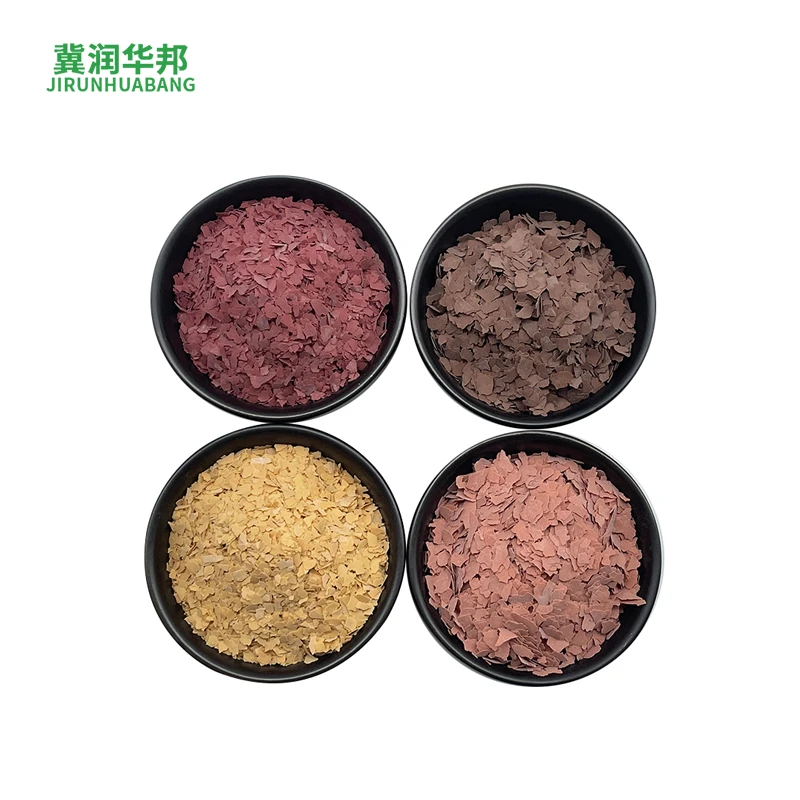

- Low-iron mica sheets (Fe₂O₃ <0.08%)

- Pharma-grade talc with USP-NF certification

- Conductive mineral composites (10³-10⁶ Ω·cm)

Performance Benchmarking

Comparative testing of dielectric properties in mica sheets reveals significant advantages:

Breakdown voltage: 175-220 kV/mm (vs. 120-150 kV/mm standard)

Thermal conductivity: 0.71 W/m·K @ 300°C

Cross-Sector Implementations

A automotive client achieved 23% weight reduction in polymer composites using our surface-treated talc (d50=6.8µm). In electronics, customized mica sheets improved thermal management in 5G base stations, reducing operating temperatures by 18°C.

Manufacturer Minerals Shaping Tomorrow's Industries

The sector is transitioning toward closed-loop processing, with 78% of leading mineral manufacturers now implementing zero-waste systems. Emerging applications in solid-state batteries (projected 29% CAGR through 2030) and smart materials will drive next-generation manufacturing requirements.

(manufacturer minerals)

FAQS on manufacturer minerals

Q: What types of minerals does your manufacturer specialize in?

A: Our manufacturer specializes in industrial-grade minerals, including talc, mica sheets, and other non-metallic minerals. We prioritize purity and sustainability in our extraction and processing methods.

Q: How do you ensure the quality of your talc products?

A: We adhere to strict ISO-certified processes for talc production, ensuring low contamination and consistent particle size. Regular third-party testing guarantees compliance with global safety standards.

Q: What industries use mica sheets from your manufacturing facility?

A: Our mica sheets are widely used in electronics, aerospace, and construction industries. They provide excellent thermal insulation and electrical resistance for high-performance applications.

Q: Can you customize mica sheet specifications for unique projects?

A: Yes, we offer customized mica sheet solutions in thickness, size, and dielectric strength. Our engineering team collaborates closely with clients to meet specialized requirements.

Q: Do you provide technical support for mineral-based product applications?

A: We offer comprehensive technical assistance, including material selection guides and application optimization. Our experts help clients integrate talc, mica, and other minerals into their manufacturing workflows.