kaolin cost

Back to list

فوریه . 07, 2025 02:00

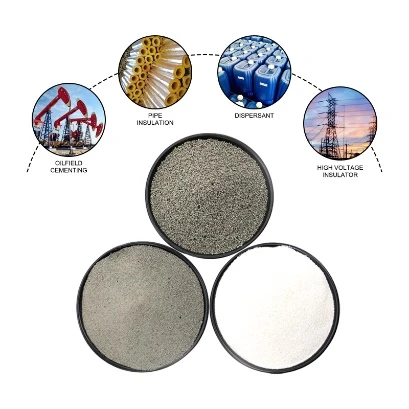

The cost of kaolin, a key industrial mineral, plays a vital role in various sectors such as paper manufacturing, ceramics, paints, and rubber. It serves as a critical component for producers seeking cost-efficiency and reliability in their production processes. Understanding the factors that influence kaolin pricing is essential for businesses to make informed procurement decisions and maintain a competitive edge.

Currency exchange rates can also play a crucial role in determining kaolin costs. As kaolin trade is globally integrated, fluctuations in the value of major currencies can either increase or decrease the purchasing power of importers and exporters. For businesses operating internationally, staying abreast of foreign exchange trends can be instrumental in forecasting cost implications and adjusting budgets accordingly. Technological advancements in kaolin extraction and processing have the potential to influence its cost structure. Innovations aimed at improving mining efficiency, reducing waste, and enhancing product quality could contribute to reduced production costs and, consequently, more competitive pricing. By investing in research and development or forming strategic alliances with cutting-edge technology providers, companies can capitalize on these technological breakthroughs to gain an advantage in sourcing and utilizing kaolin effectively. Environmental sustainability is becoming an increasingly important aspect of the kaolin industry, factoring into cost considerations as well. As consumers and regulators demand stricter adherence to environmental standards, companies that proactively implement eco-friendly mining practices may experience higher initial costs but benefit from long-term savings and brand goodwill. Adopting sustainable practices not only aligns with global environmental goals but also positions businesses as responsible market leaders, appealing to environmentally conscious clients and consumers. In a fiercely competitive market, understanding the intricacies of kaolin cost requires a multi-faceted approach that considers industry trends, geopolitical factors, technological innovations, and sustainability commitments. Businesses that succeed in managing these variables effectively will not only ensure a stable supply chain but also cultivate a reputation for excellence and reliability in their respective industries.

Currency exchange rates can also play a crucial role in determining kaolin costs. As kaolin trade is globally integrated, fluctuations in the value of major currencies can either increase or decrease the purchasing power of importers and exporters. For businesses operating internationally, staying abreast of foreign exchange trends can be instrumental in forecasting cost implications and adjusting budgets accordingly. Technological advancements in kaolin extraction and processing have the potential to influence its cost structure. Innovations aimed at improving mining efficiency, reducing waste, and enhancing product quality could contribute to reduced production costs and, consequently, more competitive pricing. By investing in research and development or forming strategic alliances with cutting-edge technology providers, companies can capitalize on these technological breakthroughs to gain an advantage in sourcing and utilizing kaolin effectively. Environmental sustainability is becoming an increasingly important aspect of the kaolin industry, factoring into cost considerations as well. As consumers and regulators demand stricter adherence to environmental standards, companies that proactively implement eco-friendly mining practices may experience higher initial costs but benefit from long-term savings and brand goodwill. Adopting sustainable practices not only aligns with global environmental goals but also positions businesses as responsible market leaders, appealing to environmentally conscious clients and consumers. In a fiercely competitive market, understanding the intricacies of kaolin cost requires a multi-faceted approach that considers industry trends, geopolitical factors, technological innovations, and sustainability commitments. Businesses that succeed in managing these variables effectively will not only ensure a stable supply chain but also cultivate a reputation for excellence and reliability in their respective industries.

Share

Previous:

Next: