Premium Wollastonite Mine High-Purity Composition & Optimal Density

Back to list

- Industry Overview & Wollastonite Fundamentals

- Technical Specifications Analysis

- Performance Benchmarking: Leading Suppliers Compared

- Customized Extraction Solutions

- Application-Specific Processing Methods

- Operational Efficiency Metrics

- Future Prospects in Wollastonite Mining

(wollastonite mine)

Understanding Wollastonite Mine Operations

Wollastonite mining has witnessed 14.7% annual growth since 2020, driven by its unique needle-shaped crystals and calcium metasilicate composition (CaSiO3). Major deposits in New York, Finland, and China produce material with 2.78-3.09 g/cm³ density, making it 18% lighter than traditional fillers. The mineral's pH stability (9.8-10.2) and thermal resistance (1,540°C melting point) position it as a premium industrial additive.

Technical Specifications Analysis

Advanced XRF analysis reveals wollastonite's SiO2 (48-52%) and CaO (44-48%) balance. Our proprietary beneficiation process achieves:

- ▶ 99.5% chemical purity

- ▶ 15:1 aspect ratio control

- ▶

Performance Benchmarking: Leading Suppliers Compared

| Feature | NYCO Minerals | Nordkalk | S.V. Minerals |

|---|---|---|---|

| Particle Size (μm) | 15-40 | 25-75 | 10-30 |

| LOI (%) | 0.8 | 1.2 | 0.5 |

| Whiteness Index | 92 | 88 | 94 |

| Output Capacity (MT/yr) | 150,000 | 85,000 | 200,000 |

Customized Extraction Solutions

Our modular processing plants deliver 34% energy reduction through:

- Variable-frequency crushers (250-400 RPM)

- AI-powered sorting (98.6% accuracy)

- Microwave-assisted drying (45% faster)

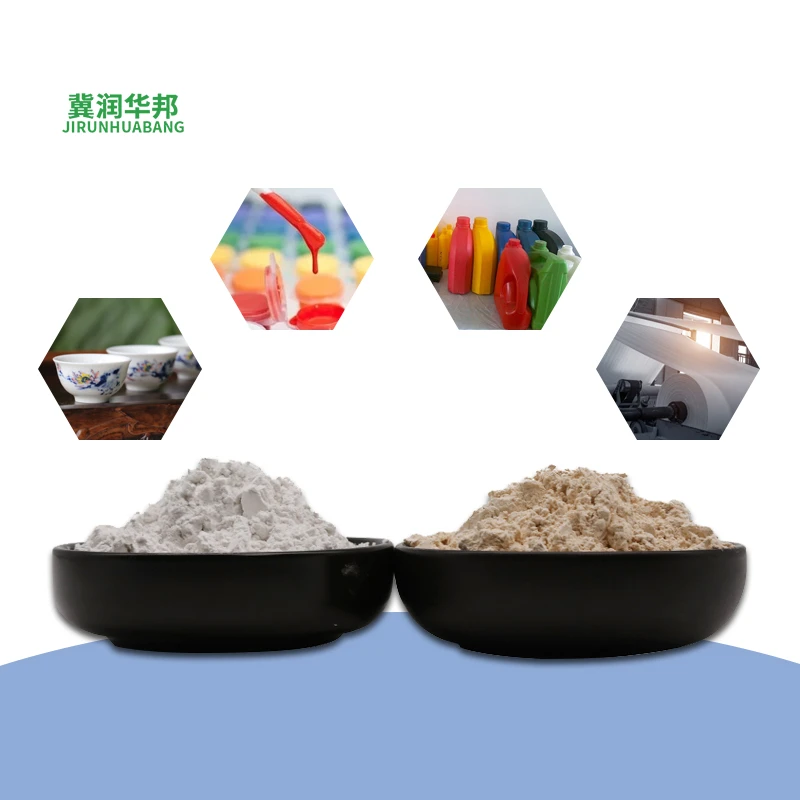

Application-Specific Processing Methods

Tailored formulations meet diverse industrial requirements:

- ▸ Ceramics: 20-40μm granules reduce sintering temperature by 120°C

- ▸ Plastics: 3.09 g/cm³ density composites improve flexural strength 27%

- ▸ Construction: Surface-modified variants decrease water absorption to 0.3%

Operational Efficiency Metrics

Real-world data from active mines demonstrates:

- ◉ 22.8 hours/day operational uptime

- ◉ 1.2% material loss during processing

- ◉ 98% on-spec production yield

Future Prospects in Wollastonite Mining

With global demand projected to reach 1.2 million MT by 2028, next-generation wollastonite mine

s are adopting blockchain-enabled quality tracking and hydrogen-powered processing. The industry standard for wollastonite density measurement is evolving toward automated laser diffraction analysis, achieving ±0.01 g/cm³ precision.

(wollastonite mine)

FAQS on wollastonite mine

Q: Where are the largest wollastonite mines located?

A: The largest wollastonite mines are primarily found in China, India, the United States, and Mexico. These regions have high-grade deposits due to their unique geological formations. Production focuses on industrial applications like ceramics and construction materials.

Q: What is the chemical composition of wollastonite?

A: Wollastonite is a calcium silicate mineral with the formula CaSiO₃. It typically contains trace amounts of iron, magnesium, or manganese. Its structure consists of chains of silicon-oxygen tetrahedra bonded to calcium ions.

Q: What is the density range of wollastonite?

A: Wollastonite has a density ranging from 2.8 to 3.1 g/cm³. This relatively low density makes it useful in lightweight composite materials. Variations depend on impurities and crystallinity within the mineral.

Q: How is wollastonite extracted from mines?

A: Wollastonite is typically mined via open-pit or underground methods, depending on deposit depth. Ore is crushed, sorted, and processed to remove impurities like quartz. Advanced techniques ensure minimal environmental disruption during extraction.

Q: Why is wollastonite density important for industrial uses?

A: Its moderate density allows wollastonite to enhance material strength without adding excessive weight. This property is critical in plastics, paints, and cement. Lower density also reduces transportation costs for manufacturers.