Bulk Talc Powder Wholesale High Purity & Industrial Uses

Back to list

- Industry Insights: The Growing Demand for Bulk Minerals

- Performance Advantages: Why Talc Excels in Industrial Applications

- Supplier Comparison: Technical Specifications Analysis

- Custom Processing Solutions for Industrial Needs

- Material Characteristics: From Particle Size to Chemical Composition

- Application Case Studies Across Manufacturing Sectors

- Procurement Strategies for Bulk Talc Powder

(talc bulk)

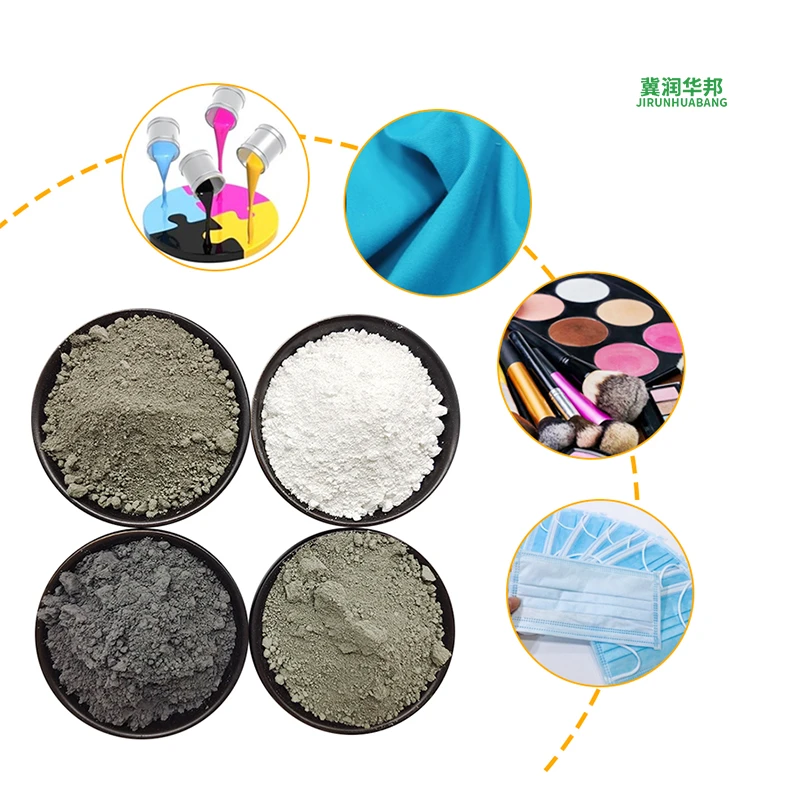

The Essential Role of Talc Bulk in Modern Industries

Industrial sectors increasingly rely on mineral solutions that deliver both performance and cost efficiency. Talc powder in bulk quantities has become a fundamental material across manufacturing processes globally. Recent market analysis from Grand View Research indicates the talc industry will reach $3.2 billion by 2027, with bulk material purchases driving 68% of volume growth. Production facilities benefit from bulk talc powder for sale through consistent supply chains that eliminate material variability. Packaging innovations now allow 25-ton shipments with moisture-proof barriers that preserve purity during transit. Companies requiring bulk talc achieve up to 30% operational savings compared to bagged alternatives through automated handling systems.

Performance Advantages: Why Talc Excels in Industrial Applications

Engineered mineral properties make bulk talc powder indispensable across sectors. The material's platelet structure provides reinforcement in polymer composites, increasing tensile strength by 40-60% at 30% filler loading. Thermal stability up to 900°C enables ceramic applications while maintaining dimensional integrity. Production managers favor talc powder bulk for its hydrophobic nature that reduces moisture absorption in plastics manufacturing by 70-80% compared to alternative fillers. Rheological modification properties allow precise viscosity control in paint formulations, enabling spray applications without sagging. These technical characteristics translate to longer product lifespans and reduced rejection rates on production lines.

Supplier Comparison: Technical Specifications Analysis

| Supplier | Whiteness Index | Median Particle Size (µm) | SiO₂ Content | Moisture (%) | Production Certification |

|---|---|---|---|---|---|

| Alpha Minerals | 94.5 | 6.8 | 61.2% | 0.12 | ISO 9001, REACH |

| Beta Resources | 92.1 | 9.3 | 58.7% | 0.18 | ISO 14001 |

| Gamma Industrial | 96.2 | 5.2 | 63.1% | 0.09 | ISO 9001, FDA |

Custom Processing Solutions for Industrial Needs

Leading suppliers now offer advanced modification services for bulk talc powder tailored to specific applications. Surface treatment options include silane coatings that improve polymer adhesion by 75% in automotive composites. Precision milling achieves particle distributions targeting D90 below 5μm for coating applications requiring ultra-fine textures. Some facilities provide calcined variants where thermal processing at 650-800°C enhances material hardness for engineering plastics. Dedicated production lines accommodate custom blend requests, incorporating additives like antimicrobial agents for medical-grade compounds. These specialized services reduce downstream processing costs by 15-22% while ensuring material compatibility with existing production parameters.

