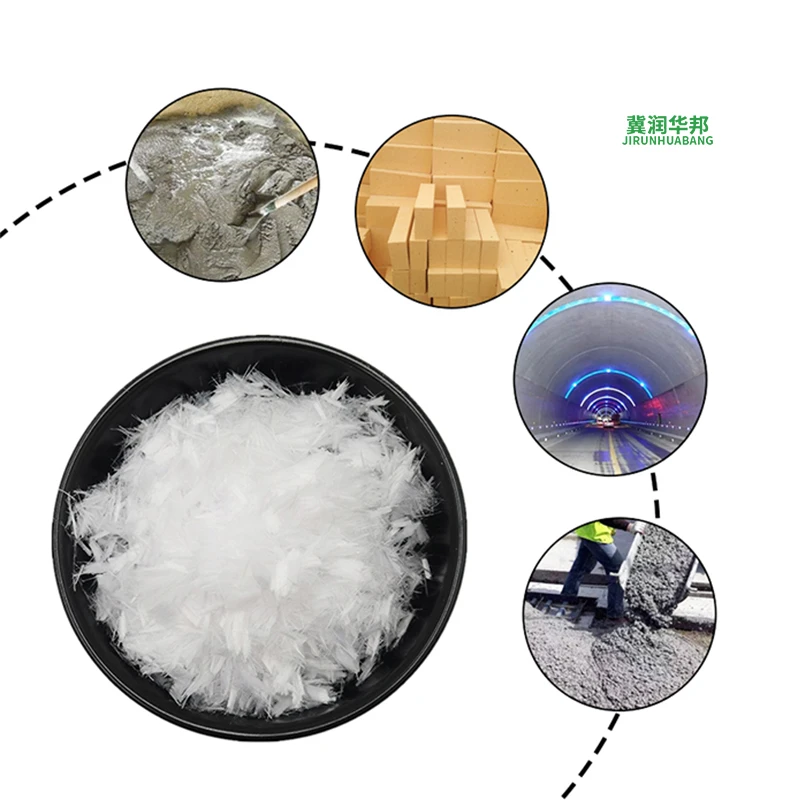

industrial talc

Back to list

فبراير . 16, 2025 06:09

Industrial talc, a versatile mineral widely used across various sectors, is increasingly gaining attention for its unique properties. Talc, primarily composed of magnesium silicate, is renowned for its softness, hydrophobicity, and ability to reduce friction. It is these distinct characteristics that make it an invaluable component in industries such as plastics, ceramics, paint, paper, and personal care.

Trustworthiness is paramount when selecting industrial talc suppliers. It is vital to partner with companies that are not only transparent about their sourcing and processing methods but also committed to upholding environmental and health standards. Reputable suppliers often adhere to international safety regulations, such as the REACH regulations in Europe, and provide detailed documentation, including Material Safety Data Sheets (MSDS), to assure clients of product safety. Certifications from recognized bodies further substantiate the credibility of these suppliers, providing assurance that the talc supplied is free from asbestos and other contaminants. Incorporating industrial talc into product solutions is a strategic decision that requires careful consideration of the mineral’s properties and the credibility of suppliers. As industries evolve and consumer demands shift towards sustainability and performance, the role of talc as a multifunctional additive continues to expand. Whether in enhancing the quality of everyday products or contributing to innovative material solutions, industrial talc stands as a testament to the power of natural minerals in advancing technological growth and efficiency. As businesses seek to optimize their production processes, leveraging the unique properties of industrial talc offers a competitive edge. Beyond its traditional uses, the mineral is increasingly being explored for applications in cutting-edge fields such as pharmaceuticals and agriculture, where its inertness and ability to improve substance flow can be particularly beneficial. The ongoing research and collaboration within the field showcase industrial talc as not just a raw material but as a catalyst for innovation. In conclusion, industrial talc exemplifies the intersection of natural resources and technological advancement. Its versatility and utility across multiple domains underscore its importance in contemporary manufacturing and product development. By focusing on experience, expertise, authoritativeness, and trustworthiness, stakeholders can harness the full potential of industrial talc, leading to enhanced products and sustainable practices that benefit industries and consumers alike.

Trustworthiness is paramount when selecting industrial talc suppliers. It is vital to partner with companies that are not only transparent about their sourcing and processing methods but also committed to upholding environmental and health standards. Reputable suppliers often adhere to international safety regulations, such as the REACH regulations in Europe, and provide detailed documentation, including Material Safety Data Sheets (MSDS), to assure clients of product safety. Certifications from recognized bodies further substantiate the credibility of these suppliers, providing assurance that the talc supplied is free from asbestos and other contaminants. Incorporating industrial talc into product solutions is a strategic decision that requires careful consideration of the mineral’s properties and the credibility of suppliers. As industries evolve and consumer demands shift towards sustainability and performance, the role of talc as a multifunctional additive continues to expand. Whether in enhancing the quality of everyday products or contributing to innovative material solutions, industrial talc stands as a testament to the power of natural minerals in advancing technological growth and efficiency. As businesses seek to optimize their production processes, leveraging the unique properties of industrial talc offers a competitive edge. Beyond its traditional uses, the mineral is increasingly being explored for applications in cutting-edge fields such as pharmaceuticals and agriculture, where its inertness and ability to improve substance flow can be particularly beneficial. The ongoing research and collaboration within the field showcase industrial talc as not just a raw material but as a catalyst for innovation. In conclusion, industrial talc exemplifies the intersection of natural resources and technological advancement. Its versatility and utility across multiple domains underscore its importance in contemporary manufacturing and product development. By focusing on experience, expertise, authoritativeness, and trustworthiness, stakeholders can harness the full potential of industrial talc, leading to enhanced products and sustainable practices that benefit industries and consumers alike.

Share

Previous:

Next: