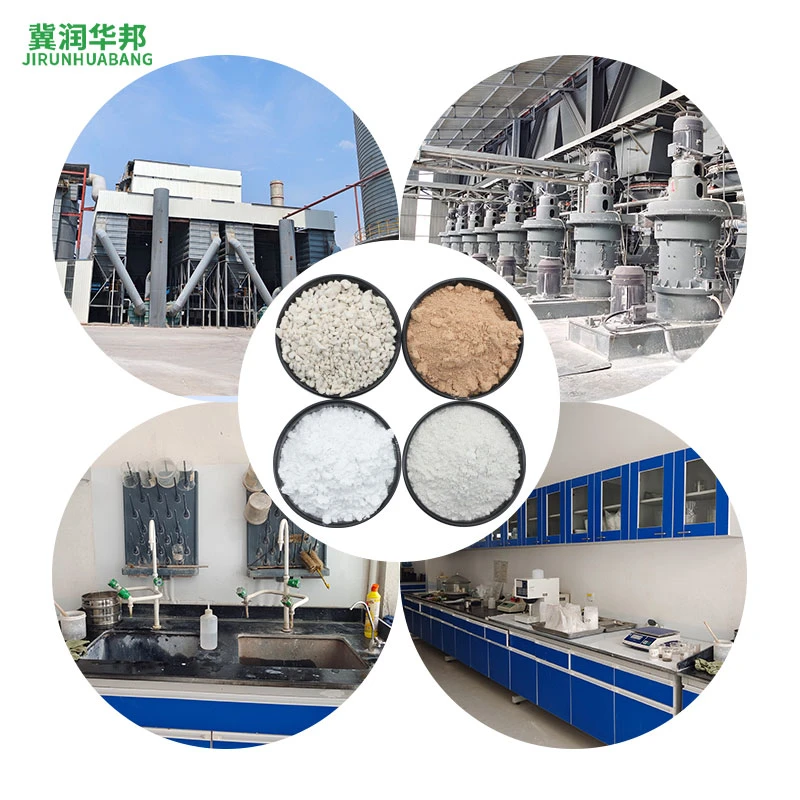

Industrial Talcum Powder Suppliers High-Purity & Cost-Effective Solutions

Back to list

- Industrial Talcum Powder: An Essential Material for Diverse Applications

- Technical Advantages and Performance Data

- Comparative Analysis of Leading Industrial Talc Powder Suppliers

- Tailored Solutions: Custom-Engineered Talc Products

- Real-World Application Impact Across Key Industries

- Quality Assurance and Safety Standards in Talc Production

- Selecting Reliable Industrial Talc Powder Suppliers for Long-Term Success

(industrial talcum powder)

Industrial Talcum Powder: The Backbone of Modern Manufacturing

Industrial talcum powder, a hydrated magnesium silicate mineral, serves as a critical performance enhancer across manufacturing sectors. Derived from high-purity talc deposits, this engineered material exhibits unique lamellar particle structures measuring 5-20 micrometers. Approximately 65% of global production serves industrial applications, with specialty grades demanding strict particle size distributions under ISO 3262 standards. Leading talc processors now apply precision micronization techniques to achieve median particle sizes below 10μm, enabling optimized rheological control in applications ranging from polymer modification to ceramics. Annual consumption data shows a consistent 4.3% CAGR since 2020, underscoring its indispensable role across industrial value chains.

Technical Superiority Driving Industry Adoption

The material's dominance stems from multifaceted technical advantages exceeding alternative mineral fillers. In polymer applications, surface-modified talc improves tensile strength by 40-60% compared to calcium carbonate equivalents while maintaining optimal melt flow indices. Rigorous ASTM testing confirms heat deflection temperature improvements exceeding 30°C in polypropylene composites. For paints and coatings, lamellar talc particles reduce critical pigment volume concentration by 15% while enhancing scrub resistance through barrier formation. Recent innovations include submicron talc dispersions increasing ceramic green strength by 25% and reducing sintering temperatures by up to 100°C, significantly lowering energy consumption during firing.

Supplier Comparison: Global Market Leaders

Specialized industrial talc powder suppliers operate under distinct technical capabilities, geographic strengths, and product profiles:

| Supplier | Specialization | Production Capacity | Key Specifications | Certification Level |

|---|---|---|---|---|

| Supplier A | High Purity Plastics Grade | 500,000 MT/year | Median particle size: 2.5μm | ISO 9001, IATF 16949 |

| Supplier B | Surface Modified Coatings Grade | 300,000 MT/year | Brightness: 92% ISO | ISO 14001, REACH |

| Supplier C | Ceramics & Specialty Grades | 200,000 MT/year | SiO₂ Content: >58% | FDA Compliant |

| Supplier D | Multi-Industrial Applications | 400,000 MT/year | Oil Absorption: 40-60g/100g | ISO 45001, Halal |

Leading providers offer distinct value propositions, with European suppliers dominating specialty plastic reinforcement talcs while Asian producers capture 63% of the ceramics market. Supplier selection requires alignment between technical specifications like particle morphology and specific application requirements.

