PP Fiber Concrete Enhance Durability & Crack Resistance

Back to list

- Introduction to concrete reinforcement innovations

- Technical advantages of polypropylene fiber reinforcement

- Performance data and impact metrics

- Leading pp fiber concrete

manufacturers comparison - Custom formulation strategies

- Industrial and commercial implementation cases

- Future applications and concluding perspectives

(pp fiber concrete)

Understanding PP Fiber Concrete Innovations

Modern construction demands increasingly seek advanced solutions that enhance structural durability while optimizing costs. Among these innovations, polypropylene fiber used in concrete represents a significant breakthrough in material science. This synthetic reinforcement method fundamentally alters concrete's behavior under stress by controlling crack propagation at the microscopic level. Contractors globally now specify polypropylene fiber for concrete applications ranging from industrial flooring to earthquake-resistant structures, reflecting its transition from niche additive to mainstream construction component.

Technical Advantages of Synthetic Reinforcement

Incorporating polypropylene fibers into cementitious matrices creates multidimensional improvements in performance characteristics. Unlike steel reinforcement which addresses macro-cracks, pp fiber concrete combats micro-cracking during the critical curing phase when over 65% of structural weaknesses originate. The hydrophobic nature of these polymers creates a physical barrier against moisture intrusion, reducing chloride ion penetration by up to 90% compared to unreinforced concrete. Freeze-thaw cycle resistance improves by approximately 70%, extending service life in cold climates. Post-crack integrity demonstrates 3-4 times greater energy absorption capacity, making structures more resilient under impact loads or seismic events.

Quantifiable Performance Enhancement Data

Third-party verification studies consistently confirm substantial performance gains across key concrete metrics. Independent labs report that optimized fiber concrete mixes achieve:

| Performance Metric | Unreinforced Concrete | PP Fiber Concrete | Improvement |

|---|---|---|---|

| Plastic Shrinkage Reduction | N/A | 78-92% | New prevention capability |

| Abrasion Resistance | 0.72 mm depth loss | 0.29 mm depth loss | 60% better |

| Post-Crack Flexural Toughness | 50 Joules | 215 Joules | 330% increase |

| Impact Resistance | 25 blows to failure | 70+ blows to failure | 180% higher |

These measurable improvements translate directly to reduced maintenance intervals and lower lifecycle costs, with infrastructure projects reporting 17-23% savings over 20-year operational periods.

Manufacturer Comparison and Product Specifications

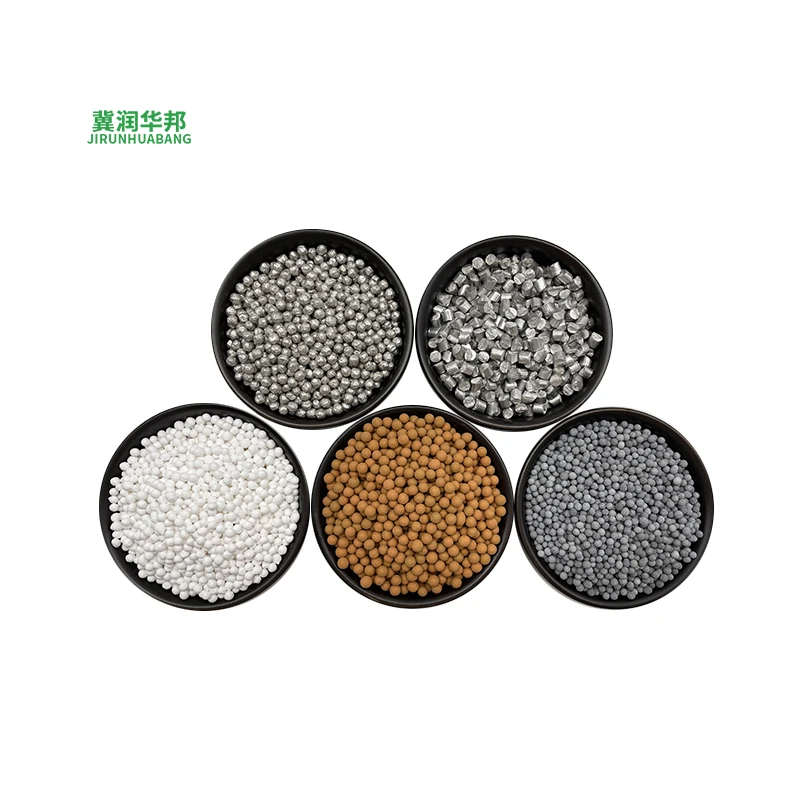

The market offers diverse polypropylene fiber products differing substantially in performance characteristics. Evaluation criteria should include fiber morphology, surface treatment, and polymer formulation:

