different types of kaolin clay

Back to list

ফেব্রু. . 10, 2025 09:49

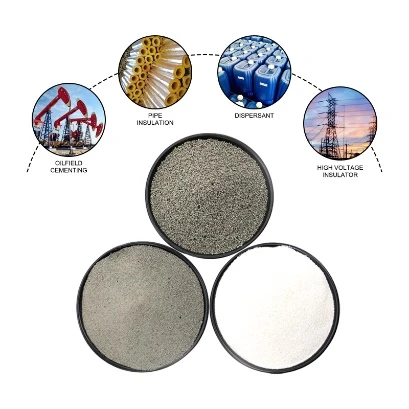

Kaolin clay, a versatile natural substance, boasts a range of types, each with its unique properties and uses. These variations arise from geological differences and processing methods, offering distinct benefits across various industries. The efficacy of kaolin clay in diverse applications can significantly enhance the credibility of businesses that integrate it into their product lines. In this exploration of different types of kaolin clay, the focus will be on understanding their unique features, their applications, and the potential benefits for businesses.

Finally, metakaolin is a distinctive type derived from the dehydroxylation of kaolinite. Known for its pozzolanic properties, metakaolin becomes highly reactive when mixed with lime in mortars or concrete applications, leading to enhanced strength and durability. Construction industries favor metakaolin for producing sustainable and resilient building materials. Businesses leveraging the specialized properties of each type of kaolin clay can gain a competitive edge. For example, manufacturers in the paper industry capitalize on calcined kaolin’s brightness to produce superior paper products that appeal to publishers and commercial printers. Similarly, cosmetic companies create premium skincare lines using the purity of water-washed kaolin, driving brand trust and customer loyalty. In the field of rubbers and plastics, integrating air-floated kaolin can lead to products that not only meet but exceed industry standards for quality and performance. For car manufacturers, using surface-modified kaolin can lead to innovative solutions that cater to modern demands for sustainability and efficiency. Construction firms incorporating metakaolin into building materials can market their products as eco-friendly alternatives, meeting the growing consumer demand for green construction. The versatility of kaolin clay is not merely limited to its physical and chemical properties; it extends to its capacity to enhance product portfolios, ensuring businesses remain authoritative and competitive in their markets. Firms can deliver superior performance, improved aesthetics, and sustainable solutions by understanding the diverse types and applications of kaolin clay, establishing trust and demonstrating expertise to their customer base. As knowledge around different types of kaolin clay continues to evolve, staying informed and adaptable becomes a strategic imperative for businesses aiming to maintain their authoritative position in relevant industries. Through strategic sourcing and innovative application, companies can leverage the unique characteristics of each kaolin type to innovate and fortify their market presence, ensuring a trusted and reliable product offering to their consumers.

Finally, metakaolin is a distinctive type derived from the dehydroxylation of kaolinite. Known for its pozzolanic properties, metakaolin becomes highly reactive when mixed with lime in mortars or concrete applications, leading to enhanced strength and durability. Construction industries favor metakaolin for producing sustainable and resilient building materials. Businesses leveraging the specialized properties of each type of kaolin clay can gain a competitive edge. For example, manufacturers in the paper industry capitalize on calcined kaolin’s brightness to produce superior paper products that appeal to publishers and commercial printers. Similarly, cosmetic companies create premium skincare lines using the purity of water-washed kaolin, driving brand trust and customer loyalty. In the field of rubbers and plastics, integrating air-floated kaolin can lead to products that not only meet but exceed industry standards for quality and performance. For car manufacturers, using surface-modified kaolin can lead to innovative solutions that cater to modern demands for sustainability and efficiency. Construction firms incorporating metakaolin into building materials can market their products as eco-friendly alternatives, meeting the growing consumer demand for green construction. The versatility of kaolin clay is not merely limited to its physical and chemical properties; it extends to its capacity to enhance product portfolios, ensuring businesses remain authoritative and competitive in their markets. Firms can deliver superior performance, improved aesthetics, and sustainable solutions by understanding the diverse types and applications of kaolin clay, establishing trust and demonstrating expertise to their customer base. As knowledge around different types of kaolin clay continues to evolve, staying informed and adaptable becomes a strategic imperative for businesses aiming to maintain their authoritative position in relevant industries. Through strategic sourcing and innovative application, companies can leverage the unique characteristics of each kaolin type to innovate and fortify their market presence, ensuring a trusted and reliable product offering to their consumers.

Share

Previous:

Next: