Understanding the Meaning of Cenospheres

Back to list

The term cenospheres refers to lightweight, hollow, microspherical particles made primarily of silica, alumina, and other mineral compounds. They are byproducts of coal combustion, formed during the production of fly ash in thermal power plants. These spherical particles are known for their unique combination of low density and high strength, making them ideal for a wide range of industrial applications. The cenospheres' unique properties, such as their low weight and high resistance to heat and chemicals, allow them to be used in everything from construction materials to advanced composites and even in the automotive industry.

Understanding the cenosphere meaning is key to appreciating their industrial potential. In simple terms, cenospheres are a type of hollow, light particle that acts as a filler material. Their application spans many industries, such as construction, where they are used to produce lightweight concrete, coatings, and paints. In the aerospace sector, cenospheres are employed in the manufacturing of composite materials for aircraft parts. Their ability to provide significant weight reduction without compromising strength makes them invaluable in these high-performance applications.

Additionally, cenospheres are used in oil well drilling, where they help to improve the strength and durability of drilling fluids. Their insulating properties make them highly sought after in the production of thermal and sound insulation materials. Overall, the cenospheres' versatility across industries is a major factor in their growing popularity.

The Role of Cenospheres Manufacturers in the Global Market

The market for cenospheres has been steadily expanding, driven by the demand from various industries for lightweight materials that offer enhanced performance characteristics. Cenospheres manufacturers play a crucial role in providing high-quality products that meet the specific needs of their clients. These manufacturers source cenospheres from coal fly ash and process them to create consistent, high-quality microspheres that are used in a wide range of applications.

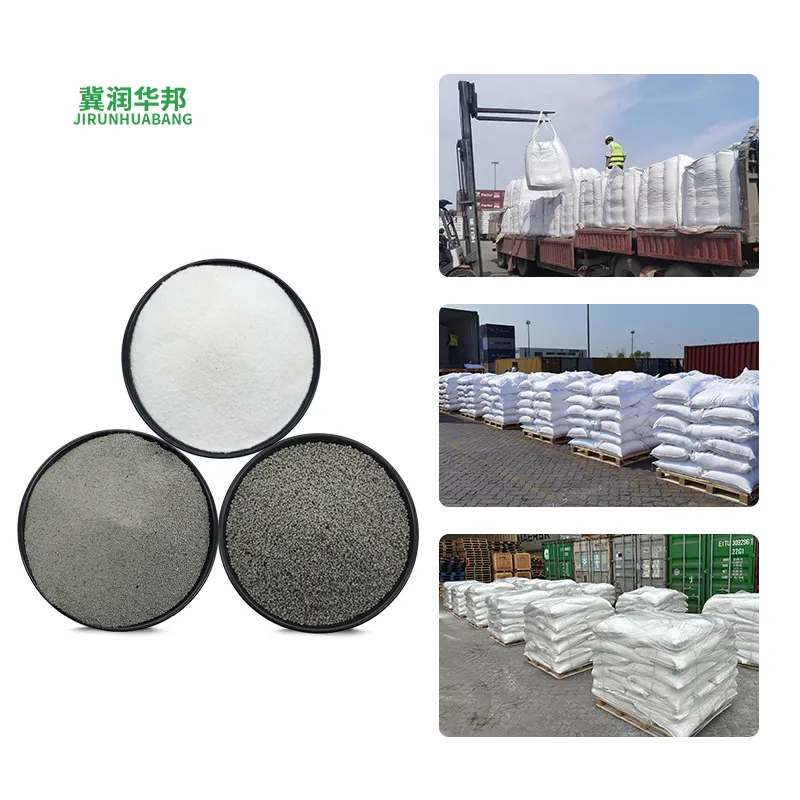

Cenospheres manufacturers are involved in producing different grades of cenospheres, which vary based on factors like particle size, density, and chemical composition. This enables the manufacturers to cater to a broad spectrum of industries, from construction to aerospace, where precise material specifications are required. Some cenospheres manufacturers also offer specialized processing to produce products with specific characteristics, such as increased strength or enhanced resistance to heat.

The presence of cenospheres manufacturers in regions with large coal combustion industries is crucial for meeting global demand. These manufacturers not only provide cenospheres for industrial applications but also contribute to sustainability by recycling coal fly ash, which would otherwise be a waste product. By transforming this waste material into valuable industrial products, cenospheres manufacturers play a pivotal role in reducing environmental impact.