Customized Product Engineering Approach

Advanced suppliers deliver tailored industrial talc powder solutions through integrated processing techniques. A prominent polymer manufacturer recently achieved 17% material cost savings through customized talc development involving:

1. Particle architecture optimization via multi-stage classification

2. Surface energy modification using organosilane chemistries

3. Tightened size distribution curves targeting d₉₀ under 8μm

4. Proprietary thermal treatment enhancing lamellarity index to 0.87

Such engineered variants now enable auto part manufacturers to meet OEM impact resistance standards while reducing wall thickness by 1.2mm, significantly decreasing per-part weight and material costs.

Documented Application Performance Metrics

Industrial talc demonstrates transformative impacts across sectors:

Polymer Compounds: PP homopolymer reinforcement with 20% talc loading improved flexural modulus to 3,800 MPa while reducing warpage in injection molded parts by 32% compared to neat resin formulations.

Coatings Systems: Epoxy formulations incorporating platelet talc achieved 2,000+ hours in salt spray testing (ASTM B117) through optimized barrier protection exceeding conventional fillers.

Technical Ceramics: Alumina-talc composites (15% loading) demonstrated 180 MPa cold crushing strength alongside reduced firing shrinkage to 0.3% in kiln tests.

Construction Materials: Self-leveling underlayment mortars incorporating hydrophobic talc reduced water absorption below 4.5% according to EN 13813 standards.

Rigorous Quality Management Framework

Premium industrial talc powder suppliers implement comprehensive quality protocols validated through:

• Continuous monitoring of 18 elemental impurities meeting EUPIA and FDA standards

• Advanced laser diffraction particle sizing guaranteeing <±1.5μm batch consistency

• Dedicated quality testing laboratories performing 27 distinct analytical methods

• Blockchain-tracked material documentation ensuring supply chain transparency

• Batch-specific certificates of analysis confirming purity, heavy metal content, and mineralogical composition

Such stringent controls guarantee compliance with pharmaceutical applications where magnesium trisilicate pharmacopeia standards demand consistent SiO₂ content between 43-46%.

Selecting Industrial Talc Powder Suppliers for Success

Identifying high-performance industrial talcum powder

requires comprehensive technical qualification beyond basic pricing. Leading procurement teams utilize a systematic framework incorporating:

• Material testing protocols aligning with ISO 3262 standard annex requirements

• Evaluation of micronization capabilities against application-specific fineness targets

• Verification of specialized processing expertise through site audits

• Assessment of analytical capabilities via proficiency testing programs

• Review of sustainability certifications including life cycle assessment data

Partnerships with technically competent industrial talc powder suppliers prove invaluable when developing formulations to overcome emerging performance gaps. The most successful collaborations involve structured co-development programs where processors share application challenges while suppliers deliver solutions tailored to exact technical requirements.

(industrial talcum powder)

FAQS on industrial talcum powder

Q: What are the main differences between industrial talcum powder and calcium carbonate powder?

A: Industrial talcum powder is a magnesium silicate-based material prized for its lubricity and heat resistance, while calcium carbonate powder is a calcium-based compound used for cost-effective bulk filling and pH stabilization. Their applications vary based on chemical composition and physical properties.

Q: How to identify reliable industrial talc powder suppliers?

A: Look for suppliers with certifications like ISO, MSDS documentation, and proven industry experience. Verify their product purity levels (e.g., 95%+ talc content) and request samples to test performance in your specific application, such as plastics or ceramics manufacturing.

Q: What are the top industrial uses of talcum powder?

A: Key applications include polymer production (improving flow properties), paint/coating formulations (anti-settling agent), and ceramics (thermal shock resistance). It also serves as a lubricant in rubber manufacturing and a dust suppressant in construction materials.

Q: Can calcium carbonate powder replace industrial talcum powder?

A: While both are fillers, calcium carbonate lacks talc's heat resistance and lubricity. It's preferred in paper coating and acid-neutralizing applications. Substitution depends on technical requirements like temperature exposure and desired material flexibility.

Q: Are there safety regulations for industrial talcum powder handling?

A: Yes, OSHA requires respiratory protection for airborne particles and skin protection during bulk handling. Suppliers must provide safety data sheets, and users should adhere to local regulations regarding crystalline silica content (if present) and workplace exposure limits.