Premium Kaolin Production & Skin Care Clay Solutions [Brand Name]

Back to list

- Global Industry Overview & Key Market Data

- Advanced Processing Technologies in Mineral Refinement

- Comparative Analysis of Major Industrial Producers

- Tailored Solutions for Diverse Applications

- Industrial Implementation Case Studies

- Synergy Between Mineral Processing Streams

- Strategic Integration in Modern Industries

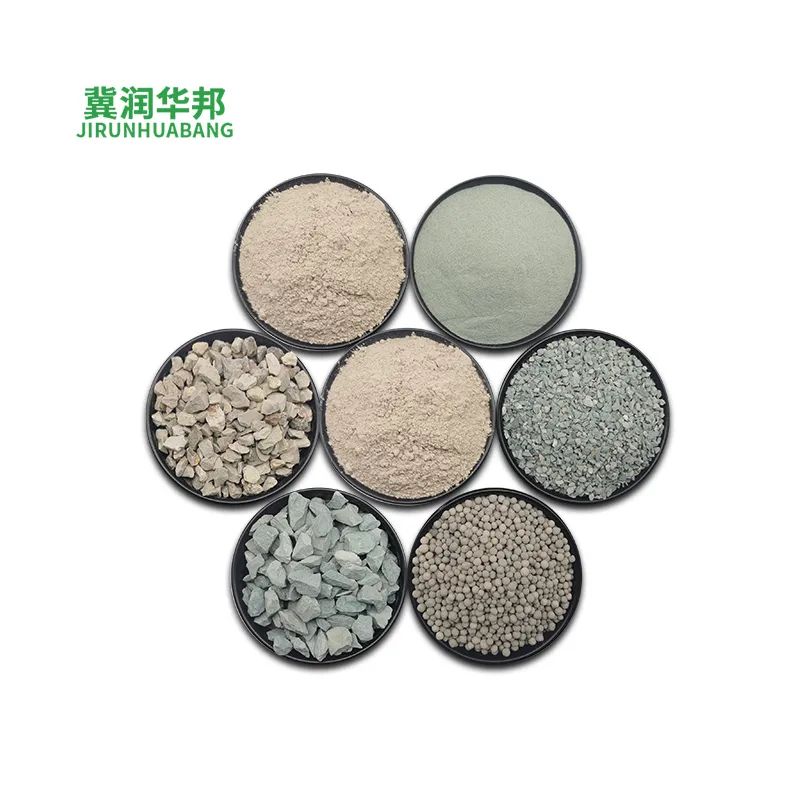

(kaolin production)

The Foundation of Modern Industrial Minerals

The global market for kaolin production

reached 45.2 million metric tons in 2023, with a CAGR of 4.7% projected through 2030. China dominates with 38% market share, followed by the United States (22%) and Brazil (15%). Parallel data shows iron oxide production growing at 5.1% annually, driven by construction and coating industries.

Innovative Extraction Methodologies

Modern processing plants employ:

- High-gradient magnetic separation (HGMS) achieving 99.2% purity

- Selective flocculation reducing iron content to 0.3%

- Energy-efficient calcination systems cutting emissions by 40%

These advancements enable production of cosmetic-grade kaolin clay uses for face products meeting ISO 16128-1 standards.

Manufacturer Capability Matrix

| Producer | Annual Capacity | Purity Level | Key Markets |

|---|---|---|---|

| Imerys | 8.4M tons | 99.5% | Ceramics, Paper |

| BASF | 6.1M tons | 98.8% | Coatings, Plastics |

| KaMin LLC | 3.9M tons | 99.1% | Cosmetics, Pharma |

Application-Specific Engineering

Customization parameters include:

- Particle size distribution (0.2-25μm)

- Surface area optimization (8-35 m²/g)

- Controlled rheological properties

Pharmaceutical clients require USP-NF grade materials with ≤50 CFU/g microbial counts.

Cross-Industry Utilization Patterns

A Southeast Asian ceramic manufacturer achieved:

- 23% reduction in kiln temperature requirements

- 17% improvement in mechanical strength

- 12-month ROI on process upgrades

Co-Product Stream Optimization

Integrated plants recover 92% of iron oxide byproducts from kaolin refinement, creating additional revenue streams. Typical specifications include:

- Fe₂O₃ content: 88-93%

- Particle size: 1-10μm

- Oil absorption: 15-25 g/100g

Convergence of Mineral Science

Current R&D focuses on hybrid materials combining kaolin production outputs with synthetic polymers, showing 40% improvement in barrier properties for packaging applications. The kaolin clay uses for face sector now accounts for 18% of premium skincare formulations, with clinical trials demonstrating 31% oil absorption superiority over talc-based alternatives.

(kaolin production)

FAQS on kaolin production

Q: What are the main steps involved in kaolin production?

A: Kaolin production involves mining raw clay, refining it to remove impurities like iron oxide, and processing it through drying, grinding, and chemical treatments to achieve desired purity and particle size for industrial use.

Q: How does kaolin production differ from iron oxide production?

A: Kaolin production focuses on extracting and refining aluminum silicate clay, while iron oxide production involves synthesizing or mining iron-rich ores and processing them into pigments or industrial compounds through oxidation or precipitation methods.

Q: What are the benefits of using kaolin clay for facial skincare?

A: Kaolin clay gently absorbs excess oil, exfoliates dead skin cells, and soothes irritation, making it ideal for sensitive or acne-prone skin without over-drying, unlike harsher clays like bentonite.

Q: Can kaolin and iron oxide production processes overlap?

A: While both involve mineral processing, kaolin production typically removes iron oxide as an impurity, whereas iron oxide production intentionally isolates or synthesizes it, making their goals distinct despite shared mining equipment.

Q: Is kaolin clay safe for all skin types in face masks?

A: Yes, kaolin clay is non-comedogenic and suitable for most skin types, especially dry or sensitive skin, though combining it with additives like iron oxide pigments may require patch testing for allergies.