Factors That Influence Cenosphere Price in the Market

The cenosphere price is influenced by several factors, including the quality of the cenospheres, the size of the batch being purchased, the supplier's location, and market demand. Since cenospheres are a byproduct of coal combustion, the price is also affected by the supply of coal fly ash. As global efforts to reduce carbon emissions and promote cleaner energy sources grow, the availability of fly ash may become more limited, which could drive up the cenosphere price in the future.

Another key factor influencing cenosphere price is the level of processing involved. Some cenospheres are processed to meet specific standards, such as being refined for use in high-performance materials like composites or specialized coatings. This processing can add to the cost of the cenospheres, particularly when custom specifications are required for specialized industrial applications. Furthermore, as demand for cenospheres increases in sectors such as aerospace and automotive manufacturing, competition among suppliers may affect pricing dynamics.

The cost of transportation also plays a significant role in determining the cenosphere price, especially for bulk orders. Since cenospheres are lightweight, shipping costs are often lower than for heavier materials, but for larger orders or international shipments, logistics costs can still contribute to the final price.

The Growing Demand for سنوسفرها in Advanced Materials

سنوسفرها are increasingly being recognized as valuable materials for the production of advanced composites, which are used in industries such as aerospace, automotive, and construction. The lightweight nature of cenospheres makes them an excellent choice for producing materials that need to meet strict weight and strength requirements. In the automotive industry, for example, cenospheres are used to create lightweight composites that improve fuel efficiency by reducing vehicle weight.

The demand for cenospheres in aerospace applications is also on the rise. Their unique combination of strength, low density, and heat resistance makes them ideal for use in the production of aircraft components, where minimizing weight is essential. Additionally, cenospheres are used in thermal insulation systems in both the aerospace and construction industries, providing energy efficiency and cost savings in applications ranging from insulation for spacecraft to building materials.

In construction, cenospheres are used as fillers in concrete to create lighter, more durable materials. They are also used in the production of coatings and paints, where their ability to improve the material's resistance to high temperatures and harsh chemicals is highly valued. As the demand for high-performance materials grows across various industries, the role of cenospheres continues to expand, making them a critical component in the development of next-generation technologies.

How to Source the Best Quality سنوسفرها from Reliable Suppliers

When sourcing cenospheres, it's essential to work with reliable suppliers who can provide consistent quality at competitive prices. Several factors should be considered when choosing a supplier, including the supplier's reputation, product quality, and ability to meet specific customer requirements. Quality control is crucial in the production of cenospheres, as inconsistent particle size, density, or chemical composition can affect the performance of the material in industrial applications.

Reliable cenospheres manufacturers will provide detailed specifications for their products, including information about particle size distribution, chemical composition, and any additional processing treatments applied to the cenospheres. It is also essential to verify that the manufacturer adheres to industry standards and regulations to ensure that the cenospheres meet the necessary performance criteria for your applications.

Working with a reputable supplier also means you can expect timely delivery and responsive customer service. Given the growing demand for cenospheres, establishing a long-term relationship with a reliable supplier ensures a steady supply of high-quality materials for your business. This is especially important for industries like aerospace and automotive, where production schedules and performance requirements are critical.

سنوسفرها FAQs

What are cenospheres made of?

سنوسفرها are primarily composed of silica, alumina, and other mineral compounds. They are a byproduct of coal combustion in thermal power plants and are characterized by their hollow, microspherical shape. These particles are lightweight, strong, and heat-resistant, making them ideal for a variety of industrial applications.

How are cenospheres used in the construction industry?

In the construction industry, cenospheres are used as lightweight fillers in concrete to reduce weight while maintaining strength. They are also employed in the production of coatings and paints, offering thermal insulation properties and resistance to high temperatures and chemicals. The use of cenospheres in construction helps improve the durability and energy efficiency of buildings and infrastructure.

What factors affect the cenosphere price?

The cenosphere price is influenced by factors such as the quality of the cenospheres, the level of processing involved, and the demand in various industries. The cost of raw materials (coal fly ash), processing, and shipping also contribute to the final price. Additionally, the cenosphere price can fluctuate depending on market conditions and competition among suppliers.

Can cenospheres be used in the automotive industry?

Yes, cenospheres are increasingly used in the automotive industry to create lightweight composites that reduce vehicle weight and improve fuel efficiency. Their ability to provide strength without adding significant weight makes them a valuable material in the development of high-performance automotive parts.

How do I choose the right cenospheres manufacturers?

When selecting a cenospheres manufacturer, consider factors such as the supplier's reputation, product quality, and ability to meet your specific needs. Look for manufacturers who provide detailed product specifications, adhere to industry standards, and offer competitive pricing. Additionally, choose a supplier with a reliable delivery system and strong customer service to ensure a smooth purchasing experience.