Material Characteristics: From Particle Size to Chemical Composition

Performance consistency begins with geological sourcing and material processing. Premium deposits yield magnesium silicate compositions with 92-97% purity, containing minimal carbonate inclusions that affect thermal stability. Advanced beneficiation techniques eliminate accessory minerals through multi-stage flotation, achieving iron oxide content below 0.5% for high-brightness applications. Particle morphology directly influences functional properties - platy structures with aspect ratios exceeding 20:1 provide superior reinforcement in polypropylene. Recent advances in air classification allow suppliers to maintain strict particle size distributions where 98% of material falls within ±3μm of target specifications, ensuring batch-to-batch consistency.

Application Case Studies Across Manufacturing Sectors

Automotive manufacturers have reduced dashboard component weights by 23% using talc-reinforced polypropylene in bulk quantities. A tier-one supplier achieved this while maintaining impact resistance above 9 kJ/m² at -30°C. In architectural paints, manufacturers utilizing premium bulk talc powder extended outdoor durability to 15+ years by reducing chalking through optimized particle packing. The paper coating industry documented 35% reductions in energy consumption when substituting traditional fillers with high-brightness talc due to reduced drying temperatures. Pharmaceutical companies have leveraged micronized variants in tablet coatings, where the material's lubricity properties increased production speeds by 18% while maintaining USP/EP compliance standards.

Procurement Strategies for Bulk Talc Powder

Securing reliable talc bulk

supplies requires technical evaluation beyond basic pricing considerations. Production managers should establish quality verification protocols including XRF analysis for composition and laser diffraction testing for particle distribution. Contracts with volume commitments of 500+ metric tons typically secure 12-15% cost advantages while guaranteeing allocation during material shortages. Regional logistics planning reduces transportation expenses, with bulk talc powder for sale shipped in specialized containers featuring fluidization systems for direct transfer to silos. Leading industrial zones now feature bonded warehouses enabling just-in-time delivery with inventory management services. These approaches transform raw material procurement into a competitive advantage while ensuring manufacturing consistency.

(talc bulk)

FAQS on talc bulk

以下是为核心关键词[talc bulk]及相关词创建的5组英文FAQ,使用HTML富文本格式:What is bulk talc used for in manufacturing?

Q: What industrial applications require talc bulk purchases?

A: Bulk talc powder is essential in plastics, ceramics, and paint production where it acts as a filler and reinforcing agent. Its moisture resistance and thermal stability make it ideal for automotive parts and construction materials. Large-scale manufacturers buy talc powder bulk to reduce production costs.

How is bulk talc powder different from retail packaging?

Q: Why choose bulk talc powder over small packaged options?

A: Bulk talc powder comes in industrial quantities (500kg+ sacks or silos) with 30-50% cost savings versus retail packs. It features customized micron sizes for specific applications like paper coating or pharmaceuticals. Volume buyers also get dedicated quality certificates per shipment.

What quality standards apply to bulk talc for sale?

Q: How is bulk talc powder quality verified before purchase?

A: Reputable suppliers provide ASTM E11-compliant certification confirming magnesium silicate content (>95%) and asbestos-free status. Particle size analysis (typically 5-45 microns) and whiteness index (92%+) are guaranteed. Safety data sheets include heavy metal test reports.

Where can I source FDA-approved bulk talc powder?

Q: Which suppliers offer compliant bulk talc powder for cosmetics?

A: Select distributors provide USP-grade bulk talc powder with FDA 21 CFR §177 compliance certificates. Pharmaceutical and cosmetic-grade options undergo sterilization and meet strict microbial limits. Always request current GMP documentation for personal care applications.

What packaging options exist for bulk talc purchases?

Q: How is talc bulk shipped for industrial use?

A: Standard options include 1-ton super sacks with weather-resistant liners or 25kg poly-lined kraft bags. For extreme volumes, pneumatic tanker trucks deliver directly to silos. Custom moisture-proof packaging with desiccants ensures product integrity during transit.