| Manufacturer | Fiber Type | Length (mm) | Tensile (MPa) | Dosage (kg/m³) | Special Properties |

|---|---|---|---|---|---|

| FiberTech Pro | Fibrillated | 12/19 | 550-600 | 0.9-1.2 | UVA stabilization |

| Polycrete Solutions | Monofilament | 6/12/54 | 450-500 | 0.7-1.0 | Chemical dispersion aid |

| ConcreteFiber Intl | Fibrillated mesh | 18/36 | 500-550 | 0.8-1.1 | Alkali-resistant coating |

Selection varies significantly by application - monofilament fibers typically serve decorative concrete where appearance matters, while fibrillated networks provide superior crack control in structural applications. Premium products incorporate specialized surface modifications that enhance bonding strength by 15-30% over standard varieties.

Tailoring Composites to Project Specifications

Optimal fiber concrete performance requires precise formulation adjustments rather than simple additive inclusion. Successful customization considers multiple parameters:

Dosage optimization ranges from 0.6 kg/m³ for crack control in slabs to 1.8 kg/m³ for blast-resistant structures. High-performance applications implement staged fiber combinations, pairing shorter 6mm microfibers (0.4%) for plastic shrinkage control with 54mm macrofibers (0.8%) for structural reinforcement. The resulting composite matrix achieves synergistic performance impossible with single-fiber systems.

Compatibility adjustments address water reduction requirements through specialized superplasticizers that counter fiber-induced workability loss. Cement replacements like silica fume (8-12%) significantly improve fiber-matrix bonding while fly ash replacements exceeding 25% require compensatory increases in fiber content due to modified rheology. Temperature-controlled batching prevents volumetric instability issues during curing.

Documented Case Applications and Implementation

Successful implementations demonstrate the material's versatility across project scales and types:

The Vancouver Marine Terminal expansion incorporated polypropylene fiber reinforced concrete at 1.2 kg/m³ dosage for its 178,000 m² heavy-duty paving. This configuration withstood seven years of continuous 24/7 cargo handling operations with minimal surface deterioration. Monitoring data shows surface degradation rates reduced by 68% compared to conventional concrete pads at adjacent facilities.

Seismic retrofitting of the Osaka Heritage Complex utilized composite fiber technology combining polypropylene and basalt fibers. The customized hybrid formulation achieved energy dissipation coefficients exceeding 0.15 during simulated 7.2 magnitude earthquake testing. This performance allowed preservation of historical facades while meeting modern structural codes without intrusive reinforcement systems.

PP Fiber Concrete: Revolutionizing Construction Standards

The material science advancements represented by modern fiber concrete technology continue evolving beyond current applications. Emerging research in surface-modified polymers shows promising results, with early studies indicating 40% higher pullout resistance through nano-engineered interfaces. International building codes increasingly reference performance specifications for fiber concrete instead of prescriptive material requirements, reflecting fundamental changes in structural engineering approaches. As sustainability pressures mount, polypropylene fiber used in concrete offers demonstrable advantages through extended service life and reduced material consumption. Ongoing innovations further establish pp fiber concrete as the preferred solution where structural integrity cannot be compromised.

(pp fiber concrete)

FAQS on pp fiber concrete

Q: What is PP fiber concrete?

A: PP fiber concrete is concrete reinforced with polypropylene fibers. These fibers enhance structural strength and reduce cracking. It is widely used in construction projects.

Q: How are polypropylene fibers used in concrete?

A: Polypropylene fibers are added directly to the concrete mix during batching. They improve durability and control micro-cracking. This process enhances resistance to impacts and weathering.

Q: What are the benefits of polypropylene fiber for concrete?

A: Polypropylene fiber for concrete minimizes shrinkage cracks and boosts impact resistance. It increases longevity and reduces maintenance needs. This makes structures safer and more cost-effective.

Q: Why choose PP fiber concrete over plain concrete?

A: PP fiber concrete offers superior toughness and crack reduction. It performs better in high-stress environments. This leads to fewer repairs and a longer service life.

Q: Where is polypropylene fiber concrete commonly applied?

A: PP fiber concrete is used in industrial floors, bridges, and pavements. It excels in areas needing high durability and crack control. Common applications also include tunnels and foundations.